Ref. No.

Part No.

★

Description

Code

Ref. No.

Part No.

★

Description

Code

101

13VT-N100

13VT-N150

13VT-CN10

6

5

4

3

2

1

A

B

C

D

E

F

G

H

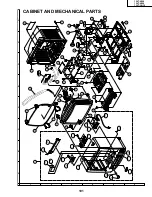

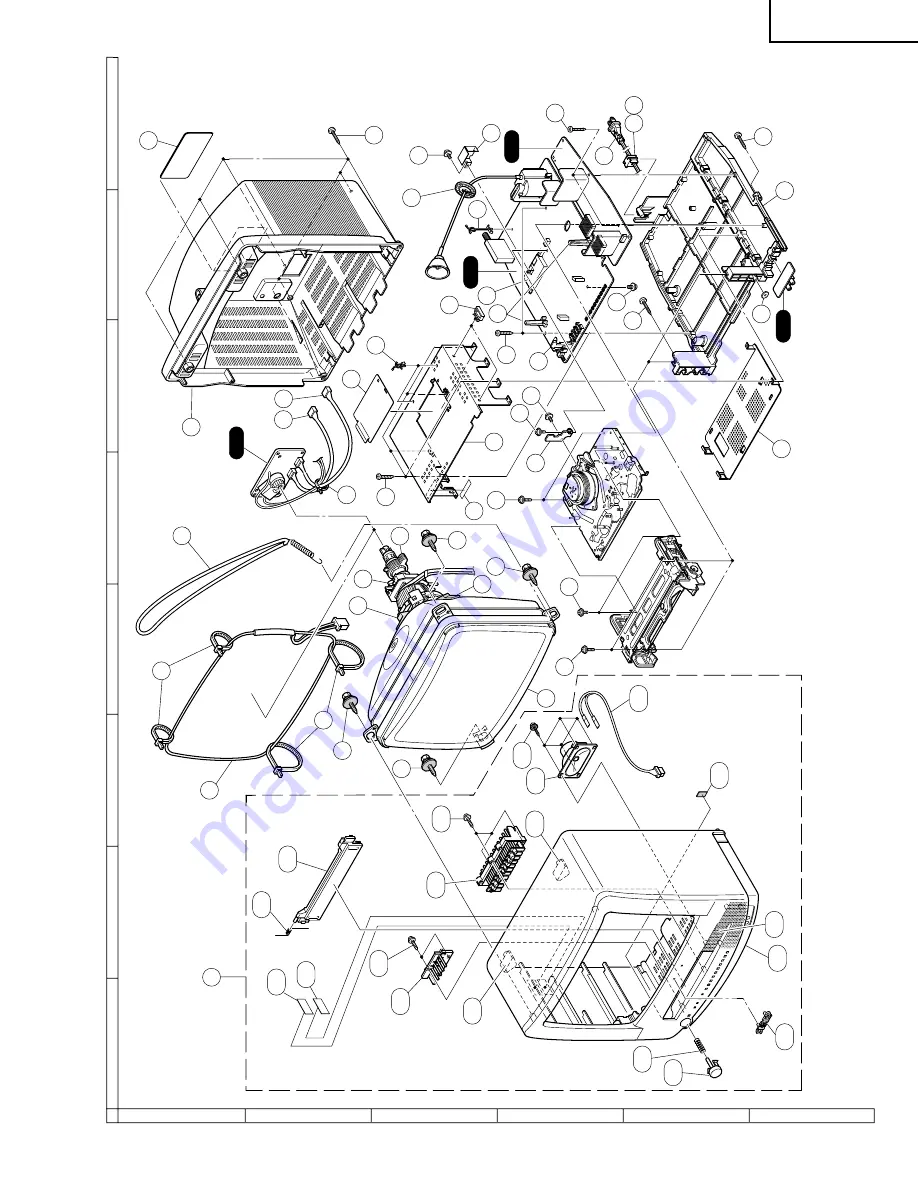

CABINET AND MECHANICAL PARTS

1-10

1-12

1-6

1-3

1-1

30

1-9

1-2

24

28

15

11

13

24

3

25

40

7

26

20

22

9

22

44

33

6

10

16

1

1-11

1-13

1-14

1-4

1-9

22

32

21

27

8

31

20

28

17

34

24

2

23

26

PWB-D

PWB-A

19

22

16

25

25

42

43

1-8

1-8

1-5

38

39

PWB-C

26

24

1-7

1-17

1-15

1-16

41

36

35

PWB-B

Summary of Contents for 13VT-CN10

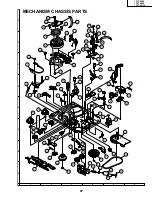

Page 69: ...83 6 5 4 3 2 1 A B C D E F G H 13VT N100 13VT N150 13VT CN10 PWB C POWER Unit Wiring Side ...

Page 70: ...84 6 5 4 3 2 1 A B C D E F G H 13VT N100 13VT N150 13VT CN10 PWB A MAIN Unit Wiring Side ...

Page 71: ...85 6 5 4 3 2 1 A B C D E F G H 13VT N100 13VT N150 13VT CN10 PWB A MAIN Unit Chip Parts Side ...