oe

..,.

I

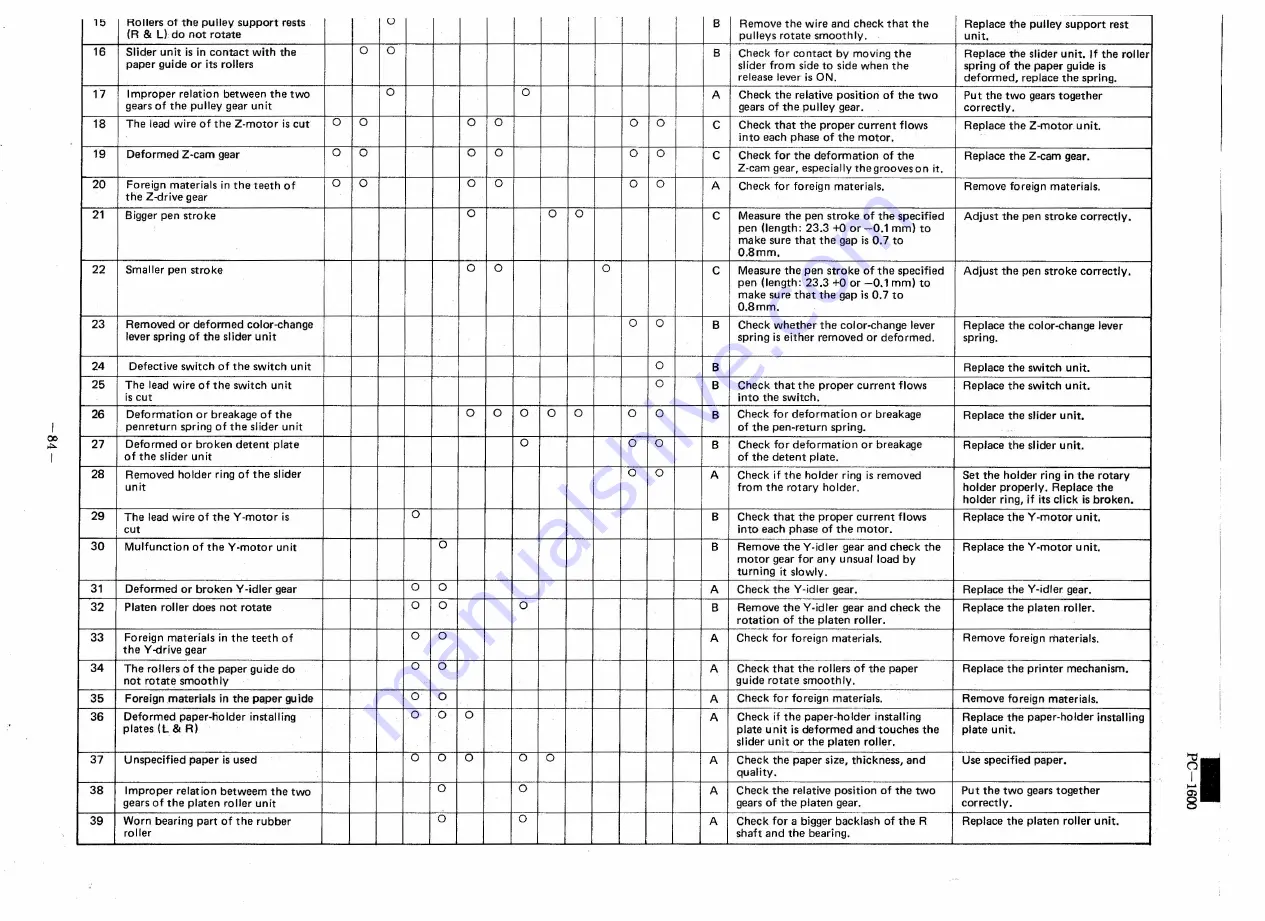

15

ROllers of the pulley

support

rests

0

B

Remove

the wire and check that the

Replace

the pulley support

rest

(R

&

L)

do not rotate

pulleys

rotate

smoothly.

unit.

16

Slider unit is in contact

with the

0

0

B

Check for contact

bv moving the

Replace

the slider unit.

If the roller

paper

guide or its rollers

slider from side to side when the

spring of the paoer guide is

release lever is

ON.

deformed,

replace

the spring.

17

Improper

relation

between

the two

0

0

A

Check the relative

position

of the two

Put the two gears together

gears of the pulley gear unit

gears of the pulley

gear.

correctly.

18

The lead wire of the Z·motor

is cut

0

0

0

0

0

0

C

Check that the proper

current

flows

Replace

the Z-motor

unit.

into each phase of the motor.

19

Deformed

Z·cam

gear

0

0

0

0

0

0

C

Check for the deformation

of the

Replace

the Z·cam

gear.

Z-cam gear, especially

thegrooveson

it.

20

Foreign

materials

in the teeth

of

0

0

0

0

0

0

A

Check for foreign

materials.

Remove

foreign

materials.

the Z-drive gear

21

B igger pen stro ke

0

0

0

C

Measure

the pen stroke

of the specified

Adjust

the pen stroke

correctly.

pen (length:

23.3

+0

or -0.1

mm) to

make sure that the gap is 0.7 to

0.8mm.

22

Smaller

pen stroke

0

0

0

C

Measure

the pen stroke

of the specified

Adjust

the pen stroke

correctlv,

pen (length:

23.3 +0 or -0.1

mm) to

make sure that

the gap is 0.7 to

0.8mm.

23

Removed

or deformed

color-change

0

0

B

Check whether

the

cotor-chanqe

lever

Replace

the color-change

lever

lever spring of the slider unit

spring is either

removed

or deforrned,

spring.

24

Defective

switch of the switch

unit

0

B

Replace

the switch

unit.

25

The lead wire of the switch

unit

0

B

Check that the proper

current

flows

Replace

the switch

unit.

is cut

into the switch.

26

Deformation

or breakage

of the

0

0

0

0

0

0

0

B

Check for deformation

or breakage

Replace

the slider unit.

penreturn

spring of the slider unit

of the pen-return

spring.

27

Deformed

or broken

detent

plate

0

0

0

B

Check for deformation

or breakage

Replace

the slider unit.

of the slider unit

of the detent

plate.

28

Removed

holder

ring of the slider

0

0

A

Check

if the holder

ring is removed

Set the holder

ring in the rotary

unit

from the rotary

holder.

holder

properly.

Replace

the

I

holder

ring, if its dick

is broken.

I

29

The lead wire of the Yrnotor

is

0

B

Check that the proper

current

flows

Replace

the Y-mctor

unit.

I

cut

into each phase of the motor.

30

Mulfunction

of the Y-rnotor

unit

0

B

Remove

the

Yvidler

gear and check

the

Replace

the V -motor

u nit.

rnotor

gear for any unsual

load by

I

turning

it slowly.

31

Deformed

or broken

V -idler gear

0

0

A

Check the V-idler gear.

Replace

the V-idler gear.

32

Platen

roller does not rotate

0

0

0

B

Remove

the Y-idler gear and check the

Replace

the platen

roller,

rotation

of the platen

roller.

33

Foreign

materials

in the teeth

of

0

0

A

Check for foreign

materials.

Remove

foreign

rnaterials,

the V -drive gear

34

The rollers of the paper guide do

0

0

A

Check that

the rollers of the paper

Replace

the printer

mechanism.

not rotate

smoothly

guide rotate

smoothly.

35

Foreign .materials

in the paper gu ide

0

0

A

Check for foreign

materials.

Remove

foreign

materials.

36

Deformed

paper-holder

installing

0

0

0

A

Check

if the paper-holder

installing

Replace

the paper-holder

installing

plates

(L

&

R)

plate unit is deformed

and touches

the

plate unit.

slider unit or the platen

roller.

37

Unspecified

paper

is used

0

0

0

0

0

A

Check the paper size, thickness,

and

Use specified

paper.

quality.

38

Improper

relation

betweem

the two

0

0

A

Check the relative

position

of the two

Pu t the two gears together

gears of the platen

roller unit

gears of the platen

gear.

correctly.

39

Worn bearing

part of the rubber

0

0

A

Check for a bigger backlash

of the R

Replace

the platen

roller unit.

roller

shaft and the bearing.

~I

Summary of Contents for PC-1600

Page 42: ... 11 CIRCUIT DIAGRAM PARTS POSITION KEY P W B LCD SIDE 39 ...

Page 43: ...PC l600 40 ...

Page 44: ...PC 1000 KEY P W B LSI SIDE 41 ...

Page 45: ... 42 ...

Page 48: ... PC l600 F P C P W B 45 ...

Page 49: ... Kn 46 ...

Page 52: ... PC l600 CONNECTOR P W B 49 ...

Page 53: ... 50 ...

Page 55: ... __ PC l600 tli I ONLY Pc 1600K I I 1 I 52 l J ...

Page 56: ... PC l600 K MEMORY P W B ROM Cut c IJ O lJ1F C O lJ1F I Bend capacitor to inward ROM SIDE 53 ...

Page 57: ...RAM SIDE 54 ...

Page 61: ...I I 2 3 4 42 58 ...

Page 93: ... P W B LSI SIDE t 90 ...

Page 117: ... PC I600 ...