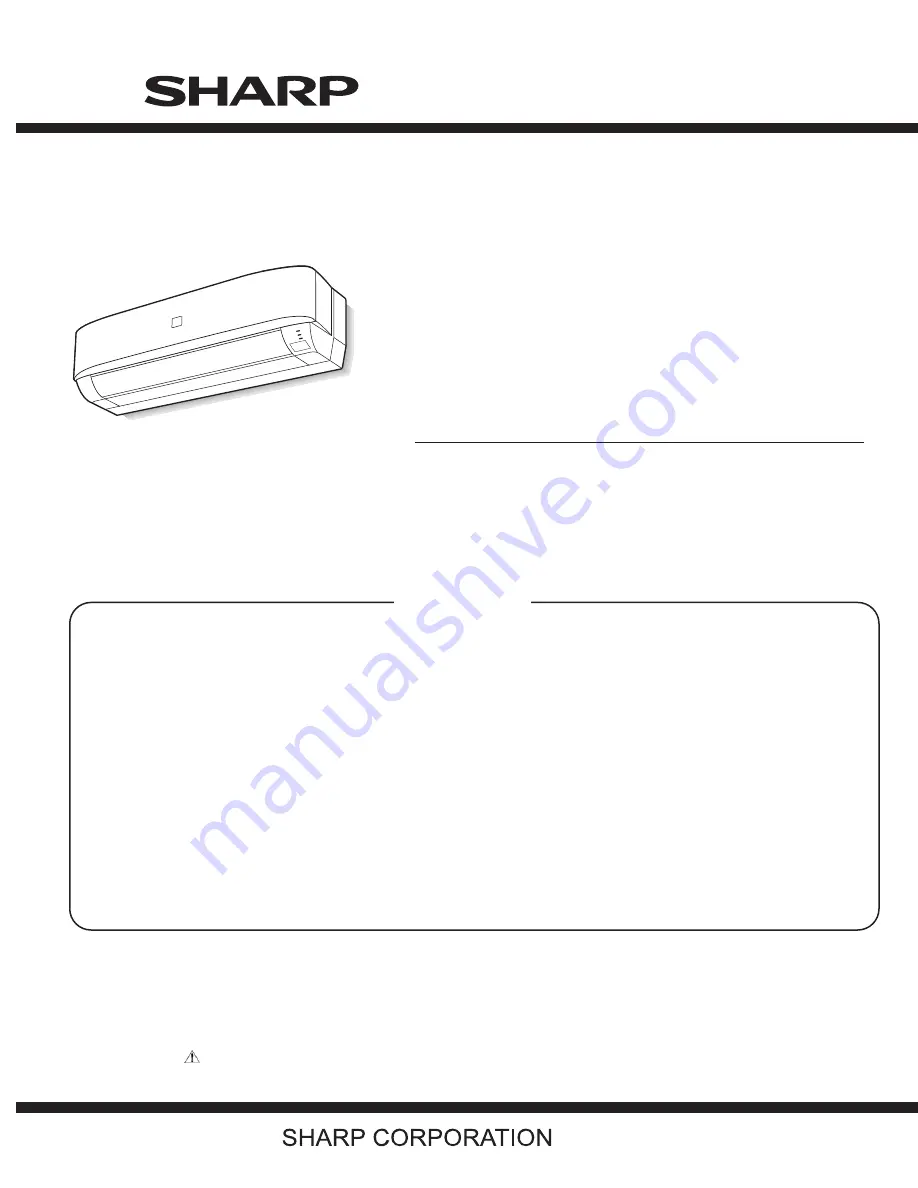

PLASMACLUSTER UNIT

SERVICE MANUAL

AY-XPC12PU

SB211AYXPC2PU/T

Parts marked with "

" are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

CHAPTER 1. PRODUCT SPECIFICATIONS

[1] SPECIFICATION............................................ 1-1

[2] EXTERNAL

DIMENTIONS............................. 1-2

[3] ELECTRICAL

PARTS .................................... 1-3

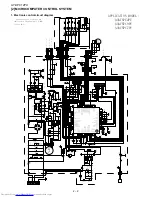

[4] WIRING

DIAGRAMS...................................... 1-3

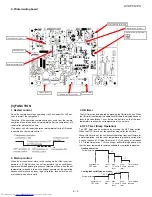

CHAPTER 2. EXPLANATION OF CIRCUIT AND

OPERATION

[1] BLOCK

DIAGRAMS....................................... 2-1

[2] MICROCOMPUTER CONTROL SYSTEM ........... 2-2

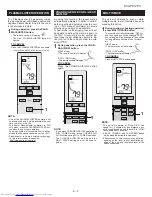

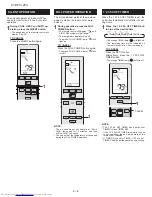

[3] FUNCTION..................................................... 2-3

[4] OPERATION

MANUAL .................................. 2-6

CHAPTER 3. TROUBLE SHOOTING GUIDE

[1] SELF-DIAGNOSIS

FUNCTION .....................3-1

[2] THERMISTOR

TEMPERATURE

CHAR-

ACTERISTICS...............................................3-8

.................................

....

3-8

3-9

CHAPTER 4. DISASSEMBLING PROCEDURE

[1] INDOOR

UNIT

INDOOR UNIT

...............................................4-1

CHAPTER 5. INSTALLATION INSTRUCTION

[1] .............................................5-1

[2] ..............................4-4

Parts Guide

TopPage

CONTENTS

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should

be restored to its original condition and only parts identical to those specified should be used.

AY-XPC07PU

AY-XPC09PU

AY-XPC12PU

[3] AIR CONDITIONER OPERATION IN

THERMISTOR ERROR

[4] GENERAL TROUBLESHOOTING CHART

SPLIT TYPE

ROOM AIR CONDITIONER

(INDOOR UNIT)

Summary of Contents for AY-XPC07PU

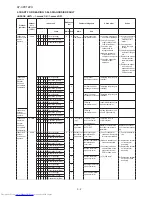

Page 34: ...AY XPC12PU 2 1 INDOOR UNIT PARTS ...

Page 35: ...AY XPC12PU 3 ...

Page 36: ...4 AY XPC12PU ...