14

MOVITRAC

®

31.. – FRS 31

4

Parameters

• The terminal to which

“FRS slave start”

is assigned controls the synchronous start-up of

master and slave if:

– the inputs from the master’s binary outputs with the function “rotating field on” receive a

signal and

– the setpoint/stop function (P 180) at master and slave become active.

• The terminal to which

“FRS Teach-in”

is assigned enables cut lengths (P 765) for the

“Flying

Saws”

application to be entered. This can be implemented using modes 3 and 5. The input of

cut lengths through a binary signal provides a solution in cases where the inverter cannot be

accessed by the user.

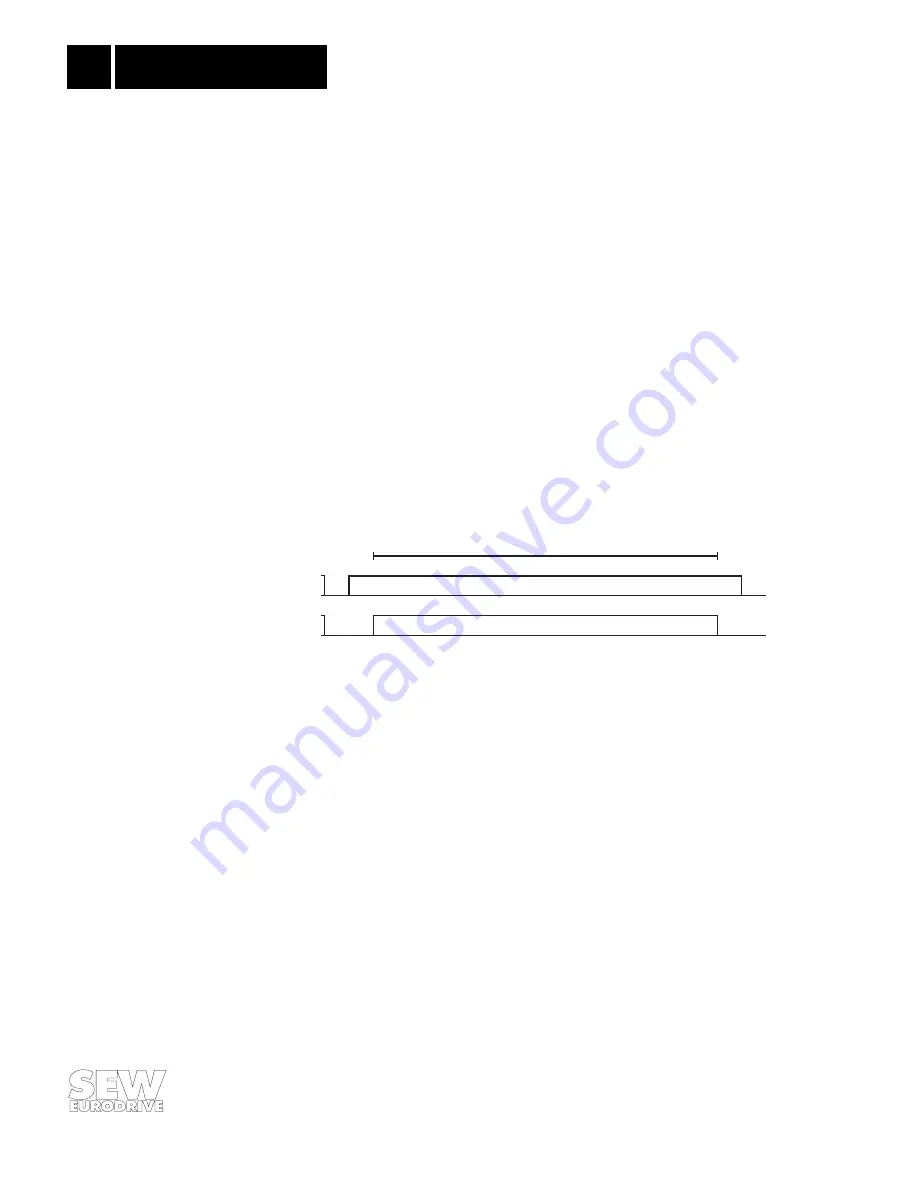

To enter cut lengths, the following actions are necessary:

– the binary input assigned “FRS teach-in” must have a “0" signal

– switch drive to free-running via terminal 102

– length entered will be determined by reference points 1 and 2

– approach reference point 1

– switch “FRS teach-in” terminal to “1"

– approach reference point 2

– switch “FRS teach-in” terminal to “0"

– switch drive to synchronous operation (terminal 102 = “0")

– value entered for P 765 is no longer valid and is indicated by an asterisk

–

00590AEN

Fig. 4: FRS teach function

The drive synchronizes itself afterwards to reference point 2.

Notes on approaching the reference points:

a) approaching the reference points by saw carriage:

is recommended if the lengths to be cut are short. The material to be cut is halted and the saws

travel the length to be cut.

b) approaching the reference point by the material to be cut:

is recommended when the cut lengths are greater than the area in which the sawing operation is

taking place. Set the first reference point to the present cutting position after cutting the material

and halt the saw; start material feed and traverse the material by the required cut length and set

the second reference point.

FRS Teach In

"1"

"0"

"1"

"0"

Reference point 2

Cut length

Reference point 1

Free-running

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com