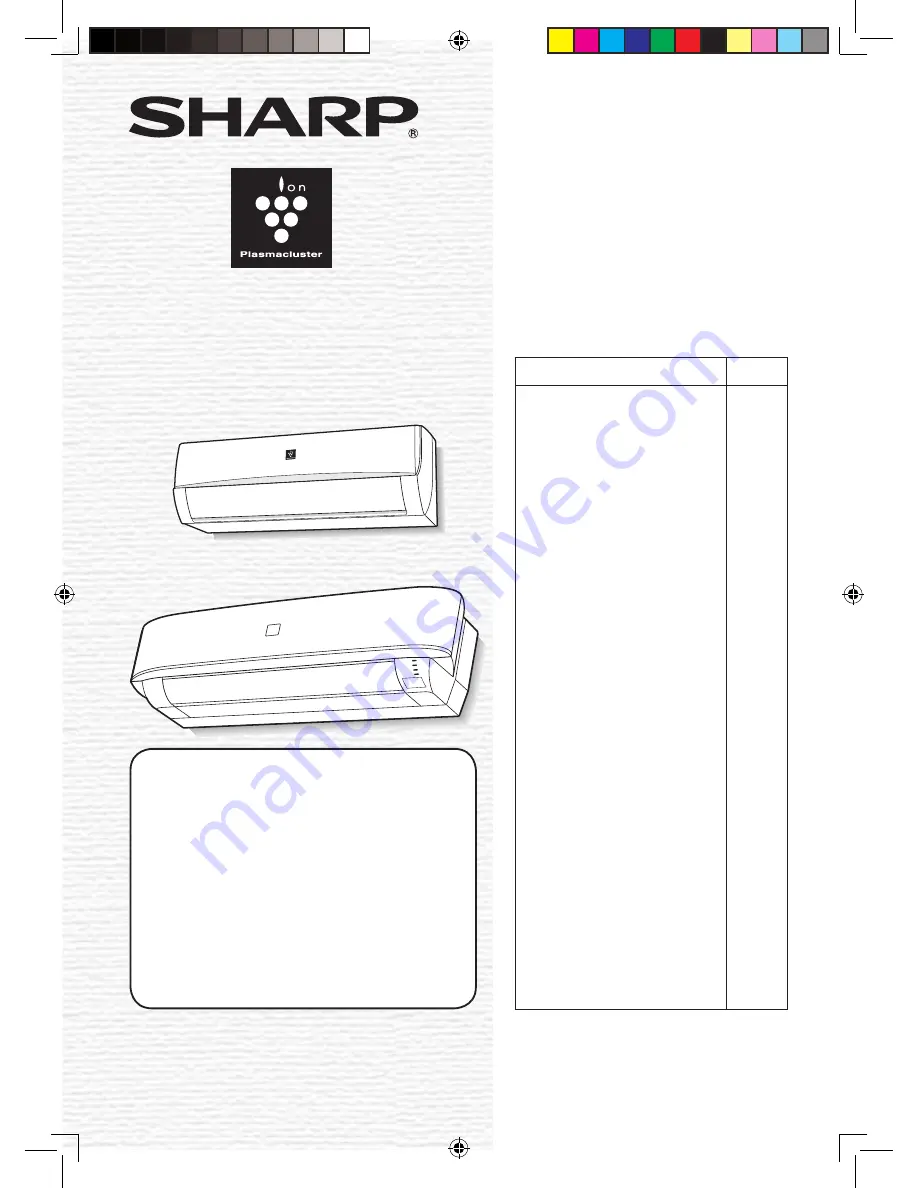

OPERATION MANUAL

INDOOR UNIT OUTDOOR UNIT

AH-PN10 AU-PN10

AH-PN10-GY AU-PN10

AH-PN13 AU-PN13

AH-PN13-GY AU-PN13

AH-PN19 AU-PN19

AH-PN24 AU-PN24

AH-L10 AU-L10

AH-L13 AU-L13

CONTENTS

Page

IMPORTANT SAFETY

INSTRUCTIONS

1

PART NAMES

2

USING THE REMOTE

CONTROL

5

AUXILIARY MODE

5

TIPS ON SAVING

ENERGY

5

BASIC OPERATION

6

ADJUSTING THE AIR

FLOW DIRECTION

7

POWERFUL JET

OPERATION

7

GENTLE COOL AIR

8

PLASMACLUSTER

OPERATION

8

TIMER OPERATION

9

ONE-HOUR OFF TIMER

10

DISPLAY BUTTON

10

MAINTENANCE

11

OPERATING CONDITION

11

BEFORE CALLING FOR

SERVICE

12

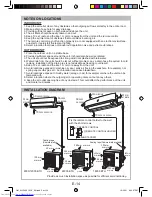

INSTALLATION MANUAL

13

AH-PN10, 10GY AH-L10

AH-PN13, 13GY AH-L13

AH-PN19, AH-PN24

INSTALLATION MANUAL

Thank you for purchasing a SHARP air conditioner.

Please read this manual carefully before operating

the product

OM_AH-PN10 13GY_EN.indd 1

OM_AH-PN10 13GY_EN.indd 1

12/22/11 6:30:07 PM

12/22/11 6:30:07 PM