13VT-K100/150

13VT-CK10

34

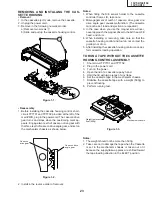

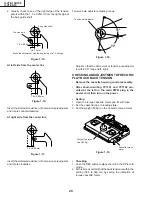

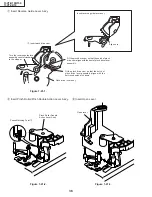

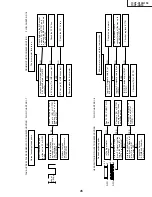

REPLACEMENT OF THE CAPSTAN D.D.

(DIRECT DRIVE) MOTOR

• Remove the mechanism from the main PWB (refer to

Page10 "DISASSEMBLY AND REASSEMBLY" Re-

move the cassette housing Assembly.

• Removal (Follow the order of indicated numbers.)

1. Remove the reel belt

1

.

Figure 1-37.

2. Remove the three screws

2

.

• Reassembly

1. Taking care so that the capstan shaft does not contact

the mechanism chassis, set its position on the mecha-

nism chassis, and then install with the three screws.

2. Install the reel belt.

Notes:

1. After installing the capstan D.D. motor, be sure to

rotate the capstan D.D. motor and check the move-

ment.

2. Set the tape, and check for the tape crease near the

reverse guide in the playback mode. Adjust the A/C

head and azimuth as stated in Page 32 item 2. If

crease is found, adjust as stated in Page 31 "HEIGHT

ADJUSTMENT OF REVERSE GUIDE".

Capstan D.D.

motor

Capstan D.D. motor

control PWB

2

1

Reel belt

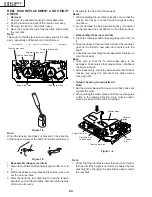

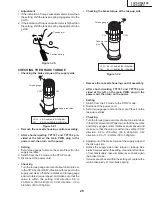

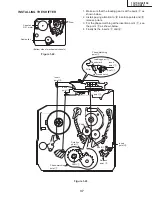

REPLACEMENT OF DRUM D.D. MOTOR

1. Set the eject mode.

2. Withdraw the main power plug from the socket.

• Removal (Perform in numerical order.)

1. Disconnect the FFC cable

1

.

2. Unscrew the D.D. stator assembly fixing screws

2

.

3. Take out the D.D. stator assembly

3

.

4. Unscrew the D.D. rotor assembly fixing screws

4

.

5. Take out the D.D. rotor assembly

5

.

Notes:

1. In removing the D.D. stator assembly, part of the drum

earth spring pops out of the pre-load collar.

Be careful not to lose it.

2. Install, so that the D.D. rotor ass'y and upper drum

ass'y mounting direction check holes align.

(Align the upper drum dent with the rotor hole.)

3. Be careful not to damage the upper drum or the video

head.

4. Protect the hole elements from shock due to contact

with D.D. stator or D.D. rotor ass'y.

5. After installation adjust the playback switching point

for adjustment of servo circuit.

Figure 1-38.

2

4

3

4

5

1

D.D. stator ass'y

D.D. rotor ass'y

FFC

Upper drum