AY/AE-A079E

AY/AE-A099E

26

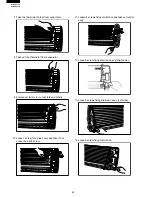

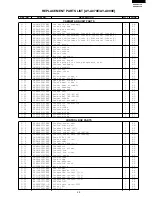

7.Take the thermistor holder from evaporator.

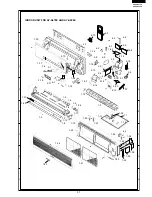

11.Loosen 4 screws fixing control box and take out control

ass'y.

8.Take out the thermistor from evaporator.

9.Disconnect fan motor connectors and others.

10.Loose 1 screw for a pipe cover and take it out.

Loose the earth screw.

12.Loose a screw fixing drain pan ass'y.(Right side)

13.Loose 2 screws fixing drain pan ass'y.(Left side)

14.Loose a screw fixing drain hose.