AL-1651CS ADJUSTMENTS 9 - 2

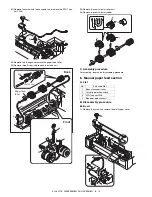

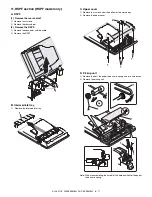

2) Set the copy magnification ratio to 100%.

3) Make a copy on A4 or 81/2" x 11" paper.

4) Measure the length of the copied scale image.

5) Calculate the sub scanning direction copy magnification ratio

using the formula below.

6) Check that the actual copy magnification ratio is within the

specified range. (100 ± 1.0%).

If it is not within the specified range, perform the following

procedures.

7) Execute TC 48-01 to select the sub scanning direction copy

magnification ratio adjustment mode.

To select the adjustment mode, use the [

←

/

→

] key. (SCAN mode

lamp ON)

8) Enter the new set value of sub scanning direction copy

magnification ratio with the copy quantity set key, and press the

[START] key.

Repeat procedures 1) - 8) until the sub scanning direction actual copy

magnification ratio in 100% copying is within the specified range.

When the set value is changed by 1, the magnification ration is

changed by 0.1%.

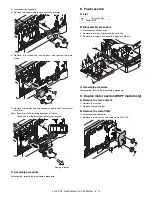

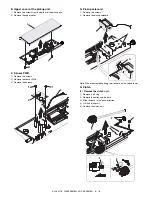

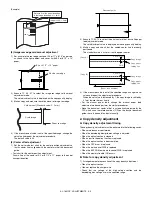

B. Image position adjustment

The employed test commands and the contents are as follows:

The modes can be selected by pressing [

←

/

→

] key.

(*): Support for the installation models. For non-installation models,

skip.

* In the 2nd print center offset adjustment, print is made forcibly as

1to2/Long Edge from OC regardless of duplex setting.

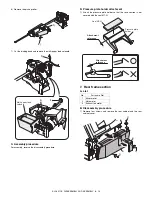

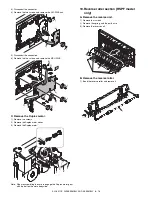

(1) Lead edge adjustment

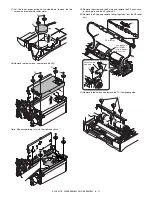

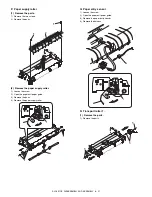

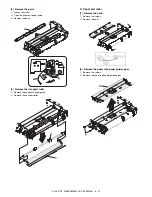

1) Set a scale to the center of the paper lead edge guide as shown

below, and cover it with B4 or 8 1/2" x 14" paper.

2) Execute TC 50 - 01

3) Set the print start position (A: COPY mode lamp ON), the lead

edge void amount (B: PRINT mode lamp ON), the scan start posi-

tion (C: SCAN mode lamp) to zero, and make a copy of the scale

at 100%.

4) Measure the image loss (Rmm) of the scale.

Set C = 10 x R (mm). (Example: Set to 40.)

When the value of C is increased by 10, the image loss is

decreased by 1mm. (Default: 50)

5) Measure the distance (Hmm) from the paper lead edge to the

image print start position.

Set A = 10 x H (mm). (Example: Set to 50.)

When the value of A is increased by 10, the image lead edge is

moved to the paper lead edge by 1mm. (Default: 50).

6) Set the lead edge void amount to B = 50 (2.5mm). (Default: 50)

When the value of B is increased by 10, the void is extended by

about 0.1mm. (For 25 or less, however, the void amount is

regarded as 0.)

* The SFP adjustment is made by adjusting the SPF image scan start

position after OC adjustment.

=

Copy image dimensions

X 100 (%)

Original dimension

Mode

Display

item

Default

LED

TC

Print start position

(Main cassette paper

feed)

TRAY1

50

COPY mode lamp

Main cassette

lamp

50-01

(*) Print start position

(2nd cassette paper

feed)

TRAY2

50

COPY mode lamp

2nd cassette lamp

Print start position

(Manual paper feed)

MFT

50

COPY mode lamp

Manual feed lamp

Image lead edge void

amount

DEN-A

50

PRINT mode lamp

Image scan start

position

RRC-A

50

SCAN mode lamp

Image rear edge void

amount

DEN-B

50

COPY mode lamp

PRINT mode lamp

SCAN mode lamp

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDDENCD

STAINLESS

Shizuoka

100

110

120

130

150

140

mm

1/2mm

JAPAN

HARDDENCD

STAINLESS

Shizuoka

110

10

20

10

20

Original (Scale)

Paper feed

direction

Reference

Comparison point

Copy

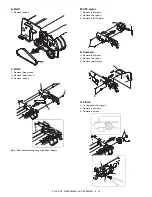

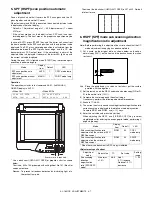

Mode

Display

item

Default

LED

TC

Print center offset

(Main cassette paper

feed)

TRAY1

50

COPY mode lamp

Main cassette lamp

50-10

(*) Print center offset

(2nd cassette paper

feed)

TRAY2

50

COPY mode lamp

2nd cassette lamp

Print center offset

(Manual paper feed)

MFT

50

COPY mode lamp

Manual feed lamp

2nd print center

offset (Main cassette

paper feed)

SIDE2

50

PRINT mode lamp

Main cassette lamp