6

·

2

6

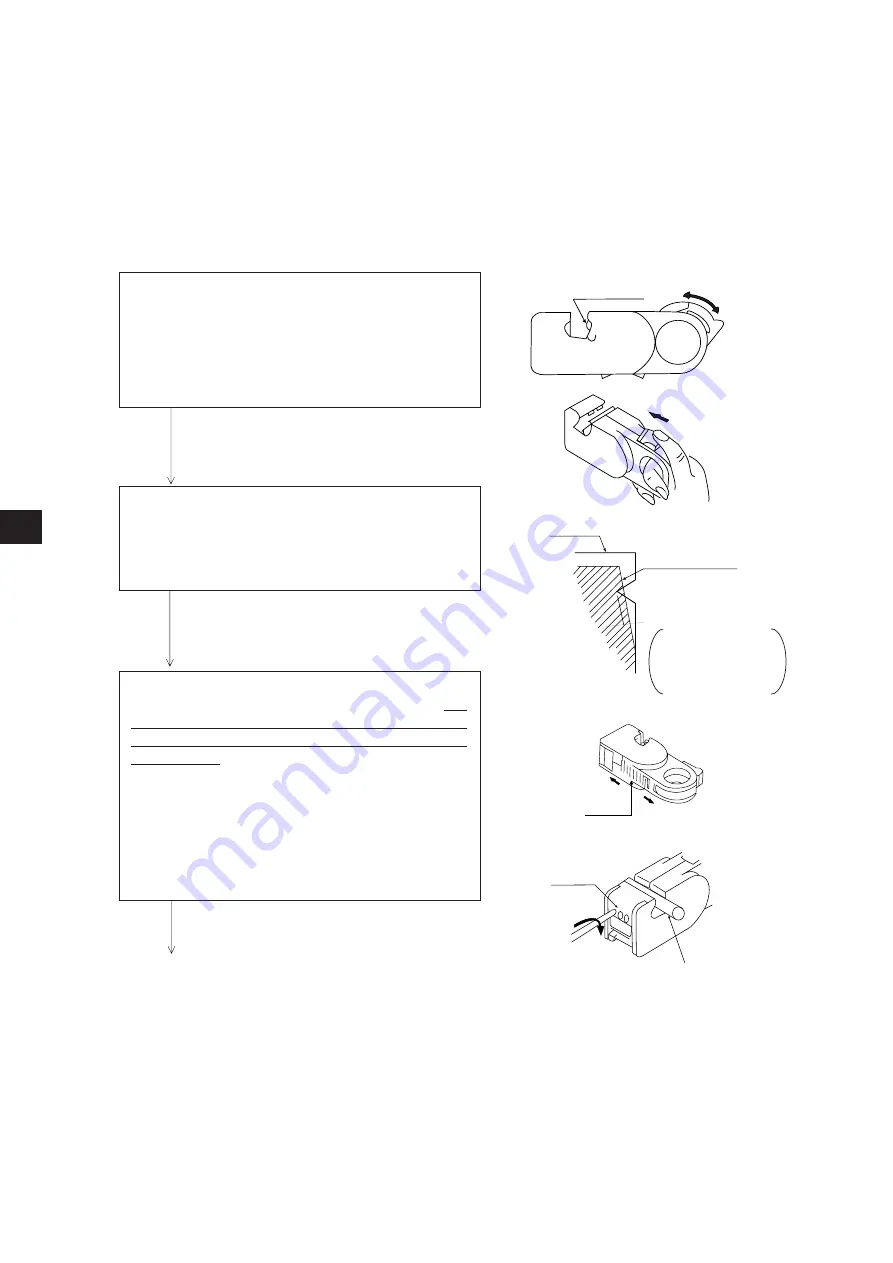

6-1 Processing cable end

①

Applicable cable

High frequency coaxial cable: ME-5C-2V

②

Required tools

Stripper for high frequency coaxial cable: CST-TM

③

Processing procedure

Blade cassette

Cam wheel

Rear

Blade (slashed area)

Within 1 mm

Slider

Blade setting gauge

Set the operation range of the cable holder by moving

the slider at the bottom of the body. Move to the left

to increase pressure.

In this example, set the slider to the cam wheel side’s

end (right side) to set the pressure to low.

Adjust the cutting depth of the blade by turning the

two screws at both ends of the screw holder. Set

the blade position to within 1 mm from the cutting

surface of the blade cassette prior to adjusting the

cutting depth. For the cutting depth adjustment, use

the “blade setting gauge” supplied as an accessory

and match the blade position with the caved position

of the gauge. Then move the cam wheel forward

and secure firmly. Turn right lightly both adjustment

screws at either end of the screw holder for

adjustment. (Be careful not to break the blade setting

gauge as it is made of aluminum.)

(Fine adjustment is required to get the

optimum cutting depth.)

Move the cam wheel of the stripper (amber colored

ring) back and forth and the cable holder moves back

and forth accordingly. Confirm this movement of the

stripper first.

To hold the stripper, put your forefinger through the

hole and move the cam while pushing back and forth

with your thumb.

<Basic operation>

<Pressure setting>

<Adjustment of blade cutting depth>

To the next page

Screw holder

Right

Left

Cam wheel

Front

Cable holder

Set the blade to within

1 mm in order not to

damage the blade by

the blade setting gauge.