5/6

WIRE ROPE REPLACEMENT

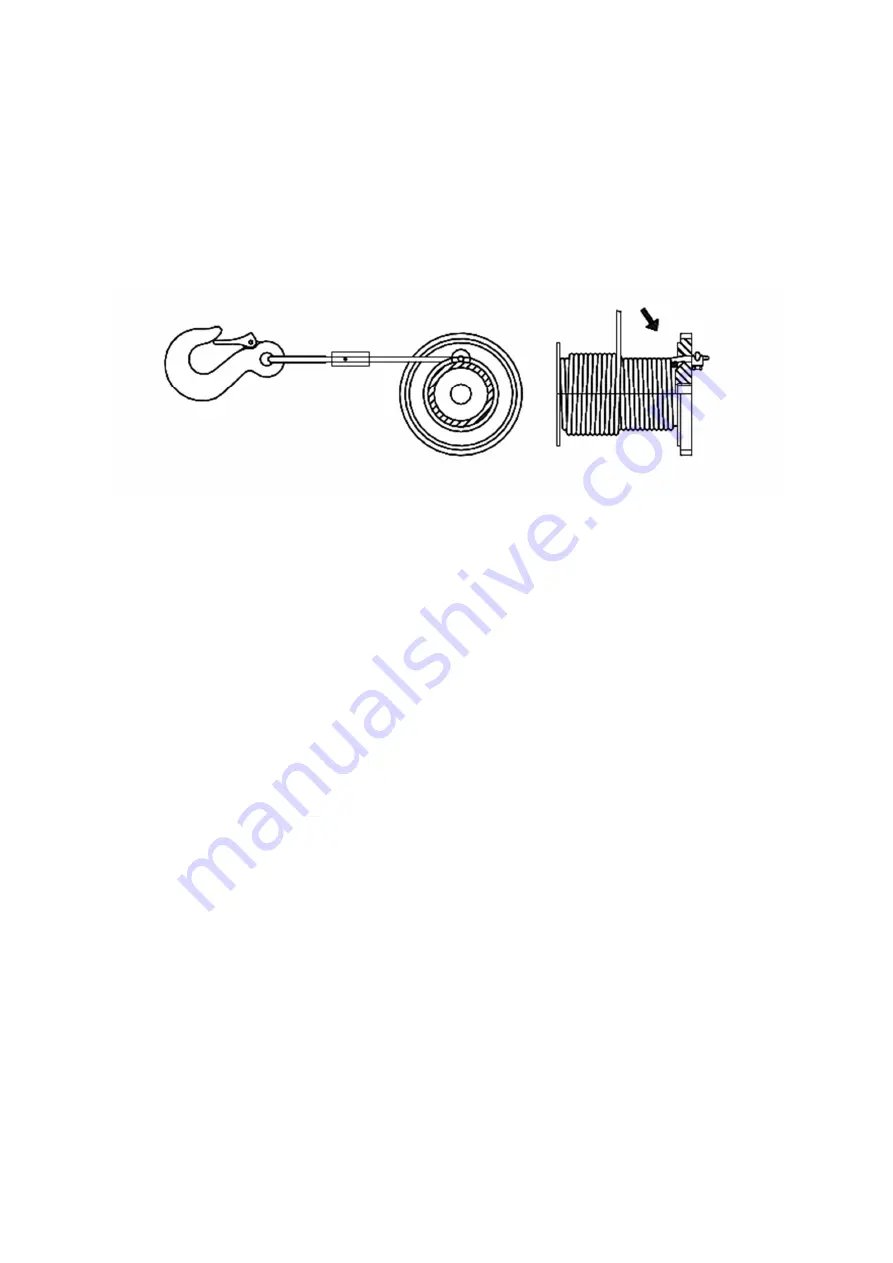

Reel out the old rope from the drum, loosen the rope clamp and remove the old rope.

Run end of a new rope through the hole in the drum face and attach rope clamp to the new

rope.

Leave first thread groove free and start to wind up the rope from the second thread groove.

By turning the handle then wind up the wire rope onto the drum so that the rope is reeled

from above the drum.

! WARNING

ALWAYS wind new wire rope only in above described way. Every other way of rope

winding can cause malfunction of the brake or ratchet pawl (!), eventually higher stress to

the winch mounting fixtures and anchoring structure.

ALWAYS reel a new rope with a preload, tightly pack each coil. Slacked and criss-crossed

rope can cause considerably lower rope life.

GENERAL MAINTENANCE INSTRUCTIONS

Following instructions give you general important information on winch disassembly,

service, check, repair and assembly. Whether the winch was dismounted from any reason,

follow the instructions below:

1. ALWAYS

perform winch service in a clean area.

2. ALWAYS

maintain your workplace clean and free of foreign particles that could get into

the bearings and other movable parts.

3. ALWAYS

use suitable inserts to protect the parts surface, if you are going to squeeze parts

in a vice.

4. NEVER

disassemble the winch more than is necessary to provide required repair.

5. NEVER

use excessive force when dismantling parts.

6. NEVER

use heat or fire when dismantling parts, if those parts will be used again.