AL-1651CS ADJUSTMENTS 9 - 5

3. High voltage adjustment

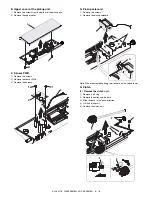

A. Main charger (Grid bias)

Note:

• Use a digital multi meter with internal resistance of 10M

Ω

or more

measurement.

• After adjusting the grid LOW output, adjust the HIGH output. Do not

reverse the sequence.

Procedures

1) Set the digital multi meter range to DC700V.

2) Set the positive side of the test rod to the connector CN11-3

(GRID) of high voltage section of the power PWB and set the

negative side to the frame ground (power frame).

3) Execute TC 8-02. (The main charger output is supplied for 30 sec

in the grid voltage HIGH output mode.)

4) Adjust the control volume (VRG1) so that the output voltage is 580

±12V.

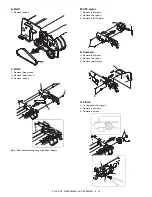

B. DV bias check

Procedures

1) Set the digital multi meter range to DC500V.

2) Set the positive side of the test rod to the connector CN-10-1 (DV

BIAS) and set the negative side to the frame ground (power

frame).

3) Execute TC 25-01 to output the developing bias for 30sec, and

check that the output is –400±8V.

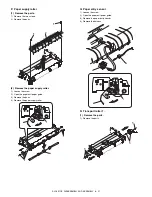

4. Duplex adjustment

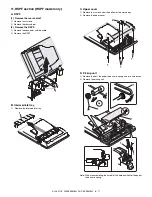

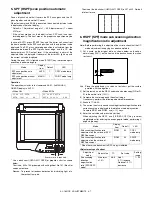

A. Adjusting the paper reverse position in memory

for duplex copying

This step adjusts the front surface printing (odd-number pages of a

document set) in the S-D mode copying and the leading edge position

of an image on even-number pages in the D-S mode.

That is, it covers the adjustment of the second surface printing mode

(image loss at the front edge of an image) in which image data is once

stored in memory.

The image data is read, starting from its front end in the document

delivery direction (Reference direction of document setting in the OC

mode)and stored in memory.

This stored image data is printed starting at the printing start position,

in the order of last-stored data to the first-stored data.

In other words, the front edge image loss of the image can be adjusted

by changing the document read end position.

(Adjustment procedure)

1) Preparing test chart (Draw a scale at the rear end of one side of a

sheet of A4 white paper or letter paper)

2) Set the test chart so that the scale is positioned as shown below, in

the S-D mode and the D-S mode.

3) Execute test command 50-18.

Select the SPF memory reverse output position, and press

[START] key to make a copy.

Adjust the setting so that the front edge image loss is less than 4.0

mm in the R-SPF mode.

An increase of 1 in setting represents an increase of 0.1 mm in

image loss.

Note: • A digital multi meter with internal resistance of 1G

Ω

must be

use for correct check.

• The adjustment volume is locked, and no adjustment can be

made.

VRG1

VRDV

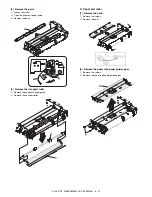

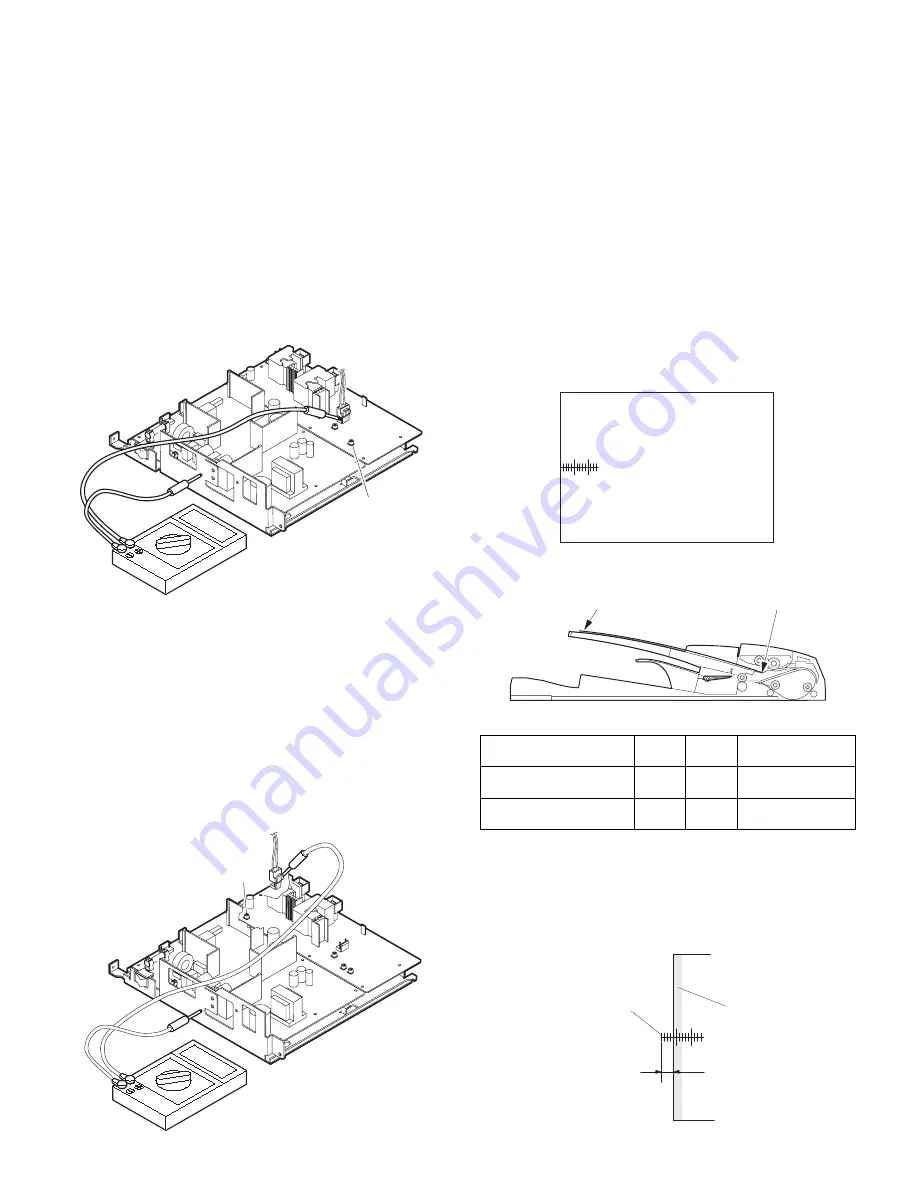

Mode

Display

item

Default

LED

OC memory reverse

output position

OC

50

COPY mode lamp

SPF memory reverse

output position

SPF

50

PRINT mode lamp

5 10

Scale (S-D mode)

Scale (D-S mode)

5 10

The front edge of the

scale on test chart

Front edge of paper

Void area

less than 4 mm