PAGE 3

PAGE 2

RISK OF EYE OR HEAD INJURY

WHAT COULD HAPPEN

HOW TO PREVENT IT

Air powered equipment and power tools

are capable of propelling materials such as

fasteners, metal chips, sawdust and other

debris at high speed which could result in

serious eye injury.

Always wear approved safety glasses with

side shields.

Disconnect air hose when tool is not in use.

Compressed air can be hazardous.

The air system can cause injury to soft

tissue areas such as eyes and ear. Particles

or objects propelled by the air stream can

cause injury.

For additional protection use an approved

face shield in addition to safety glasses.

Tool attachments can become loose or

break and fly apart, propelling articles at

the operator and others in the work area.

Make sure that any attachments are securely

assembled.

RISK OF FIRE OR EXPLOSION

WHAT COULD HAPPEN

HOW TO PREVENT IT

Abrasive tools such as sanders and grinders,

rotating tools such as drills and impact tools

such as nailers, staplers, wrenches, hammers

and reciprocating saws are capable of gen-

erating sparks which could result in ignition

of flammable materials.

Never operate tools near flammable sub-

stances such as petrol, naphtha, cleaning

solvents etc.

Work in a clean, well-ventilated area free of

combustible materials.

Never use oxygen, carbon dioxide or other

bottled gases as a power source for air tools.

Exceeding the maximum pressure rating of

tools or accessories could cause an explo-

sion resulting in serious injury.

Use compressed air regulated to a maximum

pressure at or below the rated pressure of

any attachments.

Never connect to an air source that is capa-

ble of exceeding 200 psi.

Always verify prior to using the tools that the

air source has been adjusted to the rated air

pressure range.

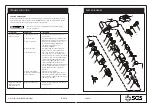

SPECIFICATION

TOOL MODEL

SAT203

CAPACITY

3/8 IN.

FREE SPEED

1800 RPM

AVERAGE AIR CONSUMPTION

6 SCFM

WORKING PRESSURE

90 PSI / 6.3 BAR

AIR INLET

1/4 IN.

AIR HOSE

3/8 IN.

LENGTH X HEIGHT

183 x142 MM

WEIGHT

1.11 KGS

SAFETY GUIDELINES

Please read and fully understand the manual for information relating to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS.

Indicates an immediately hazardous situation which if not

avoided will result in death or serious injury.

DANGER

WARNING

NOTE

Indicates a potentially hazardous situation which if not

avoided could result in death or serious injury.

Alerts the operator to useful information.

SAFETY INSTRUCTIONS

WARNING

DANGER

WWW.SGS-ENGINEERING.COM