MAINTENANCE

2 - 8

*1 Main blade and fur brush

If defective cleaning occurs due to the adhesion of paper dust, etc., the edge of the blade might have

been damaged. Replace the blade regardless of the number of the copies made so far. Also replace

the fur brush at this time

*2 Recovery blade

If the edge of the blade is damaged, replace the blade regardless of the number of copies made so

far.

*3 Drum separation claw

If the tip of the separation claw has been damaged (e.g. worn coating) or separation claw marks are

apparent in the copied image, replace the claw regardless of the number of copies made so far.

Clean the tip of the claw by lightly wiping with a dry cloth. After cleaning, be sure to remove bits of lint

from the claw. In addition, be sure to apply patting powder (lubricant) to the separation claw after

cleaning the claw and when replacing the claw or drum.

*4 Drum

Refer to section “3.2 Checking and Cleaning the OPC Drum”.

*5 Air filter, Duct filter

Replace the air filter if it is heavily dirty.

*6 Charger wire and case

Use a cloth which should be soaked in water and then wrung lightly to clean those.

*7 Developer material

After replacing the developer material, be sure to adjust the corresponding auto-toner sensor.

*8 Upper and lower heat rollers

Refer to section “3.5 Checking and Cleaning Upper and Lower Heater Rollers”.

*9 Heat roller separation claw

If the tip of the separation claw is chipped, replace it regardless of the number of copies made so far.

If toner adhering to the separation claw is forcibly scraped off, the claw may be damaged. Therefore,

replace the claw if its tip is heavily coated with toner.

*10 Heat roller cleaning roller 1, 2, 3, 4

Refer to section “3.4 Checking and Replacing Heat roller cleaning roller 1, 2, 3, 4”.

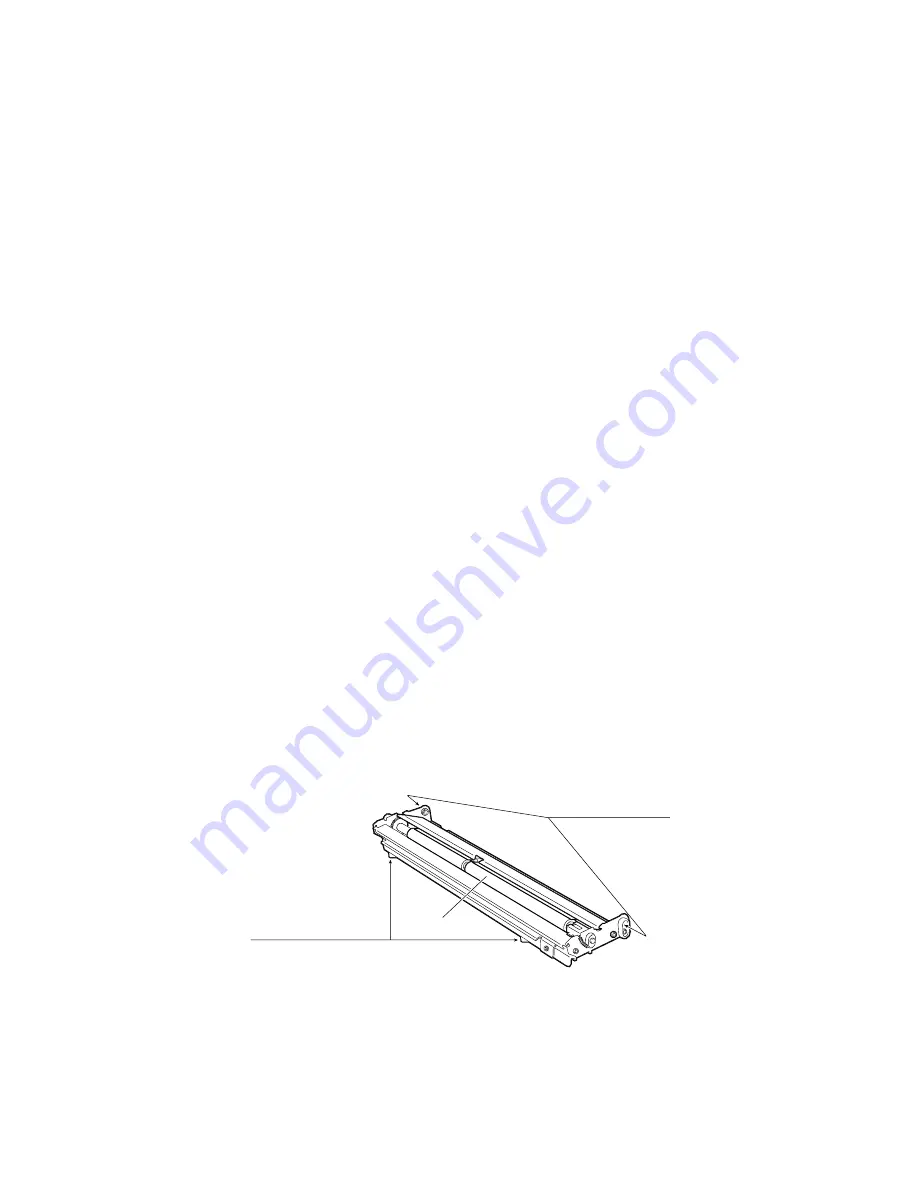

*11 Aligning unit support bush and pressurizing leaf spring

Aligning unit

White Molycoat

on inner surface of bush

* Apply one drop.

White Molycoat on surface

of pressurizing leaf spring

* Apply one drop.

Summary of Contents for AR-650

Page 103: ...MAINTENANCE 2 6 Rear drive system 38 36 37 3 54 54 54 54 54 54 96 12 81 63 63 46 ...

Page 104: ...2 7 MAINTENANCE ADF front sectional view 100 104 109 105 106 102 108 99 101 103 107 98 ...

Page 122: ...SUPPLIES 3 10 13 CONNECT 15 CLOSE 2 1 14 CLOSE 1 2 16 TURN ON 17 PRESS 18 END ...

Page 169: ...Click Finish button then Virtual Modem installation is completed 5 5 ...

Page 179: ...To make the connection ONLINE mode click button before firmware downloading 5 15 ...

Page 194: ......

Page 195: ...MEMO ...

Page 196: ...MEMO ...

Page 197: ...MEMO ...

Page 198: ...MEMO ...

Page 199: ...MEMO ...