5

Electrical installation

Installation planning taking EMC aspects into account

Operating Instructions – MOVIFIT

®

MC

36

5.2.1

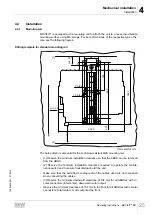

Equipotential bonding

Regardless of the PE connection, it is essential that low-impedance,

HF-capable

equipotential bonding

is provided (see also EN 60204-1 or DIN VDE 0100-540):

• Establish a connection over a wide surface

area between the MOVIFIT

®

mounting rail

and the system (untreated, unpainted, un-

coated mounting surface).

• To do so, use a ground strap (HF litz wire) to

connect MOVIFIT

®

and the system's ground-

ing point.

[1]

[3]

[2]

[4]

9007200851970059

[1] Conductive connection over a large area

between MOVIFIT

®

unit and the mounting

plate

[2] PE conductor in the supply cable

[3] 2nd PE conductor via separate terminals

[4] EMC-compliant equipotential bonding, for

example using a ground strap (HF litz wire)

• Do not use the cable shields of data lines for equipotential bonding.

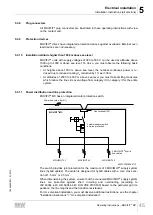

5.2.2

Data lines and 24 V supply

Route data lines and 24 V supply separately from cables that emit interference (such

as control cables of solenoid valves, motor cables).

5.2.3

Connection between MOVIFIT

®

and MOVIMOT

®

Only use hybrid cables from SEW

‑

EURODRIVE for the connection between

MOVIFIT

®

and MOVIMOT

®

.

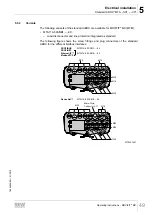

5.2.4

Line shields

• Must have good EMC properties (high screening attenuation)

• May not serve only as mechanical protection for the cable

• Must be connected to a wide area of the unit's metal housing at the cable ends

(see also chapter "Connecting the PROFIBUS cable" (

19484828/EN – 01/2015