76

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

7

Process data

SEW Unit Profile

7.1

Process data

Process data (PD)

are all time-critical (realtime) data of a process that have to be

processed or transmitted quickly. They are characterized by high dynamic properties

and actuality. Process data are, for example, setpoints and actual values of the drive

inverter, but also peripheral states of limit switches. Process data are exchanged

cyclically between programmable controller and drive inverter.

The actual control of the MOVIDRIVE

®

inverter is carried out using process data.

Process input data (PI) and process output data (PO) are basically handled separately.

This means you can specify for your application the kind of output data (setpoints) to be

sent from the controller to the drive inverter and the process input data (actual values)

to be sent by MOVIDRIVE

®

to the higher-level controller.

However, to control the drive inverter via communication interface, the inverter must first

be switched to the relevant control signal source and setpoint source. Distinguishing

between control signal and setpoint source allows for the most various combinations.

For example, the drive can be controlled via fieldbus and uses the analog setpoint as

setpoint. Next, the parameters for describing the process output data are used for

informing the drive inverter how to interpret the received process data.

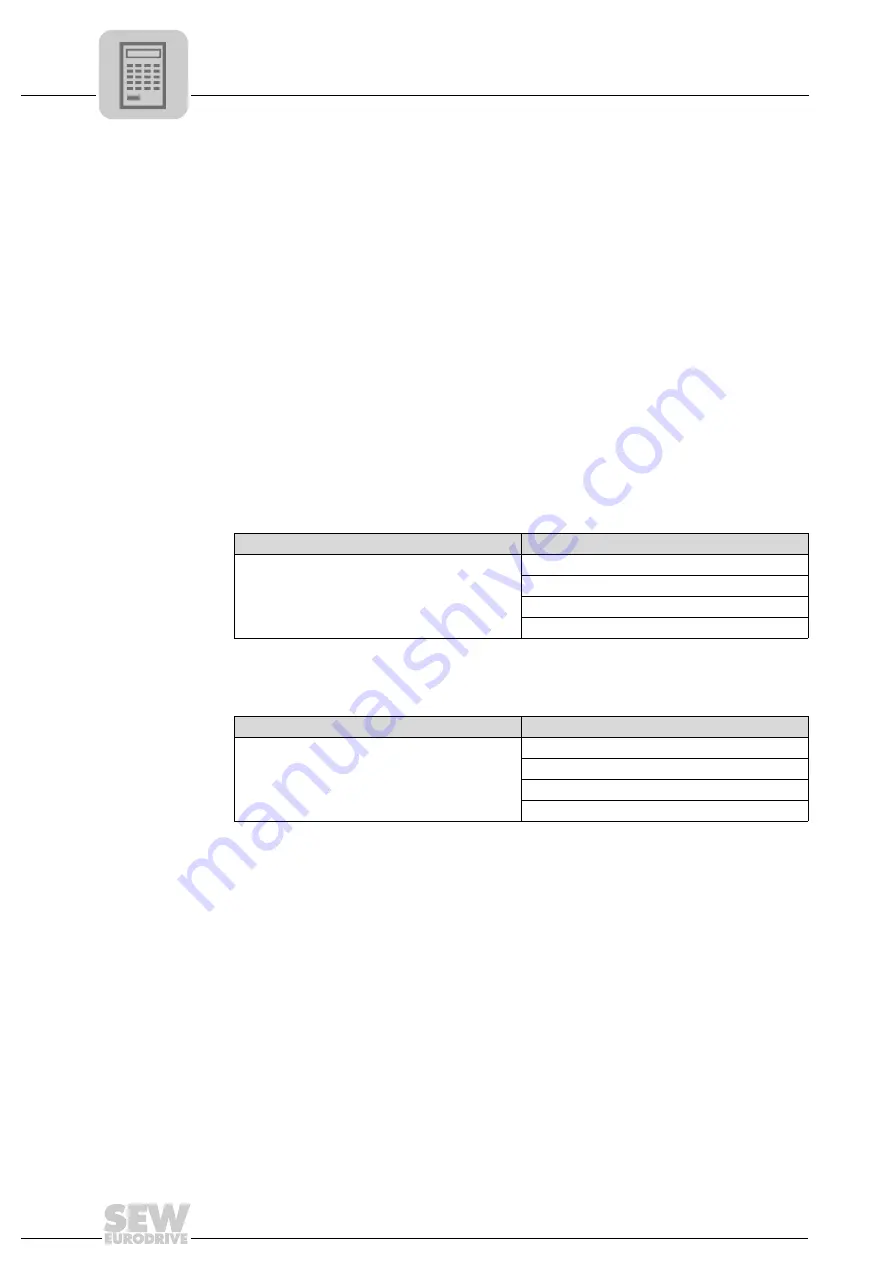

Parameter

P100 setpoint source

is used to specify the communication interface which

the drive inverter uses for processing the setpoint.

Parameter

P101 control signal source

is used to specify how the drive inverter is

controlled. The inverter expects the control world of the source set in this parameter.

Setting:

TERMINALS

With this setting, the drive inverter is controlled using only binary inputs and, if required,

using the IPOS

plus®

control program.

Setting: RS485,

FIELDBUS, SBus

With this setting, the control word defined in the process output data channel is updated

by the set control signal source (RS485 / FIELDBUS / system bus).

The binary inputs and the IPOS

plus®

control program continues to be involved in the

control.

Parameter

Communication interface

P100 Setpoint source

RS485

Fieldbus

SBus

...

Parameter

Inverter control via

P101 Control signal source

Terminals

RS485

Fieldbus

SBus

Summary of Contents for MOVIDRIVE MDX60B

Page 2: ...SEW EURODRIVE Driving the world...

Page 142: ......

Page 143: ...SEW EURODRIVE Driving the world...