: Jan. 9 2004

1

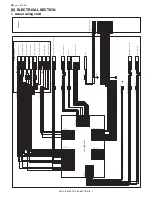

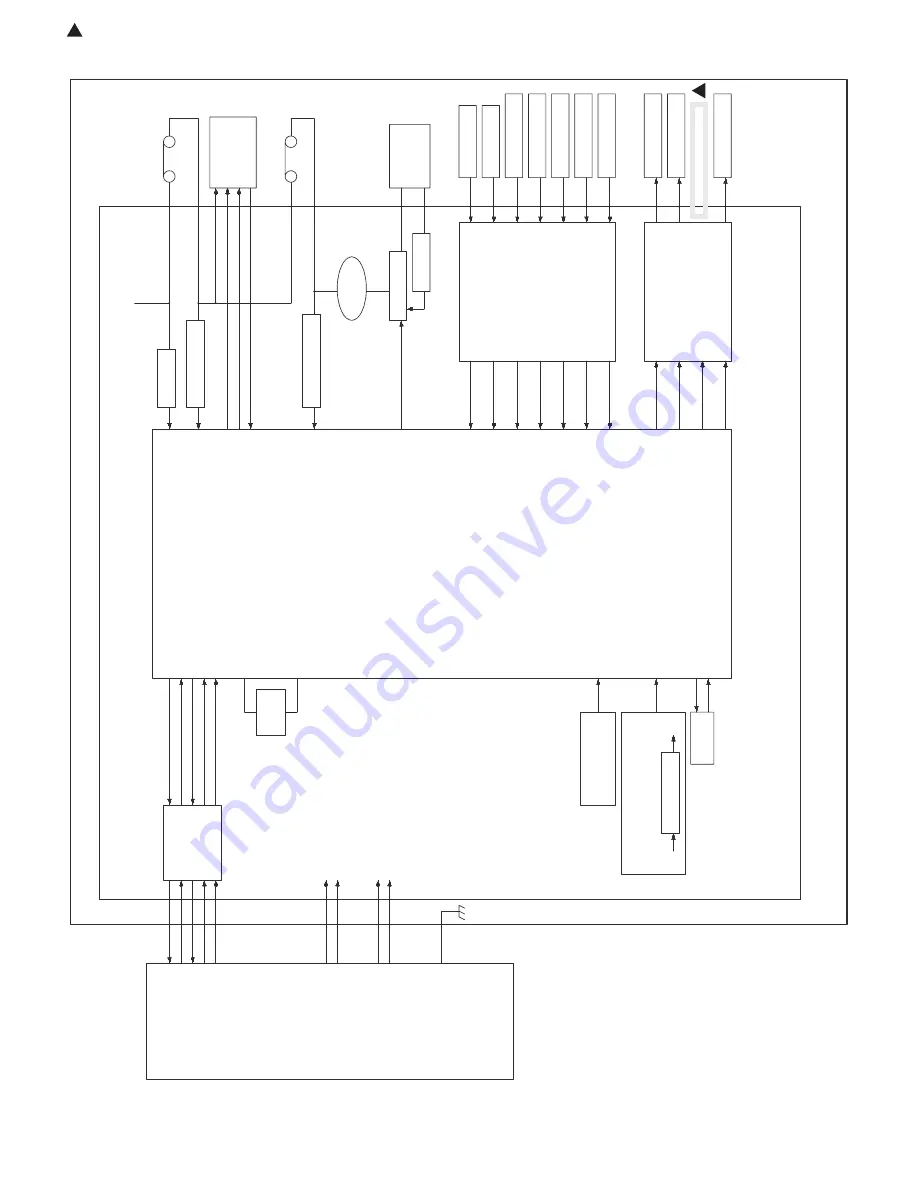

AR-LC6 ELECTRICAL SECTION 8 - 2

2. Block diagram

EEPROM

RXD-LCC

DSR-LCC

TXD-LCC

DTR-LCC

RES-LCC

GND2

5V

24V

GND1

F.G.

Main unit

Comm

unication

b

uff

er circuit

Xtal

7.37MHz

24V monitor

circuit

24V

Upper door open/close

s

w

itch (LOSW)

Upper limit s

witch (LLSW)

Lift motor (LLM)

Upper limit sensor

(LUD)

Lo

w

er limit sensor

(LLD)

P

aper presence/empty

sensor (LPED)

P

a

per e

xit sensor (L

TD)

Main unit connection

sensor (L

T

O

D)

Cassette sensor (LCD)

Remaining quantity

sensor (LRE)

P

aper f

eed clutch

(LPFCL)

T

ranspor

t clutch

(L

TCL)

P

a

per f

e

ed solenoid

(LPSL)

T

ranspor

t motor

(L

TM)

Upper door detection

monitor circuit

Upper limit detection

monitor circuit

P

oly-s

witch 1.1A

Lift motor dr

iv

e

circuit

Current limit

circuit

Sensor input circuit

Solenoid/clutch dr

iv

e circuit

CPU (HD64F3644H)

Ar

ithmetic section

On-board wr

ite circuit

P

o

w

er 12V circuit

Comm

unication wr

ite circuit

24V

12V

LCC MAIN PWB

LCC

1