78

Manual – MOVIDRIVE® MDX60B/61B Communication and Fieldbus Unit Profile

7

Process data configuration

SEW Unit Profile

7.2

Process data configuration

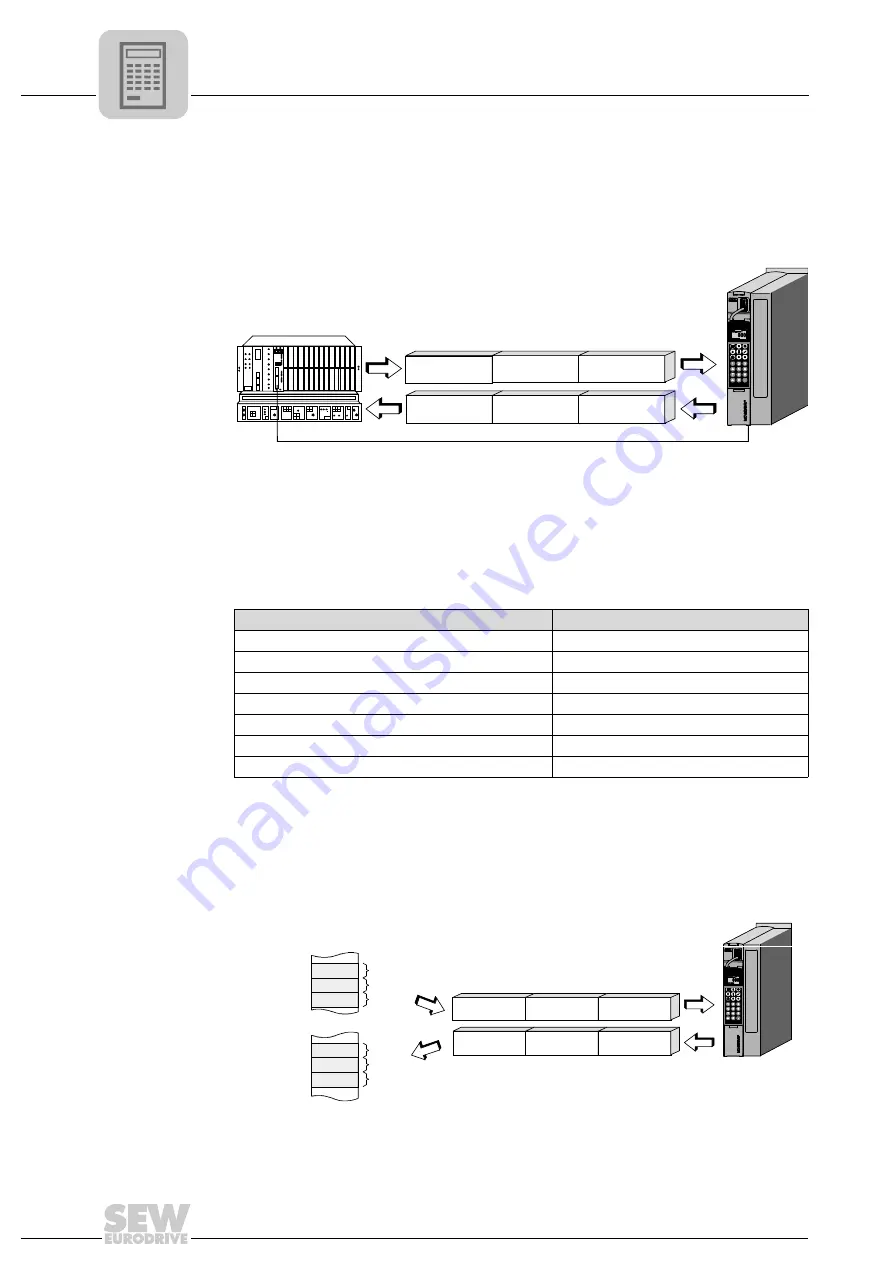

The MOVIDRIVE

®

inverter can be controlled with 1 to 10 (with RS485 with 1 to 3)

process data words via the communication interfaces. The number of process input data

(PI) and process output data (PO) is identical.

The process data configuration is set using DIP switches on the option card (e.g.

DFI11B) or via the SBus master when starting up the bus system (e.g. PROFIBUS-DP

or RS485). In this way, the inverter is automatically set properly. You can use the keypad

or the MOVITOOLS

®

MotionStudio fieldbus monitor to check the current process data

configuration under the menu item

P090 Fieldbus PD configuration

.

Depending on the installed fieldbus option card, the following process data configura-

tions might take effect.

Only the number of process data (that is 1 PD - 10 PD) is interesting for process data

control of the drive inverter. These process data are usually mapped in the I/O or periph-

eral area when programmable logic controllers are used as fieldbus master. This means

the I/O or peripheral area of the PLC must provide sufficient memory space for the drive

inverter’s process data (see following figure). The address between process data of the

drive inverter and the PLC address area is usually assigned on the fieldbus master

module.

54943AXX

P090 PD configuration

1 process data word + parameter channel

1PD+PARAM

1 process data word

1PD

2 process data words + parameter channel

2PD+PARAM

2 process data words

2PD

....

....

10 process data words + parameter channel

10PD+PARAM

10 process data words

10PD

55022AEN

PA 1

PA 2

PA

PA 3

PE 1

PE 2

PE

PE 3

PO 1

PO 2

PO

PO 3

PI 1

PI 2

PI

PI 3

PLC address range

AW 40

AW 42

AW 44

EW 40

EW 42

EW 44

PO 3

PO 2

PO 1

PI 3

PI 2

PI 1

Summary of Contents for MOVIDRIVE MDX60B

Page 2: ...SEW EURODRIVE Driving the world...

Page 142: ......

Page 143: ...SEW EURODRIVE Driving the world...