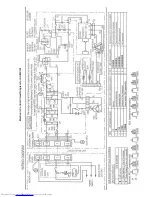

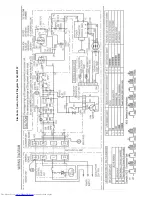

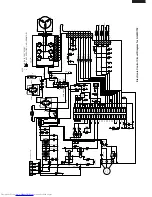

MICROCOMPUTER CONTROL SYSTEM

Electronic Control Circuit Diagram for AH-

MX122

and

AH-MX152

(CN9)

LED101

LED104

LED103

LED102

LED110

LED109

LED108

LED107

LED106

LED105

R101

R102

R103

R104

R105

R106

R107

R108

R109

1/2W

1/2W

1/2W

1/2W

220

220

300

220

220

220

220

220

100

1/2W

1/2W

1/2W

1/2W

1/2W

LED111

1/2W

1/2W

1/2W

330

R114

R40

3.3K

50V

50V

C21

C22

1000p

1000p

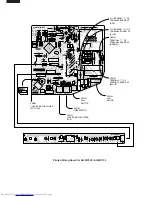

BCN3

BCN2

R58~R62

(SW2)

MOTOR

FAN

IC

HOLE

3

2

1

P00

P01

P02

P03

P04

P05

P06

P07

P10

P11

P12

P13

P14

P16

P17

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

52

53

54

55

56

57

58

59

60

61

62

63

64

P63

P64

P65

P66

P67

AVss

Vref

Vcc

P30

P31

P32

P33

P34

51

50

49

P35

P36

P20

P21

P22

32

31

30

P23

P24

P25

P26

P27

Vss

Xout

Xin

P40

P41

RESET

CNVss(Vpp)

P42

29

28

27

26

25

24

23

22

21

20

19

18

17

P62

P61

P60

P57

P56

P55

P54

P53

P52

P51

P50

P45

P43

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

NC

M3803**

IC1

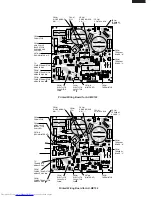

(PATTERN SIDE)

PC2

PC1

4

2

4

3

1

2

4.7K

100K

+

0.047

µ

50V

250V

0.01

µ

680

680

2W

2W

680

680

2W

2W

680

2W

22K

P15

1

10K

10K

0.1

µ

25V

8M

6

5

4

3

2

1

PIPE TEMP.

TH2

10k

Ω

(25˚C)

15k

Ω

(25˚C)

ROOM TEMP.

TH1

C2

0.22

µ

250V

NR1

IN

T

250V

OUTRY1

WPE

N

N

2S

1

UNIT

OUTDOOR

TO

TERMINAL

BOARD

KID65783AP

IC6

10

SW1

5V

GND

12V

-24V

33K

33K

33K

33K

33K

16V

C26

0.01

µ

R41

1.8K

33K

33K

33K

1000P

3

2

3

1

2

R23

3.3K

CN6

100

µ

C8

10V

+

FAN L

FAN M

FAN H

RATE HEAT

TEA

MODEL 5

MODEL 4

MODEL 3

MODEL 2

MADEL 1

R42

R43

R44

R45

R46

R47

R48

R49

R50

R51

R52

R53

R54

R55

R56

JP 1

JP 2

JP 3

JP 4

JP 5

R67

R66

12K

12K

2W

D9

D8

R65

R64

11K

2W

2W

11K

2W

C30

100

µ

35V

C29

ZD1

R63

C28

D7

R57

C27

R38

R37

R36

R35

R34

JP8

JP7

JP6

R30

380

R29

680

C19

+

+

C18

10

µ

16V

16V

10

µ

10K

(F)

R27

10K

(F)

R26

R21

R20

R19

C13

C12

C11

IC7

IC8

OSC1

FRONT

1/2W

R9

R8

C9

C10

1000p

50V

25V

0.1

µ

R5

RY1

R4

BZ1

BUSY

1

12V

2

5V

3

4

CLOCK

5

SERIAL

OE

6

7

RESET

GND

8

HOT KEEP

PREHEAT

WIRELESS

2.7K

50V

1000p

1000p

50V

P37

P44

P46

P47

4

3

2

1

7

6

5

8

1

1K

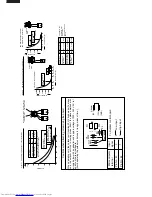

FUSE

THERMAL

SSR1

470

1.8K

16

9

10K

3

1

POWER

SUPPLY

SINGLE

PHASE

2

1

JP10

33K

R2

TRANS1

D1~4

33K

R3

+

C4

50V

0.1

µ

7812

IC2

35V

C3

1000

µ

IN

0.1

µ

25V

OUT

C5

+

47

µ

25V

100

1/2W

R1

JP11

+

C6

25V

47

µ

0.1

µ

25V

C7

IN

IC3

D5

7805

25V

0.1

µ

R31

IC4

8

NC

9

11

8

13

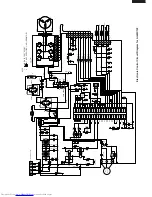

11

C31

250V

0.01

µ

SSR1

CNR1

L1

430V

C1

2

µ

FUSE

THERMAL

MOTOR

FAN

5

3

1

CN1

C32

C33

680

R6

CN101

22

3

3

1

1

8

8

1

1

22

3

3

44

5

5

66

7

7

CN102

NC

NC

10(B2)

11(A2)

12(F2)

15(B1)

18(F1)

17(G1)

16(A1)

14(CM1)

13(CM2)

9(H2)

8(C2)

7(G2)

6(D2)

5(E2)

4(H1)

3(C1)

2(D1)

1(E1)

H2

H1

CM1,2

D2

G2

A2

E2

F2

B2

C2

D1

G1

A1

C1

B1

E1

F1

33K

33K

R33

R32

JP9

JP99

TEST

POWE ON

R39

20K

C24

16V

0.01

µ

1

3

2

C25

50V

1000P

330

W115

1/2W

LED121

R116

330

1/2W

1/2W

R111

330

R112

R110

330

330

1/2W

R113

330

25V 0.1

µ

680

680

Q1

Q2

R68

R69

3A

33K

CN7

0.1

µ

25V

33

µ

10V

+

5V

GND

C201

C202

IC201

BCN201

BCN1

11

33

2

2

6.8K

8

IC5

9

1

16

10K

R7

CN3

1

2

3

4

5

LOUVER

MOTOR

UPPER

LOWER

LOUVER

MOTOR

4

5

1

CN2

2

3

∆

:TEST POINT

(NOTE)

LED101 : OPERATION

LED102 : TIMER

LED103 : ROOM TEMP.

LED104 : OUTDOOR TEMP.

SW1 : AUX.(TEST RUN)

SW2 : POWER SELECTION

LED105 : POWER MONITOR ECO

LED106 : POWER MONITOR 1

LED107 : POWER MONITOR 2

LED108 : POWER MONITOR 3

LED109 : POWER MONITOR 4

LED110 : POWER MONITOR POWER

HL

50V

C34

JP34

C17

16V

0.01

µ

JP23

680

NONE

USE

SW2

USE

NONE

NONE

NONE

NONE

NONE

USE

15K

13K

13K

15K

15K

13K

13K

15K

13K

NONE

NONE

USE

NONE

NONE

NONE

NONE

USE

USE

NONE

NONE

NONE

NONE

USE

NONE

NONE

13K

15K

13K

13K

15K

15K

13K

13K

15K

USE

NONE

NONE

NONE

NONE

USE

USE

15K

13K

13K

15K

15K

13K

13K

15K

13K

NONE

NONE

USE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

USE

USE

NONE

NONE

NONE

13K

24K

15K

13K

13K

15K

15K

13K

13K

130K

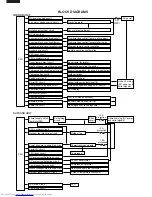

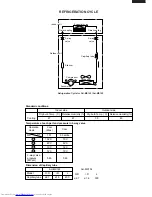

AH-

MX122

AH-

MX152

AH-X10BE

AY-X08BE

A

H

-

MX152

A

H-MX122

MODEL

JP1

JP2

JP3

JP4

JP5

JP6

JP7

JP8

JP9

R51

R50

R49

R48

R47

R46

R45

R44

R43

R42

JP99

68

K

13K

13K

15K

15K

13K

13K

----

47

K

13K

NONE

USE

USE NONE USE NONE

NONE

USE

NONE

NON

E

33

K

13K

13K

2.4

K

3.6

K

13K

----

- 1

5K

15K

13K

USE

NONE

USE NONE

USE

NONE

NONE

NONE