216

Operating Instructions – MOVITRAC® B

8

Technical data for braking resistors, chokes and filters

Technical data

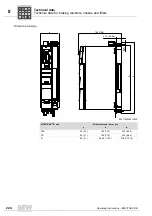

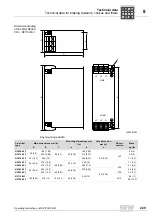

Wire resistors and

grid resistors

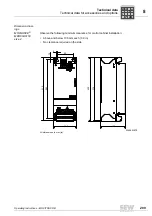

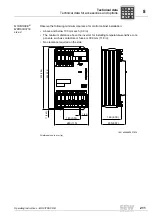

• Perforated sheet cover (IP20) open to mounting surface

• The short-term load capacity of the wire and grid resistors is higher than in the flat-

type braking resistors (

→

chapter "Braking resistor selection")

• A temperature switch is integrated in the BW..-T braking resistor

• A thermal over-current relay is integrated in the BW..-P braking resistor

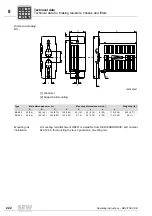

SEW-EURODRIVE recommends implementing additional protection against overload

for the wire and grid resistors by using a bimetallic relay with trip characteristics of trip

class 10 or 10A (in accordance with EN 60947-4-1). Set the trip current to the value I

F

(

→

following tables).

Do not use electronic or electromagnetic fuses because these can be triggered even in

case of short-term excess currents that are still within the tolerance range.

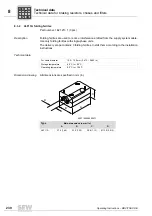

For BW..-T / BW..-P series braking resistors, you can connect the integrated tempera-

ture sensor or the over-current relay using a 2-core, shielded cable as an alternative to

a bimetallic relay. The cable entry for BW..-T and BW..-P series braking resistors can be

run from the front or the back (

→

dimension drawing for BW... / BW..-T / BW..-P braking

resistors). Use filler plugs for tapped holes that are not connected.

The resistor surfaces will get very hot under a load of P

N

. Make sure that you select an

installation site that will accommodate these high temperatures. As a rule, braking resis-

tors are therefore mounted on the control cabinet roof.

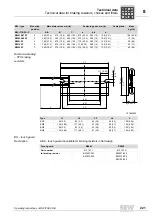

The performance data listed in the following tables indicate the load capacity of the brak-

ing resistors depending on their cyclic duration factor. The cyclic duration factor cdf of

the braking resistor is indicated in % and is based on a cycle duration of

≤

120 s.

P

i

f

kVA

Hz

n

Summary of Contents for Movitrac B

Page 2: ...SEW EURODRIVE Driving the world...

Page 259: ......