4

28JW-74H

IMPORTANT SERVICING NOTES

Only qualified service personnel are allowed to carry out maintenance and repair of this receiver.

Servicing of High Voltage System and CRT

It is important that the static charge is removed from the high voltage system when carrying out work on the

receiver. This can be achieved by connecting a 10K resistor (with a suitably insulated lead) from the CRT

cavity connector to the CRT ground tag. This must be carried out with the AC supply disconnected from the

receiver.

Note the following:

•

The CRT in this receiver employs Integral Implosion Protection.

•

If the CRT has to be changed it MUST be replaced with the correct type for continued safe working.

•

DO NOT lift the CRT by its neck.

•

When handing the CRT, ensure that shatterproof goggles are worn.

•

Ensure that the CRT is discharge before handling.

X-Ray

This receiver is designed to keep any x-ray emission to an absolute minimum. Some fault conditions and

servicing procedures may produce potentially hazardous x-ray radiation levels. This is a problem when in

close proximity to the receiver for long periods of time. To reduce any risks associated with this, please

observe the following precautions:

1. When undertaking any servicing on this chassis, DO NOT increase the EHT to more than 32.0 KV, (at a

instantaneous beam current of 1500

µ

A

)

.

2. Ensure that during normal operation the EHT does not exceed 29.5KV±1.5KV (at a beam current of

1650

µ

A). This level has been preset in the factory. Always check that this level has not been exceeded

after carrying out any repair on the receiver.

3. DO NOT replace the CRT with any other type than that specified in the parts listing as this may cause

excessive x-ray radiation.

Before returning the receiver to the customer

In addition to the above checks, the following should also be carried out before returning the receiver to the

customer.

1. Inspect all the leads to ensure that they are dressed correctly and that they are not obstructed or pinched

by any other parts.

2. Ensure that all protective devices are in good condition. These will include nonmetallic control knobs,

insulating fish papers, cabinets backs, compartment covers or shields, mechanical insulators, etc.

Summary of Contents for 28JW-74H

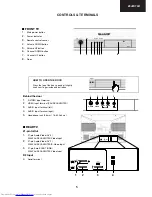

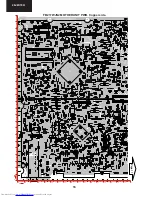

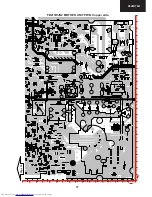

Page 19: ...19 28JW 74H CHASSIS LAYOUT PWB A Mother Unit FB217N2 ...

Page 39: ...39 28JW 74H SCHEMATIC DIAGRAM OF CRT UNIT FB218N2 1 I H G F E D C B A 2 3 4 5 6 7 ...

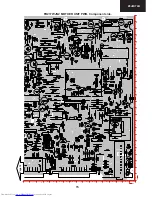

Page 40: ...40 28JW 74H SCHEMATIC DIAGRAM OF MAIN 1 FB217N2 1 I H G F E D C B A 2 3 4 5 6 7 Page 41 ...

Page 41: ...41 28JW 74H 8 9 10 11 12 13 14 I H G F E D C B A Page 40 SCHEMATIC DIAGRAM OF MAIN 1 FB217N2 ...

Page 42: ...42 28JW 74H SCHEMATIC DIAGRAM OF MAIN 2 FB217N2 1 I H G F E D C B A 2 3 4 5 6 7 Page 43 ...

Page 43: ...43 28JW 74H 8 9 10 11 12 13 14 I H G F E D C B A Page 42 SCHEMATIC DIAGRAM OF MAIN 2 FB217N2 ...

Page 44: ...44 28JW 74H SCHEMATIC DIAGRAM OF MAIN 3 FB217N2 1 I H G F E D C B A 2 3 4 5 6 7 Page 45 ...

Page 45: ...45 28JW 74H 8 9 10 11 12 13 14 I H G F E D C B A Page 44 SCHEMATIC DIAGRAM OF MAIN 3 FB217N2 ...

Page 46: ...46 28JW 74H SCHEMATIC DIAGRAM OF MAIN 4 FB217N2 1 I H G F E D C B A 2 3 4 5 6 7 Page 47 ...

Page 47: ...47 28JW 74H 8 9 10 11 12 13 14 I H G F E D C B A Page 46 SCHEMATIC DIAGRAM OF MAIN 4 FB217N2 ...

Page 48: ...48 28JW 74H SCHEMATIC DIAGRAM OF CONTROL UNIT FB219N1 1 I H G F E D C B A 2 3 4 5 ...

Page 49: ...49 28JW 74H 01 2 01 01 2 2 3 4 3 3 5 3 67 3 2 01 3 4 8 98 3 4 2 01 6 7 TROUBLESHOOTING TABLES ...

Page 51: ...51 28JW 74H 4 4 4 4 3 3 C 4 3 4 D 4 3 4 3 3 4 ...

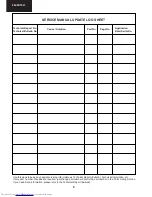

Page 62: ...62 28JW 74H Notes ...

Page 63: ...63 28JW 74H Notes ...