MAX

-

PRO Operator Manual

Original Printed in English

4

-

1

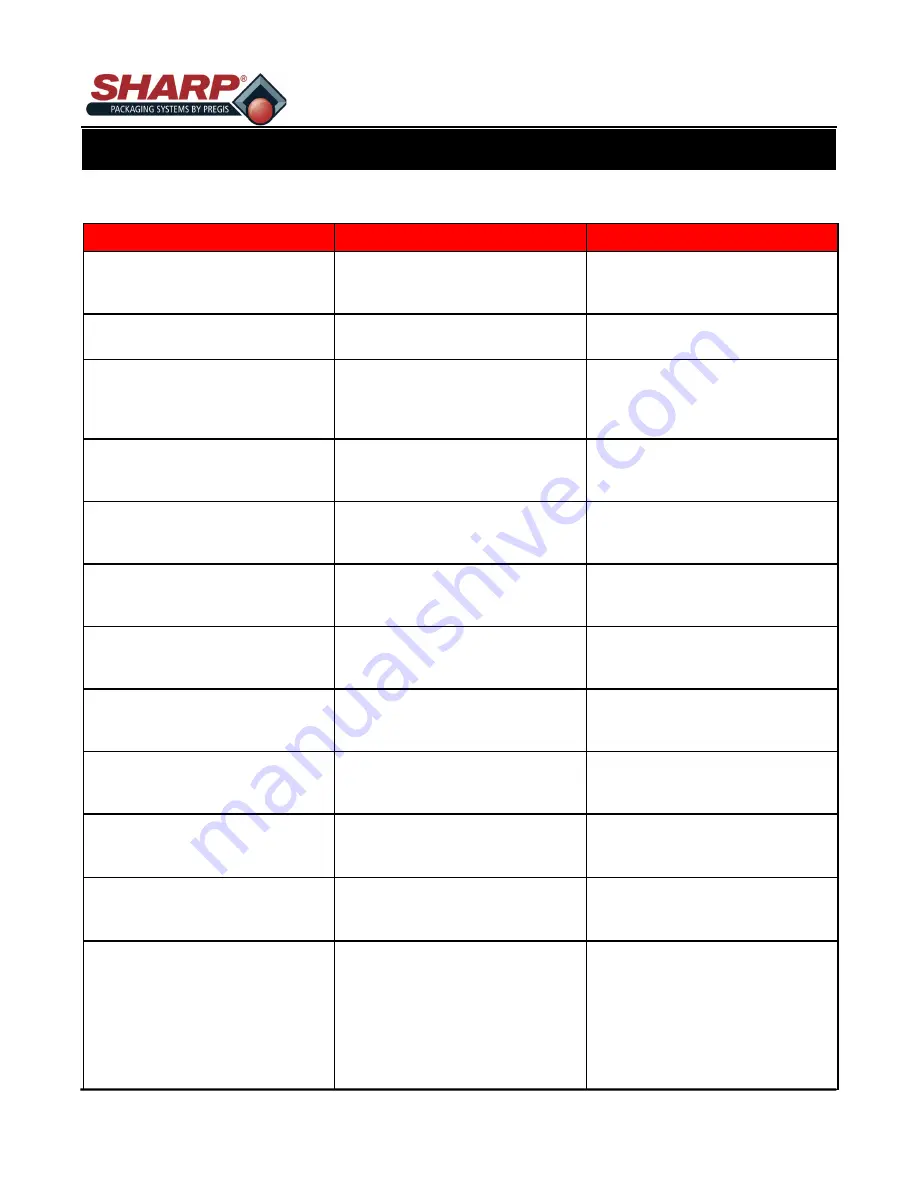

FAULT & ALERT MANAGEMENT

Fault

Cause

Possible Solution (S)

Pressure Bar Obstruction

The Pressure Bar attempted to

close, but was blocked by an ob-

struction.

This is usually a part that did not

drop past the Pressure Bar. In-

crease the Filler Drop Timer setting.

Reverse Fault

The bag film did not separate during

reversing.

Check bag length in job

No Bag Covering The Eye

There is no film in the machine or

the film is not being detected by the

Bag Edge Photo

-

Eye.

Press the Job Button once and the

bagger will jog the web for 10 sec-

onds until the Photo

-

Eye is covered

by film.

Pressure Bar Failed to Open

The commanded motion did not

complete before the fault time ex-

pired.

See Cylinder Motion Fault.

Pressure Bar Failed to Close

The commanded motion did not

complete before the fault time ex-

pired.

See Cylinder Motion Fault.

Seal Bar Temperature Sensor

Failure

Seal Bar temperature sensor is re-

porting as missing or broken wire

A qualified service person should

test the Thermocouple and its asso-

ciated circuits.

Safe Power Off

E

-

Stop Button was pressed or E

-

Stop is released but the Green Pow-

er Button has not been pressed.

Release the E

-

Stop, press the

Green Power Button, and the Bag-

ger Enabled button.

E

-

Stop tripped or Power not Re-

set

E

-

Stop Button was pressed or E

-

Stop is released but the Green Pow-

er Button has not been pressed.

Release the E

-

Stop, press the

Green Power Button, and the Bag-

ger Enabled button.

Seal Bar Thermal Runaway

-

Not

Heating

Seal Bar not heating up at all, or not

as quickly as expected.

A qualified service person should

test the Thermocouple and its asso-

ciated circuits.

Seal Bar Thermal Runaway

-

Overshoot

Seal Bar not cooling as quickly as

expected, or temperature is much

higher than expected

A qualified service person should

test the Thermocouple and its asso-

ciated circuits.

Out Of Bags

The bagger detected that the web is

broken or the bagger is out of bags.

Splice the broken web or replace

the empty roll/box.

Opened Bag Was Removed

A bag was opened and verified as

open by the Bag Open Sensor. The

opened bag was physically removed

or came off the Bag Opened Sensor

before the Filler could finish deliver-

ing its product.

Check that the Funnel door is pin-

ning the opened bag to the Pressure

Bar. Verify that the bag is properly

supported by the Load Shelf as it is

being filled. It may be that as the

bag is being filled, it shifts or slips

off the shelf and pulls the bag away

from the Funnel.

Faults are defined as an error condition that will stop the bagger and prevent subsequent cycles from occurring

as long as the fault persists. All faults must be cleared before resetting bagger.