10

6. Operation:

1. Headstock:

a.

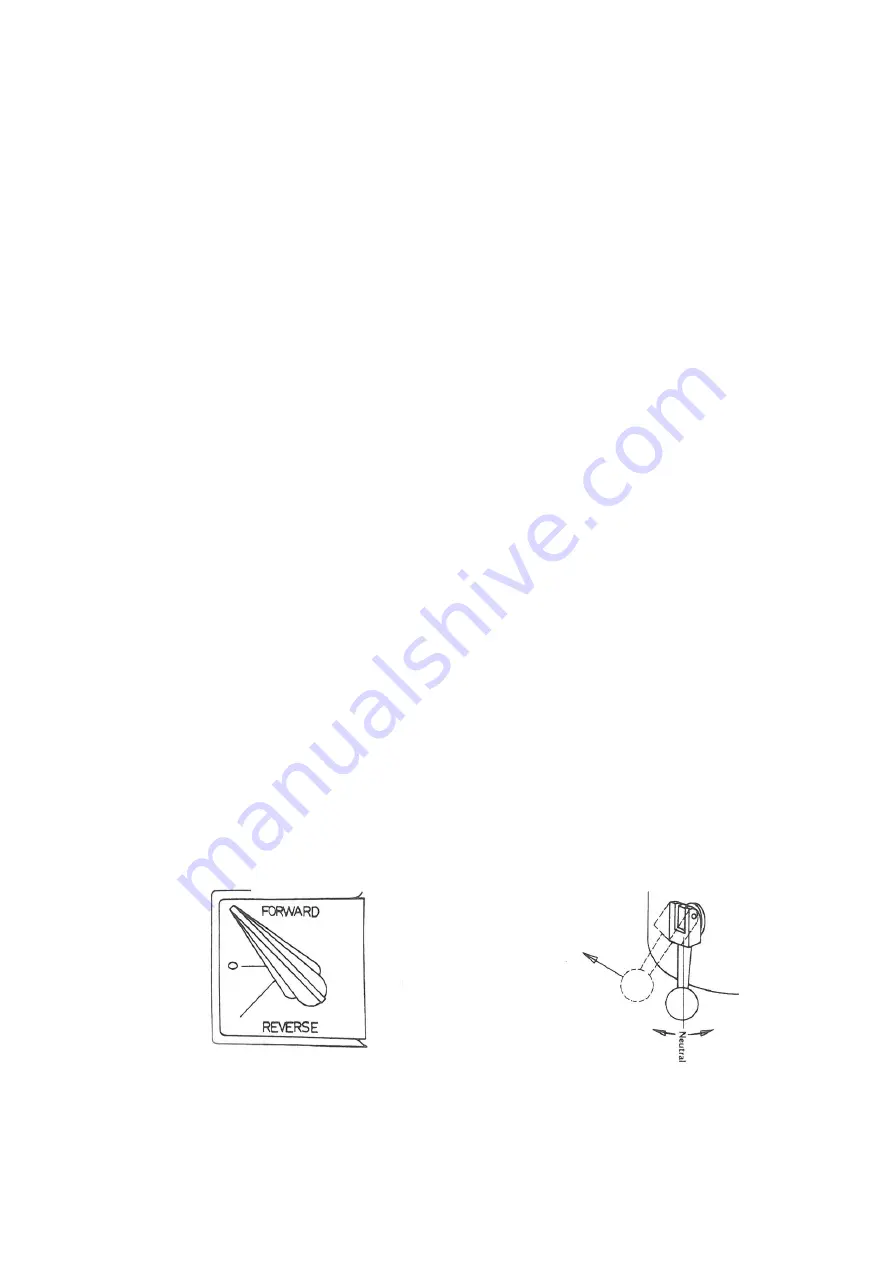

Power to the motor is controlled by a three way switch, forward,

reverse, and off (Fig. 9). When the high-low speed change lever (Fig.

3 (J), Page 3) is in high gear position and the switch is in FOR., the

spindle rotation is clockwise. When the switch is in REV., the rotation

is counter clockwise.

b. Spindle Brake:

To prevent damage and prolong the life of the brake, the power must

be off and the spindle must be below 200 RPM before engaging brake.

The brake can be engaged by pushing or pulling the brake lever (Fig.

10). Pulling the brake lever up after it is engaged can lock the brake.

Caution:

Be sure the brake is in neutral before starting the spindle.

c.

Installation of Collet:

1. Raise the spindle all the way up.

2.

Insert collet, being sure the keyway lines up with the pin

in the spindle.

3.

To tighten, turn the drawbar clockwise while brake is

engaged. To remove collet, loosen the drawbar (counter

clockwise) three to five turns and tap the drawbar with a soft

mallet to break the collet loose from the taper.

NOTE: When the mill is fitted with the R8 spindle, care must be taken that the collet keyway

is aligned with the pin in the spindle (Fig. 36, page 35).

Figure 9

Figure 10

Brake Setting

Brake

Brake

Summary of Contents for LMV Series

Page 8: ...4 DVS HEAD Emergency Stop Forward Reverse Switch Brake Speed Meter Speed Knob ...

Page 22: ...18 ...

Page 24: ...20 ...

Page 30: ...26 Figure 25 ...

Page 32: ...28 Figure 26 ...

Page 43: ...39 PARTS LIST ...

Page 45: ...41 DVS HEAD PARTS 1 ...

Page 47: ...43 DVS HEAD PARTS 2 ...

Page 49: ...45 ...

Page 50: ...46 ...

Page 55: ...51 ...

Page 59: ...55 ...

Page 62: ...58 ...

Page 64: ...60 ...

Page 66: ...62 ...

Page 68: ...64 ...

Page 70: ...66 ...

Page 72: ...68 ...

Page 74: ...70 ...

Page 76: ...72 ...

Page 78: ...74 ...

Page 81: ...77 ...

Page 84: ...80 ...