5

13

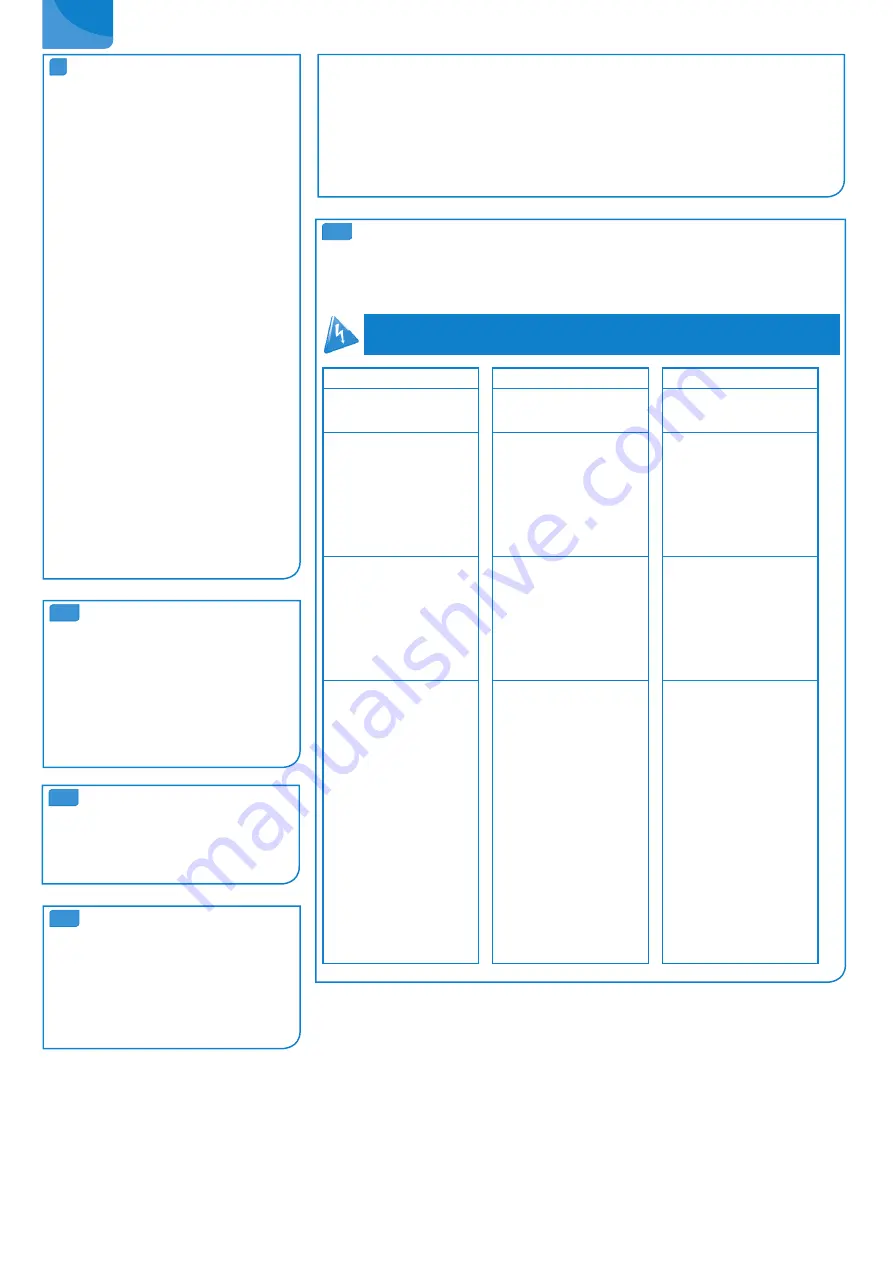

FAULT FINDING

In most cases, any inconsistencies in the operation of the unit will be minor and easy recti-

fied. Please refer to the chart below. If the problem cannot be easily remedied thanks to this

chart, please call our SFA Service organisation or go to a SFA-approved technician.

FAULT OBSERVED

PROBABLE CAUSES

TROUBLESHOOTING

• The motor does not work

• No electricity supply

• Check the control switch

• Check the electrical connections

• Check the power source.

• There is no water inlet for

flushing

• The inlet pipe filter is clogged

• The water inlet pipe is pinched

• The water injection nozzle /

/solenoid valve is clogged

• The switch is wrongly wired up

• Clean the filter

• Check the pipes

• Check the pump

• Check the water injection nozzle

/solenoid valve

• Check the connection of the

cables.

• The motor works but there is

no outlet

• The outlet is clogged

• The outlet is too high

• The through-hull valve is closed

• There is no water in the bowl

• The switch is wrongly wired up

• Dismantle and clean the outlet

• Change the outlet

• Check the pipe routing

• Check the through-hull valve

• Add water to the bowl

• Check the connection of the

cables.

• The motor runs with a rattling

noise

• A hard foreign body has fallen

into the bowl

• Cut the power supply to the

motor.

• Close the through-hull valves

• Remove the motor unit

• Use a hook to remove all

matter that could interfere with the

rotation of the shredder

• Use a tool to rotate the turbine in

both directions until it turns

freely

• Reconnect the power supply to

the motor. and press the «Pump

out» key to check the operation of

the appliance

• Re-open the through-hull valves

• If the macerator is still jammed

we advise you to contact our

ervice department who will be able

to advise you or direct you to one

of our service stations nearest to

your area.

UK

12

GUARANTEE

2 years guarantee from date of purchase,

subject to correct installation and correct use:

disposal of toilet papers and fecal matter only.

Guarantee is limited to replacement or service

of the defective spare parts, and any indemnity

or claim for damages will not be included.

Freight and packing costs, travel expenses are not included in the guarantee. It does not cover any

normal deterioration of the material over time, any external deterioration or accident, incorrect disposal

of sanitary products. Any modification without prior notice will not be under guarantee. Fixing, modifi-

cation, or replacement of parts without our agreement will not be guaranted, and will invalidate it. Our

liability is solely for the product itself.

Guarantee starts from date of purchase we may request a copy of the invoice to validate the purchase

date.

11

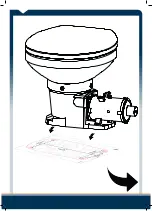

WINTERING

In the event of a long period without use, rinse

the bowl and carry out several flushing cycles

with the fresh water and close through-hull val-

ves.

9

ELECTRICAL

CONNECTION

Advice for wiring up the Sanimarin S:

The maximum recommended voltage drop is

5% or 0.6V for a supply voltage of 12V, and

1.2V for a supply voltage of 24V;

In the event of prolonged absence of supply or

long absence, cut off the water and electricity

supplies to the S.

Electricity supplied consumption per

second:

12V : 0.007 Ah

24V : 0.004 Ah

Current consumption / Fuses:

12V : 300 W / 25 A

24V : 360 W / 15 A

Electric diameter wire:

12V (300 W)

1.5 mm² = 1 m max

2.5 mm² = 2 m max

4 mm² = 3 m max

6 mm² = 4,3 m max

24V (360W)

1.5 mm² = 3,5 m max

2.5 mm² = 6 m max

4 mm² = 9,5 m max

6 mm² = 14 m max

10

CLEANING

For cleaning, use normal sanitary products.

CAUTION:

• Do not use aggressive chemicals (such as

acetone, pure bleach, etc.) that could da-

mage the material of the bowl.

• Use a suitable standard toilet brush; do

not use scouring or abrasive pads.

DISCONNECT THE ELECTRICAL POWER SUPPLY,

BEFORE ATTEMPTING ANY WORK ON THE UNIT.

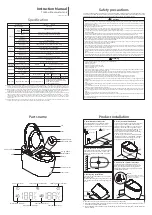

Summary of Contents for SANIMARIN MAXLITE+S

Page 3: ...OR 2 1 4 5 B A 1 1 2 2 1 2 2 1 2 1 2 1 3 4 3 x x x x x x x x x 2Nm MAX 2 2Nm MAX ...

Page 4: ...Ø 25mm int 1 Ø 38mm int 1 1 2 Ø 20mm int 13 16 F F D G J I K F G F C F F OR OR 1 7 9 8 6 ...

Page 5: ...11 10a 0 5m mini 20 WATER H WATER INLET Pdyn 1 7b mini ...

Page 7: ...J M 1 1 2 4 5 2 3 6 1 2 3 6 1 2 4 5 Hand pump toilet replacement POWER BATTERY ...

Page 9: ......

Page 11: ......

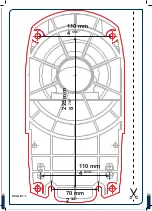

Page 12: ...110 mm 4 5 16 110 mm 4 5 16 225 mm 8 7 8 70 mm 2 3 4 SCALE 1 1 ...

Page 13: ...FR UK 718 11 18 ...

Page 18: ...6 SANIMARIN MAXLITE S NOTES ...