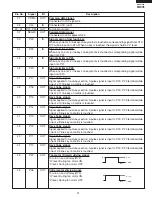

14

KB-6014LS

KB-6014LK

KB-6014LW

WARNING :

The oven should be fully assembled before following procedure.

(1) The oven should be plugged in at least two minutes before sensor cooking.

() Room temperature should not exceed 95

ο

F (35

ο

C).

(3) The unit should not be installed in any area where heat and steam are generated. The unit should not be

installed, for example, next to a conventional surface unit. Refer to the “INSTALLATION INSTRUCTIONS”

of the operation manual.

(4) Exhaust vents are provided on the back of the unit for proper cooling and air flow in the cavity. To permit

adequate ventilation, be sure to install so as not to block these vents. There should be some space for

air circulation.

(5) Be sure the exterior of the cooking container and the interior of the oven are dry. Wipe off any moisture

with a dry cloth or paper towel.

(6) The Sensor works with food at normal storage temperature. For example, chicken pieces would be at

refrigerator temperature and canned soup at room temperature.

(7) Avoid using aerosol sprays or cleaning solvents near the oven while using Sensor settings. The sensor

will detect the vapor given of by the spray and turn off before food is properly cooked.

(8) If the sensor has not detected the vapor of the food, ERROR will appear and the oven will shut off.

Water load cooking test

WARNING :

The oven should be fully assembled before following procedure.

Make sure the oven has been plugged in at least two minutes before checking sensor cook operation. The

cabinet should be installed and screws tightened.

(1) Fill approximately 00 milliliters (7. oz) of tap water in a 1000 milliliter measuring cup.

() Place the container on the center of tray in the oven cavity.

(3) Close the drawer.

(4) Touch the TIMER/CLOCK pad once, the POWER LEVEL pad twice and the START pad once. And touch

the number pads 1 once and the number pad 4 once. Now, the oven is in the sensor cooking condition,

and "AH0" and "ON" will appear in the display.

(5) The oven will operate for the first 16 seconds, without generating microwave energy.

NOTE: ERROR will appear if the door is opened or STOP/CLEAR pad is touched during first stage of sensor

cooking.

(6) After approximately 16 seconds, microwave energy is produced.

If ERROR is displayed or the oven does not turn off, replace the AH sensor or check the control unit, refer to

explanation below. If the oven stops after 5 minutes and no ERROR code is displayed, then the AH sensor

is normal. Check other parts except the AH sensor.

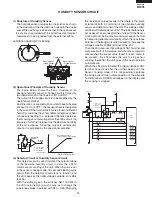

TESTING METHOD FOR AH SENSOR AND/OR CONTROL UNIT

To determine if the sensor is defective, the simplest method is to replace it with a new replacement

sensor.

(1) Disconnect the power supply cord, and

then disassemble as per "MICROWAVE DRAWER

DISASSEMBLY" page 5

.

() Open the drawer and block it open.

(3) Discharge high voltage capacitor.

(4) Remove the AH sensor.

(5) Install the new AH sensor.

(6) Reconnect all leads removed from components during testing.

(7) Re-install the covers.

(8) Reconnect the power supply cord after the covers are installed.

(9) Reconnect the oven to the power supply and check the sensor cook operation as follows:

9-1. Fill approximately 00 milliliters (7. oz) of tap water in a 1000 milliliter measuring cup.

F

AH SENSOR TEST

Checking the initial sensor cooking condition

11) Discharge high voltage capacitor.

1) Reconnect all leads removed from components during testing.

13) Re-install the outer case (cabinet).

14) Reconnect the power supply cord after the outer case is installed.

15) Run the oven and check all functions.

TEST PROCEDURES

PROCEDURE

LETTER

COMPONENT TEST