Operating Instructions – MOVITRAC® B

87

5

Communication and unit profile

Startup

5.11.2 Process data configuration

The MOVITRAC

®

B frequency inverter can be controlled with 1 to 10 (with RS485 with

1 to 3) process data words via the communication interfaces. The number of process

input data (PI) and process output data (PO) is identical.

The process data configuration is set using DIP switches on the option card or via the

SBus master when starting up the bus system (e.g. PROFIBUS-DP or RS485). In this

way, the frequency inverter is automatically given the right setting. You can use the key-

pad or the MOVITOOLS

®

MotionStudio fieldbus monitor to check the current process

data configuration under the menu item

P090 Fieldbus PD configuration

.

Depending on the fieldbus interface in use, the following process data configurations are

active:

Note

: 3 PD for bus cards, 10 PD for FSE24B of the front module type.

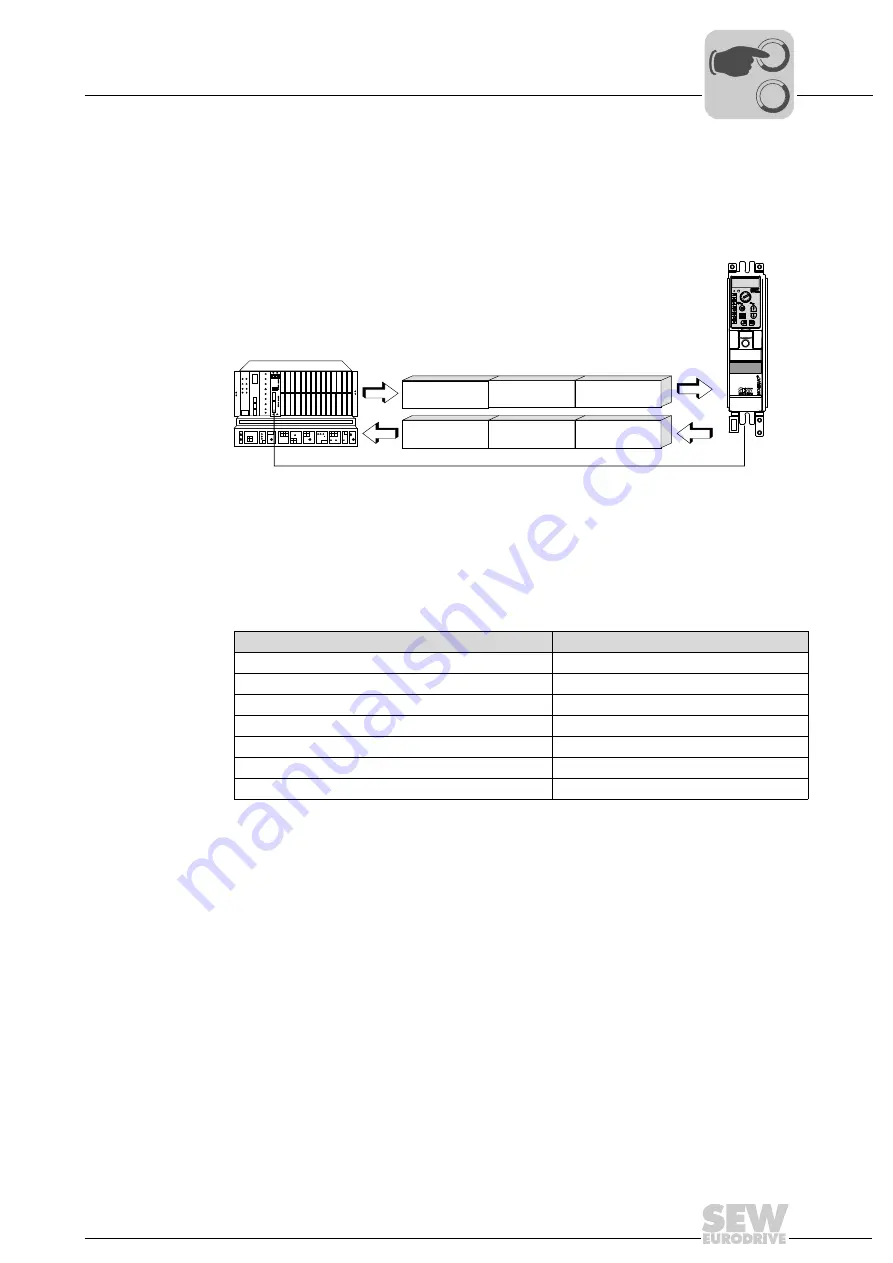

For process data control of the frequency inverter, only the number of process data is

relevant (that is 1PD - 10PD). These process data are usually mapped in the I/O or pe-

ripheral area when programmable logic controllers are used as fieldbus master. This

means the I/O or peripheral area of the PLC must provide sufficient memory space for

the process data of the frequency inverter (see following figure). The address between

process data of the frequency inverter and the PLC address area is usually assigned on

the fieldbus master interface module.

5945505675

P090 PD configuration

1 process data word + parameter channel

1PD+PARAM

1 process data word

1PD

2 process data words + parameter channel

2PD+PARAM

2 process data words

2PD

....

....

10 process data words + parameter channel

10PD+PARAM

10 process data words

10PD

PA 1

PA 2

PA

PA 3

PE 1

PE 2

PE

PE 3

00

I

Summary of Contents for Movitrac B

Page 2: ...SEW EURODRIVE Driving the world...

Page 259: ......