18

R-1610

R-1611

R-1612

6

4

5

1

2

3

6

4

5

1

2

3

A

B

C

D

E

F

G

H

A

B

C

D

E

F

G

H

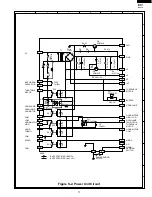

Figure S-3. LSI Unit Circuit

C-4

C-2

INT

GND

VC

LED

VR

TURNTABLE

MOTOR

OVEN LAMP

FAN MOTOR

HOOD LAMP

HOOD MOTOR

H / L

HOOD MOTOR

COM

NOTE

: IF NOT SPECIFIED, 1/10W

±

5%

BUZZER

MICRO

DOOR

AH SENSOR

NC

VA

C-3

C-10

C-9

C-11

C-12

C-1

C-13

C-5

C-6

C-15

C-8

C-14

G 8

5

0

4

9

3

8

2

7

1

6

G 7

Compu

Defrost

Night

Light

Stop

Clear

Memory

Cook

One Dish

Dinners

Lunch on

the Run

KEY UNIT

Work

Light

Power

Level

Frozen

snacks

Frozen

entrees

Beverage

center

Auto

Fan

Ground

meat

Sensor

reheat

Baked

potatoes

Fish/

seafood

Fresh

vegetables

Frozen

vegetables

Poultry

Rice

Minute

Plus

Popcorn

Fan

Hi / Lo

Turntable

On / Off

Custom

Help

Breakfast

Bar

Super

Defrost

G 6

G 5

G 4

G 3

G 2

G 1

G14

G13

G12

G11

G10

G 9

Kitchen

Timer

Clock

START

Touch On

+

–

C-7

F-1

C10 47

µ

/16v

C90

0.1

µ

/50v

C17 0.1

µ

/50v

C91

0.015

µ

/25v

C20 0.1

µ

/50v

C12

0.1

µ

/50v

R12

15k

R96 3.57kD

R91 3.32kD

R10

1k

R40 4.7k

R102 37.5kF

R101 75kF

R100 150kF

R99 300kF

R98 620kF

R79 270k

R78 270k

R77 270k

R76 270k

R75 270k

R74 270k

R80

1M

C110

4.7k

ZD10

UDZ4.3B

R11

15k

(J10)

(J11) 4.7K

(J13) 4.7K

(J15) 4.7K

(J17) 4.7K

(J12)

(J14)

(J16)

R66

15k

R65

15k

R64

15k

R63

15k

R62

15k

R61

15k

R60

15k

R67

15k

C13

0.01

µ

/25v

C14

0.01

µ

/25v

C40

0.01

µ

/25v

C93

0.01

µ

/25v

C92

0.01

µ

/25v

C64 330p/50v

C65 330p/50v

C63 330p/50v

C62 330p/50v

C61 330p/50v

C60 330p/50v

Q11

DTA143EKA

D90 MA152WA

Q25

DTA143EKA

Q24

DTA143EKA

Q23

DTA143EKA

CF1 CST4.00MGW

Q30

DTA143EKA

Q20

DTA143EKA

Q22

DTA143EKA

Q21

DTA123JKA

I

H

E

DCB

A

GND

Q10

2SA1037AK

IC2

BA4558

IC1

IZA958DR

See Figure S-4.

R41 15k

R90 330 1w

R95

47k

R97

47k

R94

10k

R93

360kF

R92

1.8kF

SEG36

SEG5

SEG35

AN10

AN11

AVSS

P10

P11

P12

P13

P14

P15

P16

P17

X 1

X 2

VSS

OSC2

OSC1

TEST

RES

P20

P21

P22

P23

P24

P25

P26

P27

P30

P31

P32

P33

P91

P90

P87

P86

P85

P84

P83

P82

P81

P80

P77

P76

P75

P74

SEG20

SEG19

SEG18

SEG17

SEG16

SEG15

SEG14

SEG13

SEG12

SEG11

SEG10

SEG9

SEG8

SEG7

SEG6

SEG4

SEG3

SEG2

SEG1

COM1

COM2

COM3

COM4

VCC

V 0

V 1

V 2

V 3

VSS

CVCC

P37

P36

P35

P34

SEG37

SEG38

SEG39

SEG40

P40

P41

P42

IRQ0

AVCC

AN0

AN1

AN2

AN3

AN4

AN5

AN6

AN7

AN8

AN9

R68 15k

R69 15k

R70 15k

R71 15k

R72 15k

R73 15k

D20 1SS355

D41 1SS355

LD1

LD8

LD9

LD10

LD2

LD3

LD4

LD5

LD6

LD7

G

F

100

81

80

51

50

31

E

D

C

B

A

30

1

GH

I

F

CPU UNIT

F-2

F-3

+

5

6

4

8

7

IC2