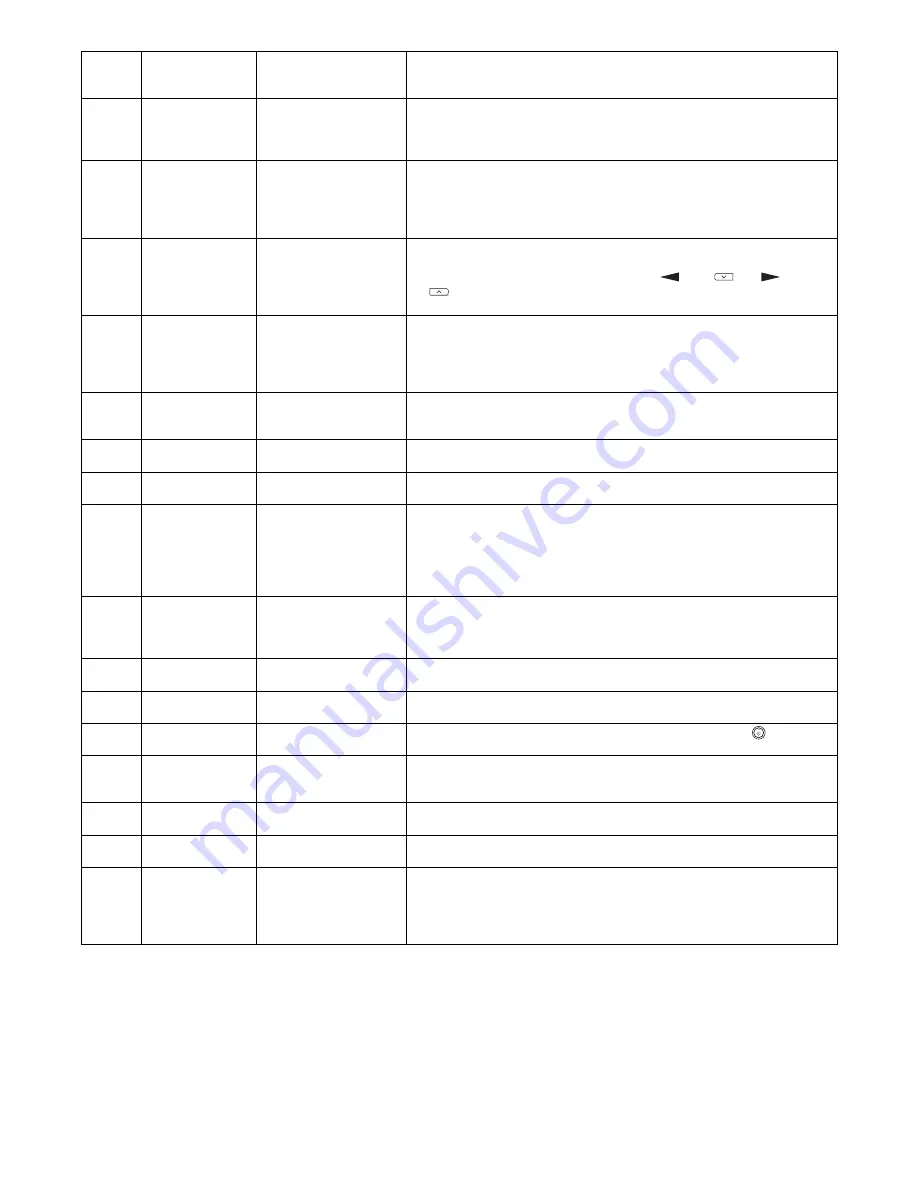

AL-2020/2035/2040/2050/2060 USER PROGRAM 11 - 3

12

MARGIN WIDTH

1: 1/4"

2: 1/2"

3: 3/4"

4: 1"

• Use this setting to set the margin width.

13

MEM. FOR

PRINTER

1: 30%

2: 40%

3: 50%

4: 60%

5: 70%

• Use this to change the proportion of machine memory used for printer mode.

14

AUTO KEY

REPEAT

1: ON

2: OFF

• Use this setting to select whether or not holding down a key causes repeated

input of the key. For keys that normally cause a set value to decrease or

increase when held down (for example, the [

] key (

) or [

] key

(

)), this program can be used to have the set value not change when the

key is held down.

15

KEY PRESS TIME

1: NORMAL

2: 0.5 SEC.

3: 1.0 SEC.

4: 1.5 SEC.

5: 2.0 SEC.

• Use this setting to select how long a key must be pressed for the input to be

accepted.

By selecting a longer time, you can prevent settings from being changed by

the accidental pressing of a key.

16

KEY TOUCH

SOUND

1: LOW

2: HIGH

3: OFF

• This sets the volume of beep signals.

17

SOUND AT

DEFAULT

1: ON

2: OFF

• Use this to sound a beep when a base setting is selected.

18

TONER SAVE

MODE

1: ON

2: OFF

• This mode reduces toner usage by about 10% when copying. Toner save

mode is effective when the exposure mode is AUTO or TEXT.

19

AE LEVEL

ADJUST

1: SPF/RSPF

(Adjustment to

5 levels is possible.)

2: DOCUMENT GLASS

(Adjustment to

5 levels is possible.)

• This is used to adjust the exposure level.

• The automatic exposure level can be adjusted separately for the document

glass and the RSPF.

• For the procedure for adjusting the exposure and guidelines for numeric

values. The factory default setting for the exposure level is center.

20

LANGUAGE

1: AMERICAN ENGLISH

2: ENGLISH

3: FRENCH

4: SPANISH

• This is used to set the language used in the display.

21

RESET FACTORY

1: YES

2: NO

• This is used to return all settings to the factory default settings.

22

SORT AUTO

SELECT

1: ON

2: OFF

• Use this setting to enable or disable sort auto select mode.

24

CHECK RSPF

OPEN

1: ON

2: OFF

• You can set the operation that takes place if the [START] key (

) is pressed

when the RSPF is not completely closed.

25

VALID COPY

WIDTH

1: 8.5x11

2: 5.5x8.5

• Set the allowed paper sizes for copying from the bypass tray. When "5.5x8.5"

is selected, a copy of a letter size original will only be printed up to invoice

size.

28

LSU SETTING

1: ON

2: OFF

• Select whether copying is only allowed when the polygon motor is rotating, or

also when the polygon motor is stopped.

29

PAPER TYPE

1: PLAIN PAPER

2: HEAVY PAPER

• Set the temperature of the fusing unit when the bypass tray is used. Normally

"PLAIN PAPER" should be selected.

30

DISPLAY

CONTRAST

1: LIGHTER

2: LIGHT

3: NORMAL

4: DARK

5: DARKER

• Set the contrast of the display.

Program

number

Program name

Setting codes

(factory default setting

appears in bold)

Explanation

Summary of Contents for AL-2020

Page 217: ...Memo ...