BK-T680 User’s Manual

22

5 Routine maintenance

Caution:

Before starting routine maintenance for the printer, make sure the power is turned off.

Do not touch the surface of print head with hands or metal. Do not use forceps so as to prevent print

head, platen roller and sensors being scratched.

Do not use organic solvent like gasoline, acetone and etc.

When cleaning print head or sensors, please wait for pure alcohol to evaporate totally before

starting printing.

It is recommended to do routine maintenance per month.

5.1 Cleaning mark sensor

When the following cases occur, the mark sensor should be cleaned:

The printer doesn’t identify marks correctly.

Steps for cleaning mark sensor:

1)

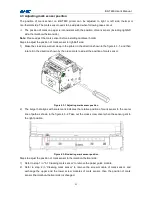

Slightly nip the latches on both sides of paper guide cover and pull outward the top of paper guide

cover to remove the paper guide module.

Figure 5.1-1 Cleaning mark sensor

Caution:

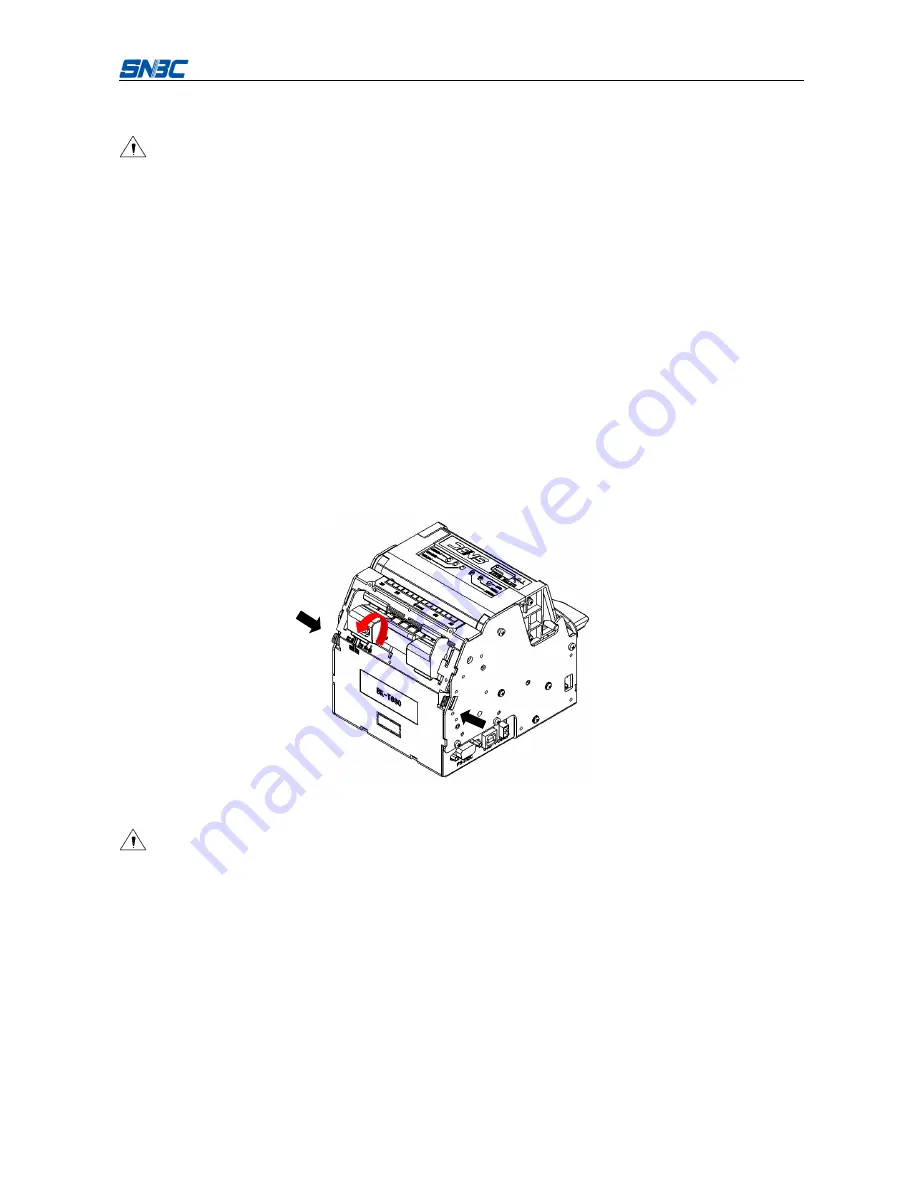

The cable of sensor on paper guide module is connected with main control board, thus do not

remove the paper guide module by force. Pull out the cable of sensor from the main control board

after slowly opening the paper guide module as the above method.

2)

Remove the thumb wheel as shown in figure 5.1-2, and then remove the screw where the mark

sensor is installed (refer to figure 5.1-2) and wipe off the dust or stains on the sensor surface with

soft cotton cloth dipped with pure alcohol (it should be wrung out). Wait for 5 to 10 minutes until

pure alcohol evaporates completely, and then assemble it in the reverse steps. Check the cable

connection after completing the assembly, and turn on the power if the cable is correctly

connected.