Rankirw

(A,BorC)

t

roz-ara

PRINTER

UNIT

<

Printer head ranking position>

After

the above procedure,

adjust

by means of the

22-

Kohms protentiometer

so that an optimum

print quality is

obtalned.

The circuit has been so designed as to attain the

best result with the potentiometer

set at its midway_

Therefore,

existence of aremarkable

print density variation

might involve the following problems:

1.A>p

in head performance

2_~ality

change in the termal recording paper

3.

Throuble

in the thermal control circuit

1. When VR density Idjustment

is

needed

A) After

replacement

has been made in same electronic

component

parts inside the solid line.

B) When service request is placed from the user claiming

that print density is too low or high.

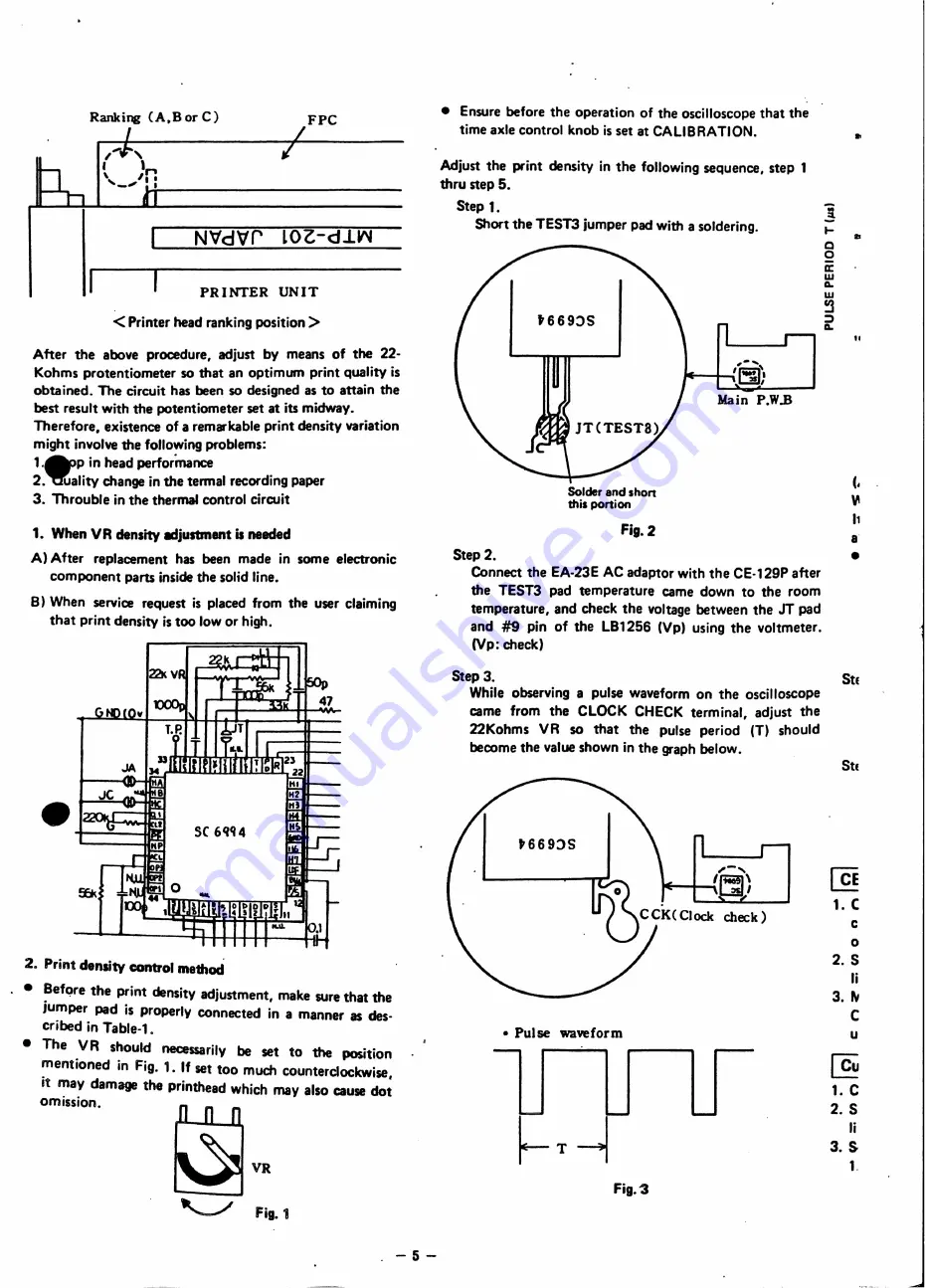

2. Print density control method

•

Before the print density adjustment,

make sure that the

jumper

pad is properly connected

in a manner

as des-

cribed in Table-1.

•

The

VR

should

necessarily

be set

to

the

position

mentioned

in Fig. 1. If set too much counterciockwise,

it may damage the printhead which mayaiso

cause dot

omission.

~VR

"-.J

FiS_'

. - 5-

•

Ensure before the operation

of the oscilloscope that the

time axle control knob is set at CALIBRATION.

Adjust the print density in the fOllowing sequence,

step 1

thru step 5.

Step 1.

Short the TEST3 jumper pad with a soldering.

t669:>S

,-,~

'1iiOn,

_.-

I

'LJ!I,

Solder and sho"

thispo"ion

Fig.2

Step 2_

Connect the EA-23E AC adaptor with the CE-129P after

the TEST3

pad temperature

came down to the room

temperature,

and check the voltage between the

JT

pad

and

#9

pin of the lB1256

(Vp) using the voltmeter.

(Vp: check)

..

~

I-

..

0

2

a:

w

11..

W

~

:)

11..

11

(,

~

11

a

•

Step 3.

StE

While observin9 a pulse waveform

on the oscilloscope

came

from

the

CLOCK CHECK terminal,

adjust

the

22Kohms

VR

so that

the

pulse

period

(T) should

become the value shown in the graph below.

t669:>S

• Pulse

waveform

Fig.

'3

StE

@

1. C

c

o

2. S

li

3. ~

C

u

~

1. C

2. S

li

3. S

1.

Do not sale !