PAGE 25

PAGE 24

MAINTENANCE

Note that using any spark plug other than those

designated may result in the engine failing to operate prop-

erly or in the engine becoming overheated and damaged.

To install the spark plug, first turn the plug until it is fin-

ger tight, then tighten it a quarter turn more with a socket

wrench.

MUFFLER

Inspect periodically for loose fasteners, any damage or corrosion.

If any sign of exhaust leakage is found, stop using the machine and

have it repaired immediately.

Note that failing to do so may result in

the engine catching on fire.

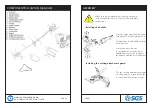

If waste gets stuck and causes blockage

around the intake air cooling vent or

between the cylinder fins, it may cause

the engine to overheat, and that in turn

may cause mechanical failure on the part

of the brushcutter.

MAINTENANCE

PROCEDURE AFTER EVERY 100 HOURS OF USE:

1. Remove the muffler, insert a screwdriver into the vent, and

wipe away any carbon buildup. Wipe away any carbon buildup

on the muffler exhaust vent and cylin-der exhaust port at the

same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has worked its way in be-

tween the clutch lining and drum, and if it has, wipe it away us-

ing oil-free, lead-free gasoline

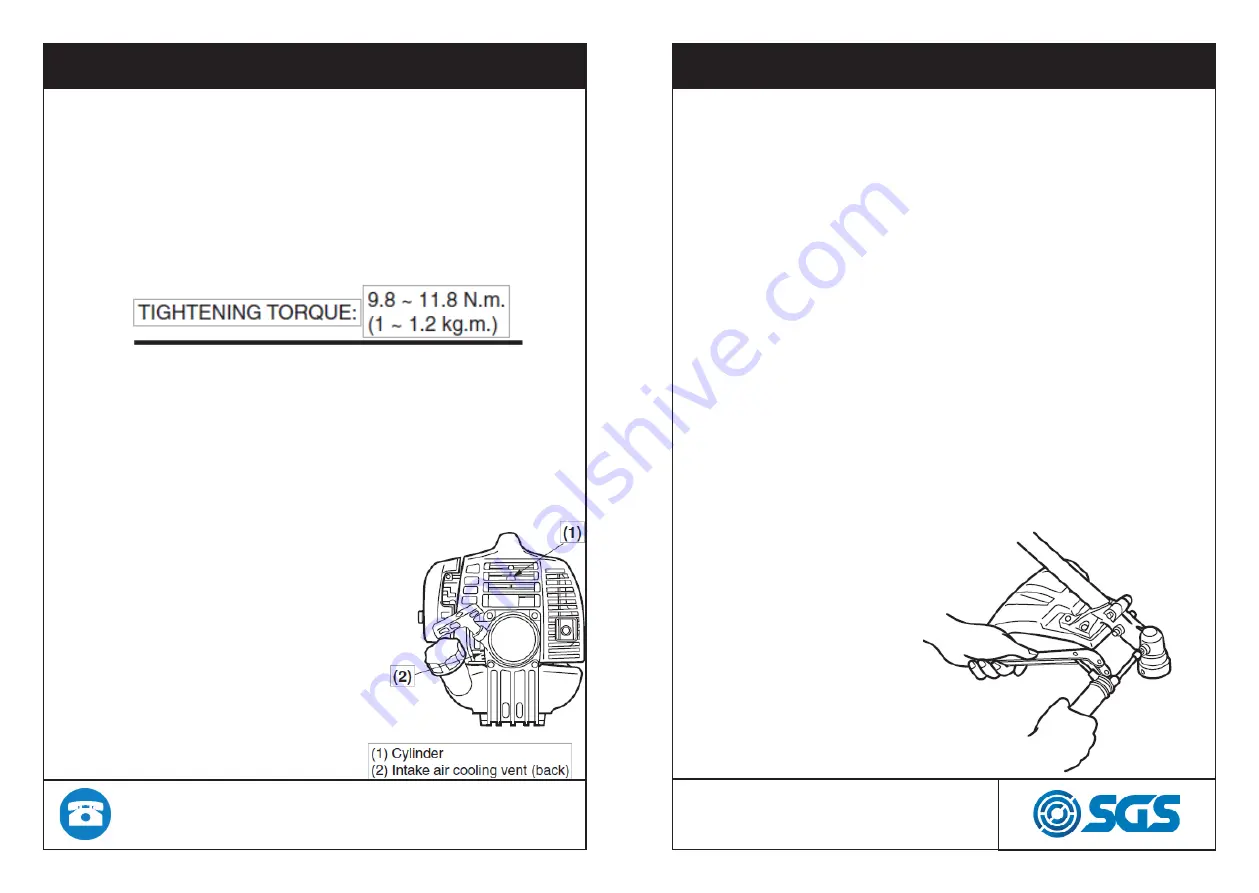

ANGLE TRANSMISSION:

The reduction gears are lubricated by multipurpose, lith-

ium-based grease in the angle transmission. Sup-ply new

grease every 25 hours of use or more often depending on

the job condition.

Remove the cutter

holders before installing

new grease to arrange

for old grease to exit.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850