PAGE 9

PAGE 8

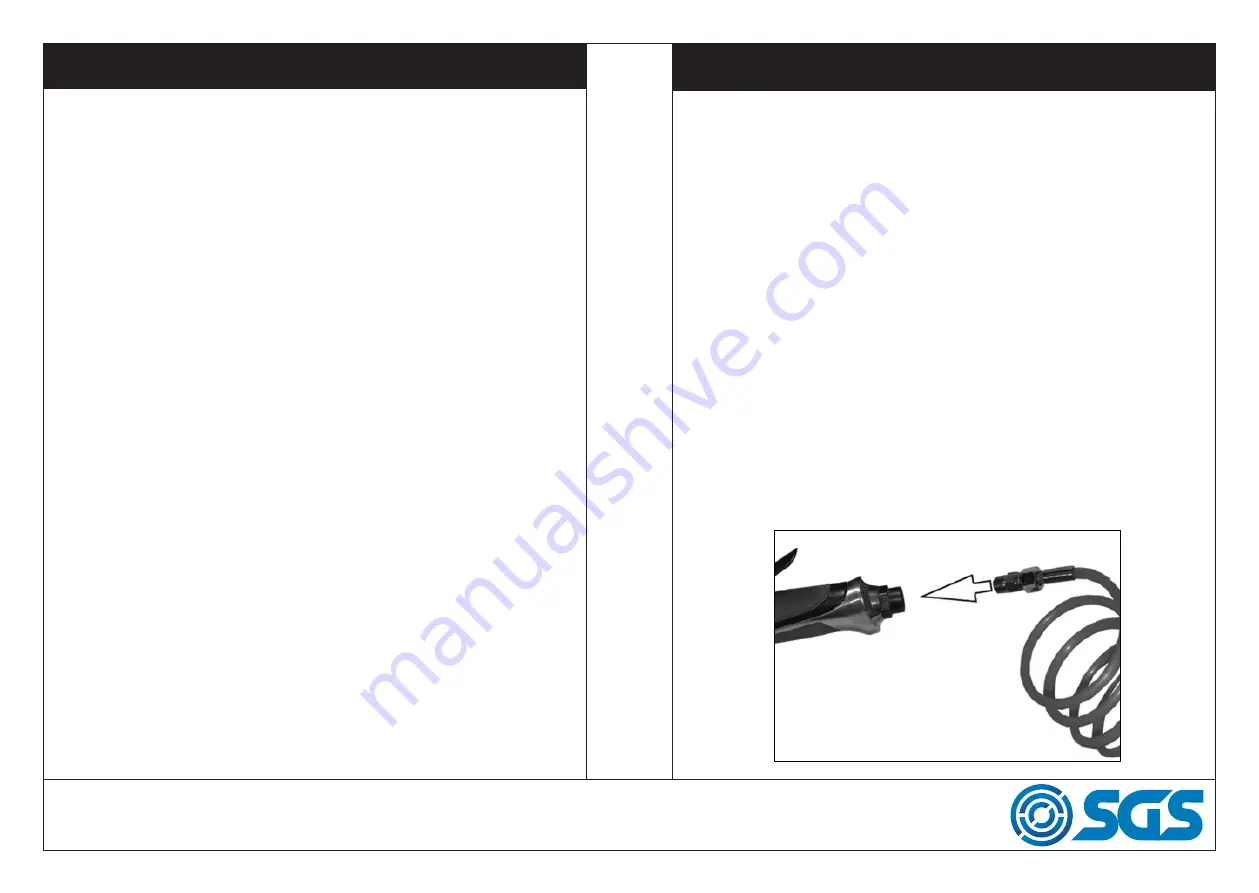

CONNECTING THE AIR SUPPLY

Pour 2-3 drops of airline oil into the air inlet. This should be done regard-

less of whether or not a lubricated air supply is to be used.

Connect a suitable hose to the tool as shown using the airline connector

supplied with the tool.

If required, connect an in-line mini oiler to the tool.

A mini oiler helps to prolong the life of the air tool. Remove the oil fill

screw from the side of the mini oiler and fill with air-line oil

WARNING:

COMPRESSED AIR CAN BE DANGEROUS. ENSURE THAT

YOU ARE FAMILIAR WITH ALL PRECAUTIONS RELATING TO THE USE

OF AIR COMPRESSORS AND COMPRESSED AIR SUPPLY.

If a mini-oiler is not being used, run a few drops of oil through the tool

before use. It can be entered through the inlet strainer or via the hose at

the nearest connection to the air supply.

Connect the other end of the hose to the compressor.

Turn on the air supply and check for air leaks. Rectify any found before

proceeding. PTFE tape may be useful for sealing threaded connections.

Your air tool is now ready for use.

1. Squeeze the trigger against the body of the tool to start the sander

and control the speed. Evaluate the speed and adjust as follows.

2. Adjust the operating speed by twisting the speed control shown. The

speed of rotation is shown by the arrow embossed on the tool body

(anti-clockwise will increase the sanding speed.)

3. To begin work, rest the disc pad on the workpiece and start the

sander. Let the tool do the work. The actual weight of the machine is

normally sufficient for efficient sanding. Do not put additional pres-

sure on the machine, which would only slow down the speed of the

pad, reducing efficiency and placing an additional burden on the mo-

tor.

4. Pass the sander back and forth in wide, overlapping areas, taking care

to keep the sander moving around at all times. Avoid dwelling in one

place for more than a moment.

5. Release the trigger to stop the tool.

6. Always ensure the tool has stopped before putting it down.

ADJUSTING THE SPEED

WWW.SGS-ENGINEERING.COM