2-

1

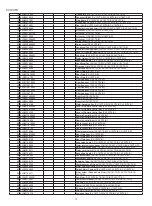

CV10CTX

CHAPTER 2. ATTENTION WHEN REPAIRING

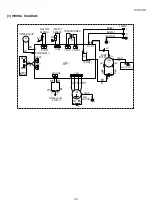

[1] HOW TO REPAIR REFRIGERATION

[1] HOW TO REPAIR REFRIGERATION

Before sealed system work can be preformed a refrigerant recovery EPA and LOCALLY approved certification is required,

additionally, EPA and LOCALLY approved refrigerant recovery equipment is required.

1. Sealed system repair

Sealed system repairs should be properly diagnosed before

entering into a repair of the system.

It is important to follow proper procedures when doing a system

repair for safety reasons and that the repair will result in a

restoration of the system to proper factory standards.

2. Safety reminders

1) Do not heat any system component with an open flame for

any reason.

2) Do not solder until you are sure that all refrigerant has been

removed from the system.

3) Do not heat the charging cylinder with an open flame. Use

warm water only and do not exceed 125 F (not too hot to keep

your hand in.)

4) Do not over fill any charging cylinders, as they could explode

when over filled.

5) Use proper wrenches.

6) Use safety goggles when working with refrigerants.

7) Keep a fire extinguisher within easy reach.

8) Watch flame direction when soldering so as not to burn

clothing, wiring or other components.

9) Solder in a well ventilated area. If a high concentration of

freon is present, an open flame will create phosgene gas which

can be harmful.

3. Proper soldering

Joint clearances should be maintained so that the brazing alloy

will flow between the closely mated surfaces rather than forming

large fillets.

This films make the strongest joints, capillary attraction also work

best with close tolerance.

The best clearance is between 0.01" to 0.03", the amount of lap

will be approximately 3/8" depending on the swaging tool used.

4. Cleaning tubing

To make a sound, leak tight joint, the brazing alloy when raised

to brazing temperature, must wet and flow freely over the entire

surface of the tubing in the joint area.

To assure this, the tubing surfaces must be free of all dirt,

grease, oil and oxides otherwise the alloy will not wet and flow

properly over any surface with these elements present. Cleaning

can be done with an abrasive cloth or steel wool. Never blow

into the tubing because this will introduce a lot of moisture into

the system. Open tubing joints should be covered if exposed for

long periods of time.

5. Proper fluxing

Flux is necessary when using silver solder; it is not required

when using silfos on copper to copper joints.

To do a good job the flux should cover the tube surface

completely. Be careful not to introduce any flux inside the tubing.

Fluxing should be done after the tubing is mated together and

just before brazing is done. Do not allow it to dry out.

When brazing, the flux should become entirely liquid and clear,

like water. The temperature will be at 1100 F and only a little

more heat will allow the alloy to flow freely into the joint.

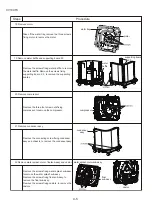

GOOD FIT

POOR FIT

Joint Clearance.

PROPER

JOINT FIT

CLEARANCE

0.2mm TO 0.6mm

EMERY CLOTH

KEEP TUBE IN

DOWNWARD POSITION

Cleaning Tubing.

INNER CONE

TORCH STEM

SILVER ALLOY

Directing Torch Flame to Copper Tubing.

10mm