InstallatIon Manual

b

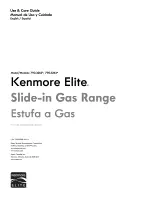

drIll pIlot holes and Fasten braCket

Drill a

1

/

8

-inch pilot hole where screws are to be located. If bracket

is to be mounted to the wall, drill pilot hole at an approximate 20

degree downward angle. If bracket is to be mounted to masonry or

ceramic floors, drill a

5

/

32

-inch pilot hole 1

3

/

4-

inches deep. The

screws provided may be used in wood or concrete material. Use a

5

/

16

-inch nut-driver or flat head screwdriver to secure the bracket

in place.

c

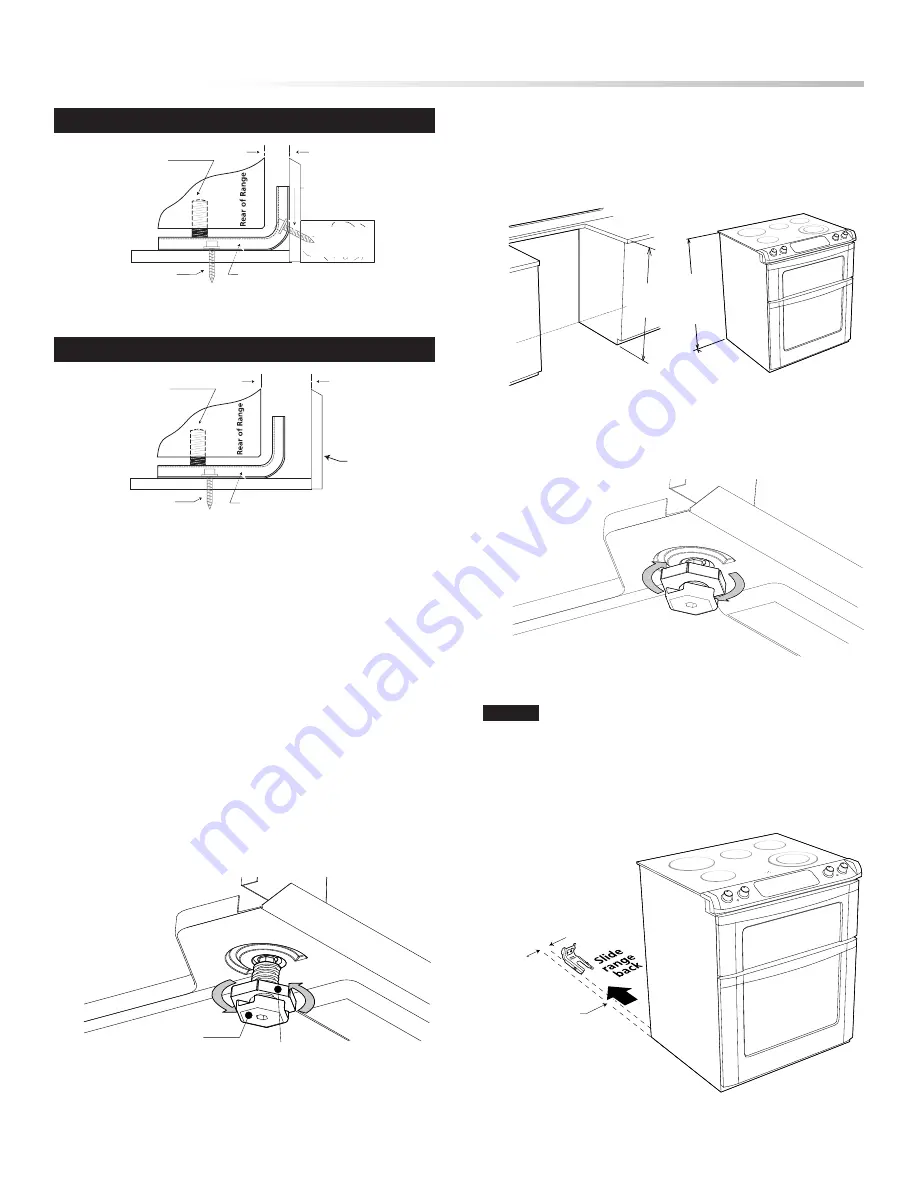

leVel and posItIon range

• Measure from the countertop to the floor height to determine

the height that the back of the range needs to be set at.

• Loosen legs and lock nuts to set level of the range. (Note that

the lock nuts are only on the rear feet). See Figure 16.

Figure 19

FASTEN BRACKET (WALL OR FLOOR MOUNTING)

FASTEN BRACKET (FLOOR MOUNTING ONLY)

floor mount

floor mount

Anti-Tip bracket

Anti-Tip bracket

wall

wall mount

wall plate

more than

11/4"

max 11/4"

leveling leg

leveling leg

Figure 14

Figure 15

Range Leg

Lock Nut

(Rear leg only)

Figure 16

• Adjust the back leveling legs with an adjustable wrench or pliers.

Measure from the floor to the bottom of the cooktop glass (X)

and adjust the legs to match the measurement (Y) taken from

the cutout. See Figure 17.

(X")

floor to bottom

off cooktop

glass

(Y")

floor to top

of countertop

Figure 17

• After leveling, tighten the lock nuts on the rear to prevent the

feet from turning when sliding into position. See Figure 18.

Figure 18

note:

A minimum clearance of 1/8-inch is required between

the bottom of the range and the leveling leg to allow room for the

bracket. Use a level to check your adjustments. Plug range into

properly prepared electrical receptacle or if hard wired, check that

it was completed properly. Check floor condition for evenness and

stability. Slide range back into position. See Figure 19.

Range Slide

1 5/8" to edge

of bracket