Operating Instructions – MOVIFIT® FDC

131

Index

Index

A

ABOX

Hybrid.................................................................12

Hybrid, activating terminals................................51

Hybrid, bus systems.....................................63, 65

Hybrid, description .................................17, 62, 64

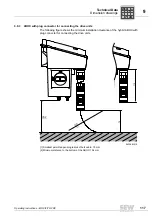

Hybrid, dimension drawings.............................115

Hybrid, SNI cable connection.......................52, 53

Hybrid, variants ............................................63, 65

Maintenance switch ...........................................18

MTA...-S04.-...-00, description ...........................50

MTA...-S04.-...-00, screw fittings........................50

MTA...-S04.-...-00, types....................................50

MTA...-S54.-...-00, description ...........................62

MTA...-S54.-...-00, plug connector positions......63

MTA...-S54.-...-00, types....................................63

MTA...-S64.-...-00, description ...........................64

MTA...-S64.-...-00, plug connector positions......65

MTA...-S64.-...-00, types....................................65

Nameplate..........................................................22

Standard ............................................................12

Standard, activating terminals............................51

Standard, bus systems ......................................50

Standard, description ...................................17, 50

Standard, dimension drawings.........................115

Standard, SNI cable connection ..................52, 53

Standard, variants..............................................50

Type designation................................................22

Variants, overview..............................................12

Accessories

Cables................................................................66

Activating terminals................................................51

Actuator module .....................................................16

Application Configurator.........................................93

B

Binary inputs ........................................................107

Binary outputs ......................................................107

Blaning plugs .........................................................32

Blanking plugs (wet areas).....................................35

C

Cables, available............................68, 70, 72, 82, 83

Cables, prescribed ...............................................111

Cables, recommended .........................................113

CAN bus

Cables................................................................74

Connection.........................................................74

Connection examples ........................................84

Technical data .................................................108

CE marking ..........................................................104

Closing mechanism ...............................................29

Communication & control unit, technical data......107

Configuration .........................................................93

Configuring units....................................................93

Connecting supply system leads ...........................40

Connection

AC 400 V output ................................................69

AC 400 V output (DSC) .....................................71

AC 400 V output (SNI) .......................................67

CAN bus ............................................................74

CAN bus (connection examples) .......................84

DRC ...........................................56, 57, 67, 69, 71

Ethernet fieldbus interface .....................60, 80, 81

Ethernet service interface ..................................79

EtherNet/IP ............................................60, 80, 81

Installation topology ...............................46, 47, 48

I/O plug connector .............................................76

I/O terminals ................................................58, 59

Laptop................................................................92

Line terminals ....................................................54

Modbus/TCP..........................................60, 80, 81

MOVIGEAR

®

.............................56, 57, 67, 69, 71

PC......................................................................92

PE ................................................................38, 41

PROFINET.............................................60, 80, 81

RS485 plug connector .......................................75

RS485 terminals ..........................................58, 59

Safety Notes ........................................................9

SBus plug connector..........................................74

SBus terminals.............................................58, 59

SBus (connection examples) .............................84

SNI cable .....................................................52, 53

SNI plug connector ............................................67

SNI terminals

USB interface.....................................................78

24 V terminals....................................................55

Connection cables .................................................66

Connection cables, available .........68, 70, 72, 82, 83

Connection cables, prescribed ......................82, 111

Summary of Contents for MOVIFIT FDC

Page 2: ...SEW EURODRIVE Driving the world...

Page 137: ...Operating Instructions MOVIFIT FDC 137 Index Y Y adapter 77 0 9 24 V terminals connection 55...

Page 138: ......

Page 139: ......