18

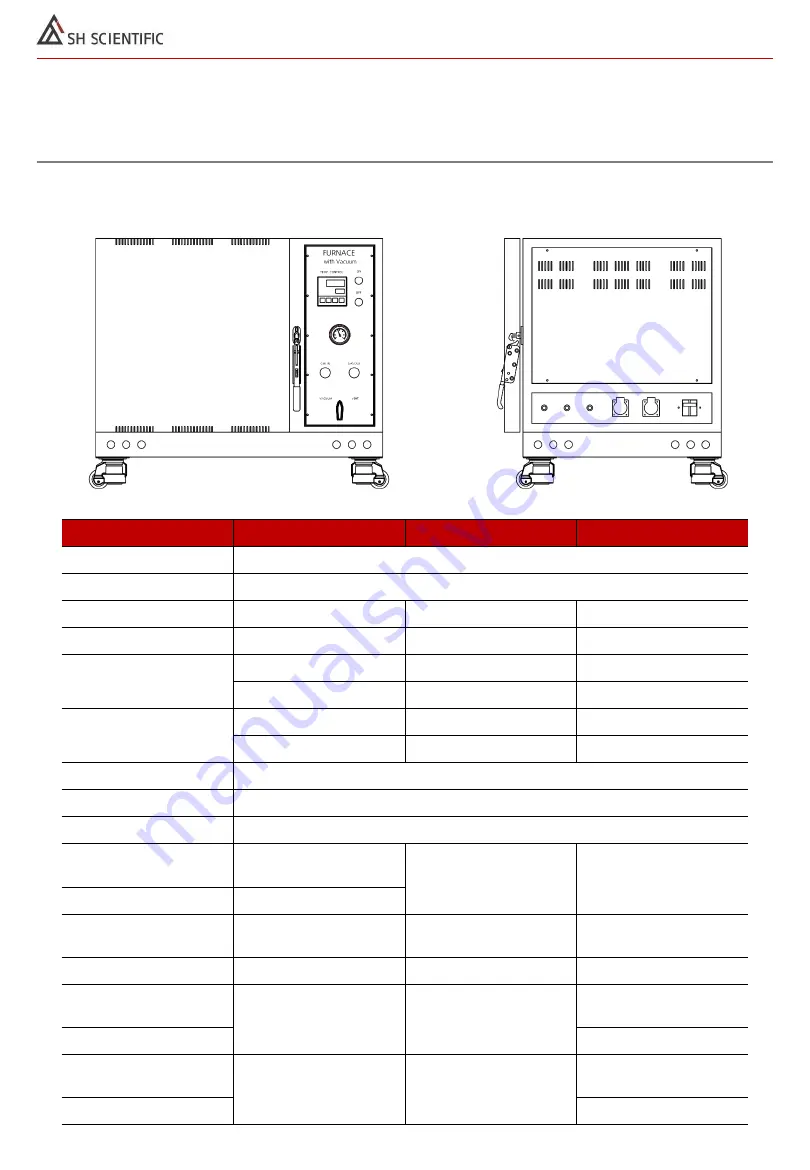

7. Specifications

(

SH-FU-1.5MGV / 10MGV / 31MGV

)

Model

SH-FU-1.5MGV

SH-FU-10MGV

SH-FU-31MGV

Max Temp

1200

℃

(2192

℉

)

Temp Controller

Programmable Controller(SP590)

Heater Capa

1100 W

3000 W

6000 W

Capa

1.5L

10L

31L

Dimension Internal

(W

×

D

×

H)

115x115x115mm

215x215x215mm

315x315x315mm

4.53x4.53x4.53''

8.46x8.46x8.46''

12.40x12.40x12.40''

Dimension External

(W

×

D

×

H)

530x490x730 mm

630x590x830mm

730x690x930mm

20.87x19.29x28.74''

24.80x23.23x32.68''

28.74x27.17x36.61''

Material External

Steel Plate with powder heating coated

Heater Element

KANTHAL A-1 (Ceramic heating)

Insulation

Ceramic Board & Wool (Ceramic fiber)

Electrical Requirements

120V, 50/60Hz, 1Φ

9.2 A

N/A

N/A

Cat. No.

FU3MG120

Electrical Requirements

230V, 50/60Hz, 1Φ

4.8A

13.03A

26.1 A

Cat. No.

FU1.5MGV230

FU10MGV230

FU131MGV230

Electrical Requirements

230V, 50/60Hz, 3Φ

N/A

N/A

15.1 A

Cat. No.

FU131MGV230-3

Electrical Requirements

380V, 50/60Hz, 3Φ

N/A

N/A

9.1 A

Cat. No.

FU131MGV380-3

1200

°

C Muffle Furnace with Vacuum

Summary of Contents for SH-FU-1.5MGV

Page 20: ......