14

DV-NC55U/C/M

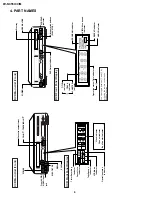

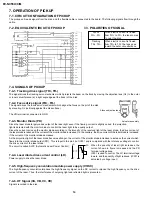

7. OPERATION OF PICKUP

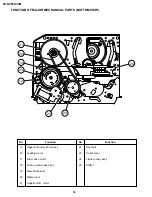

7-1. CIRCUIT CONFIGURATION OF PICKUP

The pickup unit reads signals from the disk, and the flexible cable is connected to the board. The following signals flow through the

cable.

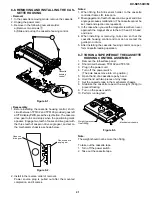

7-2. EQUIVALENT CIRCUIT OF PICKUP

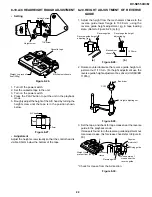

7-3. POLARITIES OF SIGNAL

Focus

When electric current is flowed

FO+, FO-

from FO+ to FO-, the lens comes

to near the disk.

Tracking

When electric current is flowed

TR+, TR-

from TR+ to TR-, the lens goes

toward the outer circumference.

FO+

TR–

TR+

FO–

ACTUATOR

OSC

V

OS

–

+

–

+

–

+

–

+

HOLOGRAM LASER UNIT

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

TR–

FO+

TR+

FO–

VR

PD

V

CC

GND

LD

GND

V

OS

NC

NC

V

ref

(VCC/2)

VA

VD

NC

GND

VB

VC

(NC)

Power adjust

HIGH-FREQUENCY CONVOLUTION

LD

PD

VA

VB

VC

VD

V

ref

V

cc

GND

7-4. SIGNALS OF PICKUP

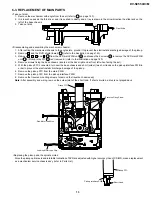

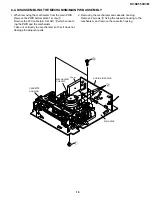

7-4-1. Tracking drive signal (TR+, TR-)

The signal drives the tracking servo mechanism which projects the beam on the track by moving the objective lens (OL) to the outer

or inner circumference (at a right angle against the track) of the disk.

7-4-2. Focus drive signal (FO+, FO-)

The signal drives the focus servo mechanism which aligns the focus on the pit of the disk

by elevating OL (vertically against the disk surface.)

The VR terminal is connected to GND.

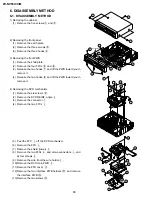

2-focus objective lens

Actuator assembly

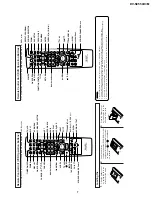

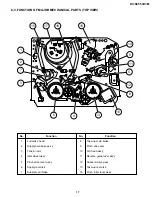

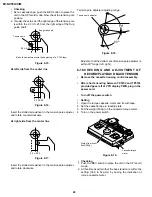

7-4-3. Monitor Diode (PD)

Since the laser diode largely varies output of the laser light even if the flowing current is slightly varied, the projection

light is detected with the monitor diode to control the laser light to be equally output.

Since the current varies on the monitor diode according to the intensity of the received light of the laser diode, the drive current of

the laser diode is reduced if the current of the monitor diode increases. On the contrary, the drive current of the laser diode is increased

if the current of the monitor diode decreases.

As the projection light of the laser diode becomes stronger, the current of the monitor diode increases to increase the current which

flows into the monitor diode output (PD). This is input to the pin 44 of IC301 and is compared with the reference voltage to control

the drive current of the laser diode.

The circuit is called ALPC (Automatic Laser Power Control).

7-4-4. Laser diode drive current control (LD)

Power supply to drive the laser diode

7-4-5. High-frequency convolution module power supply (VOSC)

The high-frequency convolution imposes the high-frequency signal on the DC current to impose the high frequency on the drive

current of the laser. Thus, the interference of outgoing light and reflected light is prevented.

LD

PD

7-4-6. HF Signal (VA, VB, VC, VD)

Signals recorded in the disk

When the quantity of laser light increases, the

current shown in figure increases and the PD

terminal voltage rises.

IC301 is used to control. The LD terminal voltage

lowers, and the quantity of light reduces. (IC301 is

actuated by voltage input.)