17

FU-28H-S

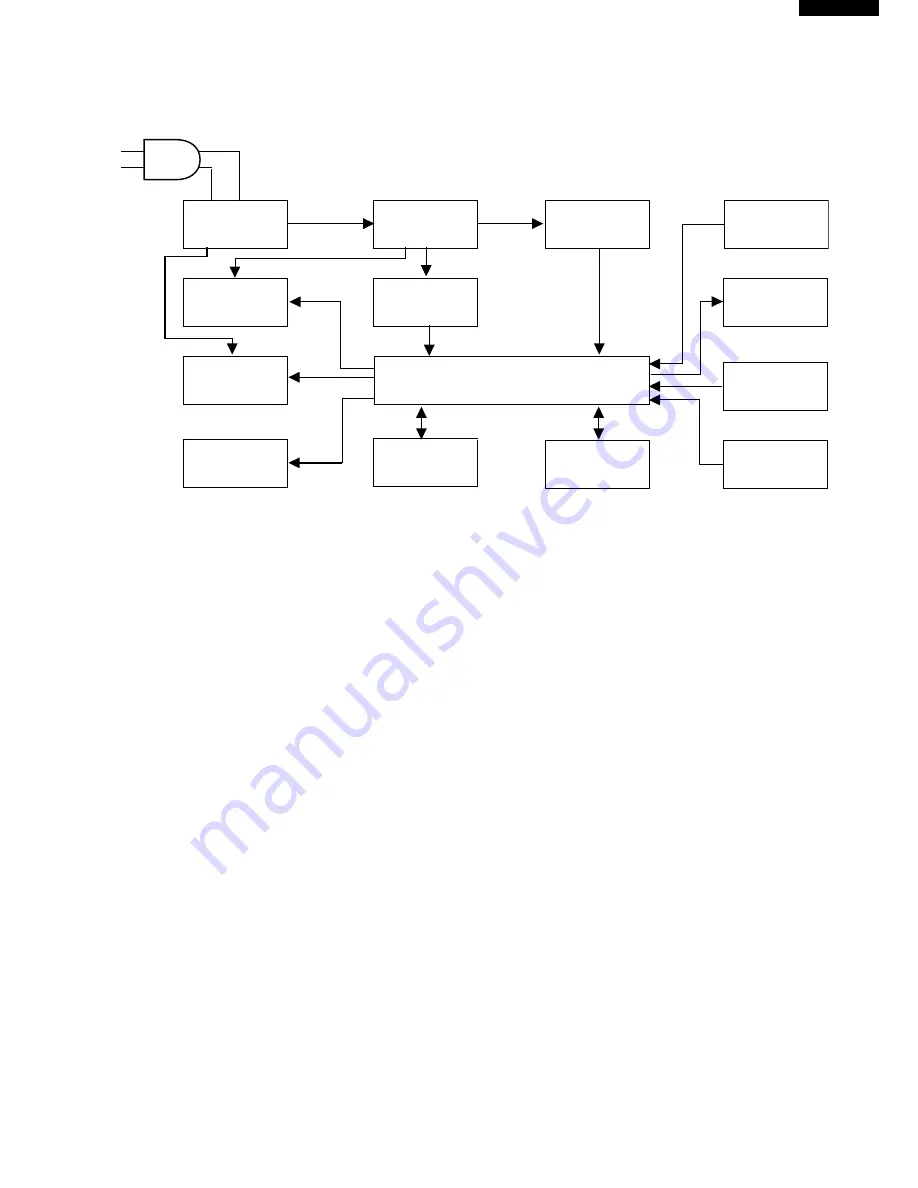

4. OPERATIONS

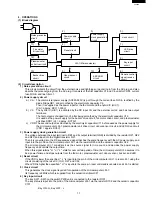

(1) Block diagram

Noise preventon

circuit

Power supply

circuit

Power supply

clock generation

circuit

clock circuit

LED drive

circuit

Fan motor

drive circuit

Reset circuit

Key input

circuit

Plasmacluster

unit drive circuit

Remote control

signal receive

circuit

Buzzer drive

circuit

EEPROM

circuit

Odour sensor

circuit

LSI-1 (Microcomputer)

1)

2)

3)

5)

10)

9)

13)

8)

11)

4)

7)

12)

6)

(2) Circuit description

1) Noise prevention circuit

This circuit protects the circuit from the external noise and lightning surge coming in from the AC plug, and also

absorbs the noise outgoing from the AC plug. It consists of the film capacitor C1 and C4, varistor VRS1, current

fuse FUSE, and line filter L1.

2) Power supply circuit

a) Vm: The commercial power supply (AC220-240V) is put through the current fuse FUSE, rectified by the

diode bridge DB1, and smoothed by the electrolytic capacitor C2.

Then it is supplied as the power input for the fan motor and the hybrid IC (HIC1).

(Vm = approx. DC311-339V)

b) VL:

The hybrid IC (HIC1) is activated by the DC input Vm and the external coil L2, and has two output

terminals.

The first output is changed into VL after being smoothed by the electrolytic capacitor C12.

It is used as the power supply for the buzzer drive circuit, fan motor drive circuit, and plasmacluster

unit drive SSR1 (VL = approx. DC15V).

c) VDD: The second output is smoothed by the electrolytic capacitor C11 before used as the power supply for

the microcomputer LSI-1, plasmacluster unit drive circuit, odour sensor circuit, and LED drive circuit

(VDD = approx. DC5V).

3) Power supply clock generation circuit

The voltage between the input terminal to DB1 and its output terminal (GND) is divided by the resistor R21, R22

and R23, and input into the digital transistor Q21.

Then it is converted into the DC square wave signal that has the same frequency with the AC power supply, and

input into the pin 38 on the microcomputer LSI-1 via the resistor R25 and the ceramic capacitor C22.

The microcomputer LSI-1 considers it as the source signal for time count, and decides the power supply

frequency and controls the output time.

When this signal retains " H " or " L " state for over certain period of time, the microcomputer LSI-1 assumes it to

be a power failure and stops outputs from the fan motor, plasmacluster unit, odour sensor, buzzer, and LED.

4) Reset circuit

If the VDD is lower than specified, " L " is input into the pin 8 of the microcomputer LSI-1 to reset LSI-1 using the

circuit consisting of the reset IC (IC-2), R31 and C32.

When VDD is higher than specified, " H " is input into the same pin, reset command is canceled, and LSI-1 is started.

5) Clock circuit

This generates the clock signal required for operation of the microcomputer LSI-1.

Its frequency is 8MHz which is supplied from the ceramic oscillator CF1.

6) Key input circuit

The key SW1 - SW3 on the switch PWB unit is connected to the resistor R101.

The key status is input into the pin 9 of the microcomputer LSI-1 via the resistor R102 and the ceramic capacitor

C101.

Key ON : H, Key OFF : L