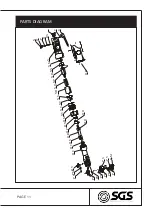

PARTS LIST

PART

DESCRIPTION

QTY

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

Screw nut

O-ring

Spring

O-ring

Bolt

Air inlet

Trigger bolt

Trigger

Main housing

Bearing

Rear plate

Bolt

Rotor

Rotor blade

Cylinder

Front plate

Bearing

Spacer

Gear sleeve

Nut

Gear

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

3

PART

DESCRIPTION

QTY

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Bolt

Gear bracket

Lubricating sleeve

Bias axle

Bearing

Guiding sleeve

Ratchet holder

F/R stem

Spring

Top sleeve

Spacer

Ratchet bracket

Bolt

Ratchet claw

D-type head

Spring

Steel ball

Cushion

Block ring

Soft grip

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.