MX-3114N MX-2314N/2614N/3114N (MAIN UNIT) 2 – 8

2)

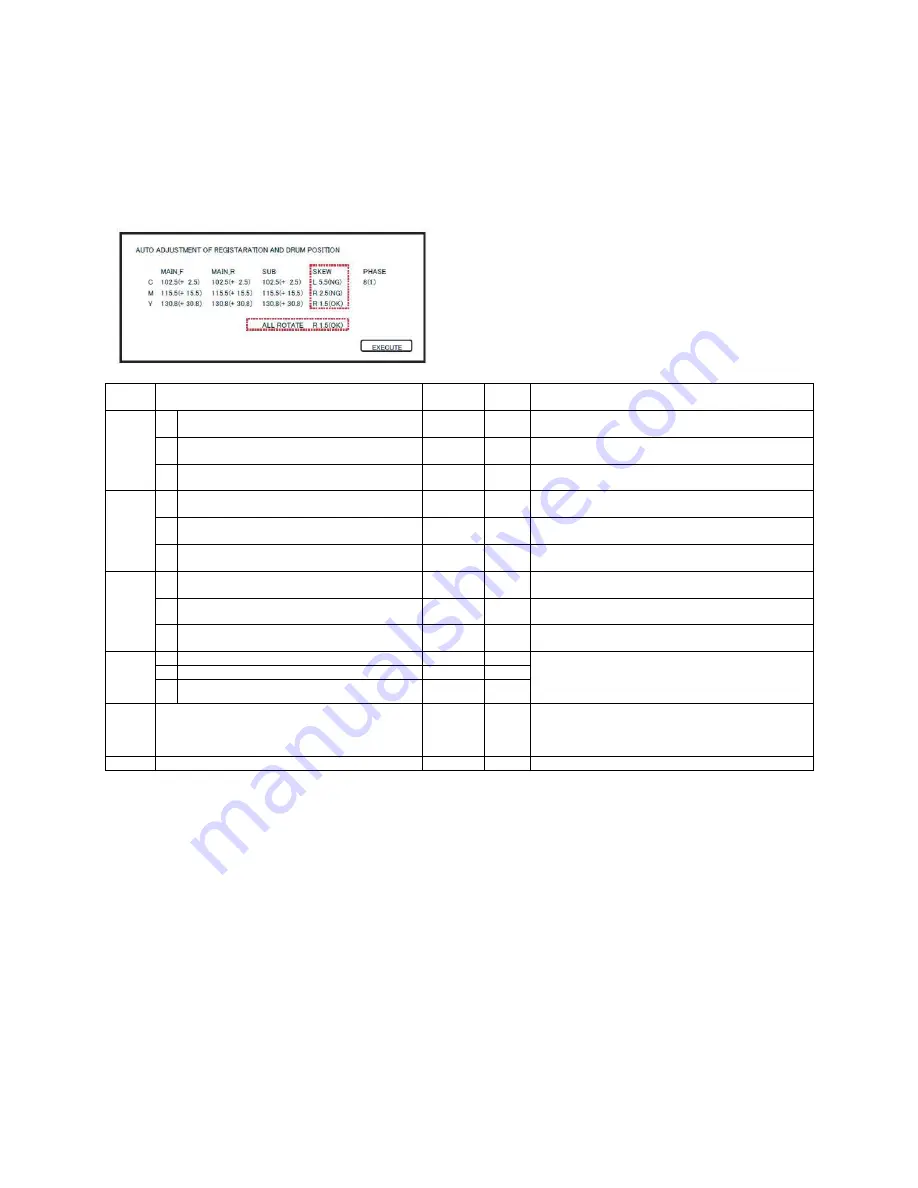

Press [EXECUTE] key.

[EXECUTE] key is highlighted and the image registration auto-

matic adjustment is started. (It takes about 15 sec to complete

the adjustment.)

3)

When the adjustment is completed, [EXECUTE] key returns to

the normal display, and the value of the adjustment result is

displayed.

The current skew level for each color is displayed on the

SKEW display section.

4)

Write down the displayed skew level.

(Meaning of the skew level value and the adjustment proce-

dure)

* If "OK" is displayed for all items of SKEW ALL_ROTATE, C,

M, and Y, there is no need to perform the adjustment.

* When "R" is displayed at the head of the value, turn the LSU

skew adjustment screw clockwise.

* When "L" is displayed at the head of the value, turn the LSU

skew adjustment screw counterclockwise.

* The turning amount of the adjustment screw corresponds to

each adjustment value. "ALL_ROTATE" indicates the num-

ber of rotations, and C, M, and Y indicate numbers of clicks.

The display value is rounded at the decimal point.

* "ALL_ROTATES" shows the number of rotations of adjust-

ments for all the adjustment screws. "C, M, and Y(SKEW)"

shows the number of adjustment click steps for each adjust-

ment screw of C, M, and Y.

Contents in ( )

MIAN, SUB: Difference from the previous adjustment value of

image registration.

Example:

If 105 for this time and 103 for the previous time,

it is displayed as 105.0 (+2.0).

SKEW, ALL_ROTATE: Judgment of the LSU skew adjustment

result. OK or NG.

PHASE: OPC drum phase adjustment value of the previous

time

Display/

Item

Content

Display

Default

NOTE

MAIN F

C

Registration adjustment value main scanning

direction (Cyan laser writing position F side)

1.0 - 199.0

100

M

Registration adjustment value main scanning

direction (Magenta laser writing position F side)

1.0 - 199.0

100

Y

Registration adjustment value main scanning

direction (Yellow laser writing position F side)

1.0 - 199.0

100

MAIN R

C

Registration adjustment value main scanning

direction (Cyan laser writing position R side)

1.0 - 199.0

100

M

Registration adjustment value main scanning

direction (Magenta laser writing position R side)

1.0 - 199.0

100

Y

Registration adjustment value main scanning

direction (Yellow laser writing position R side)

1.0 - 199.0

100

SUB

C

Registration adjustment value sub scanning direction

(Cyan drum

o

Black drum)

1.0 - 199.0

100

M

Registration adjustment value sub scanning direction

(Magenta drum

o

Black drum)

1.0 - 199.0

100

Y

Registration adjustment value sub scanning direction

(Yellow drum

o

Black drum)

1.0 - 199.0

100

SKEW

C

Print skew amount calculation result (Cyan)

-99.9 - 99.9

0

If the value is positive (+), "L" is displayed at the head of the

value. If negative (–), "R" is displayed.

If the value is in the range of –2.1 - +2.1, "(OK)" is displayed at

the bottom of the value. In the other cases, "(NG)" is displayed.

M

Print skew amount calculation result (Magenta)

-99.9 - 99.9

0

Y

Print skew amount calculation result (Yellow)

-99.9 - 99.9

0

ALL_

ROTATE

Print skew amount calculation result (Overall)

-99.9 - 99.9

0

If the value is positive (+), "L" is displayed at the head of the

value. If negative (–), "R" is displayed.

If the value is in the range of –1.6 - +1.6, "(OK)" is displayed at

the bottom of the value. In the other cases, "(NG)" is displayed.

PHASE

OPC drum phase adjustment value

1 - 8

1