7

AH-S22AW2

AH-S25AW2

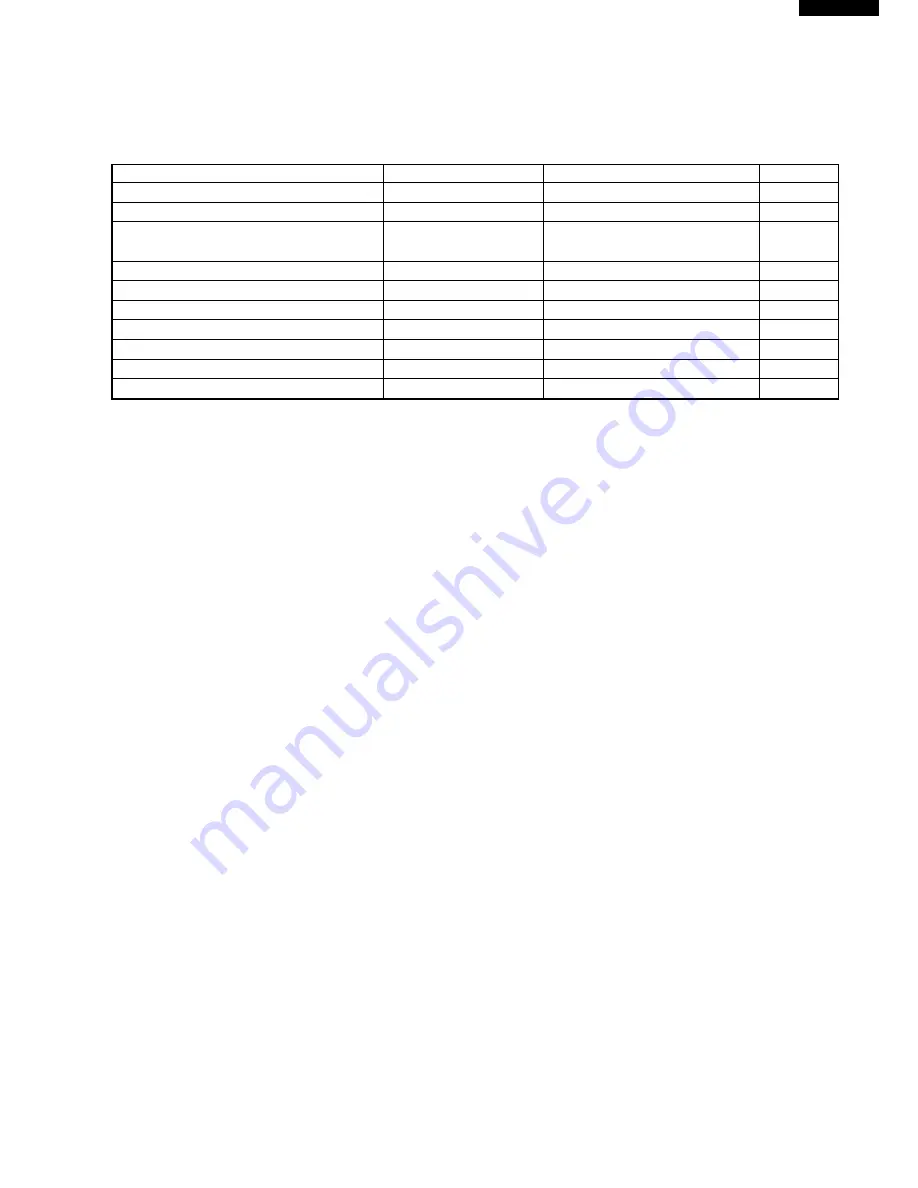

For Model AH-S22AW2, AH-S25AW2, AU-S22AW2 and AU-S25AW2

DESCRIPTION

MODEL

REMARKS

SITE

Indoor fan motor

MLA486

220 - 240V, 50Hz 220V, 60Hz

AH

Indoor fan motor capacitor

–

430V, 1.5

µ

F

AH

Transformer

–

Primary; AC 230V, 50Hz

AH

Secondary; AC14.6V, 50Hz

Fuse

–

250V, 2.5A

AH

Compressor

2RD110N5BA03

3-PHASE Induction motor

AU

Outdoor fan motor

MLA485

220 - 240V, 50/60Hz

AU

Outdoor fan motor capacitor

–

430V, 1.5

µ

F

AU

WPE1

–

QFS-AA047JBE0(13A, 250V)

AU

WPE2

–

QFS-GA015JBE0(10A, 250V)

AU

WPE3

–

QFS-GA008JBE0(3A, 250V)

AU

ELECTRICAL PARTS