R-210A

TABLE OF CONTENTS

Page

CAUTION, MICROWAVE RADIATION .............................................................................................................. 1

WARNING ............................................................................................................................................................ 1

PRODUCT SPECIFICATIONS ........................................................................................................................... 2

GENERAL INFORMATION ................................................................................................................................. 2

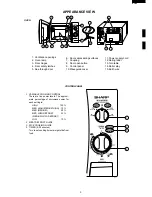

APPEARANCE VIEW ......................................................................................................................................... 3

OPERATION SEQUENCE ................................................................................................................................. 4

FUNCTION OF IMPORTANT COMPONENTS .................................................................................................. 5

SERVICING ........................................................................................................................................................ 6

TEST PROCEDURE .......................................................................................................................................... 8

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE ............................................................. 13

MICROWAVE MEASUREMENT ...................................................................................................................... 19

WIRING DIAGRAM .......................................................................................................................................... 20

PICTORIAL DIAGRAM ..................................................................................................................................... 21

PARTS LIST ...................................................................................................................................................... 22

In interests of user-safety the oven should be restored to its original

condition and only parts identical to those specified should be used.

MODEL

R-210A

SX737R210APT/

MICROWAVE OVEN

SHARP CORPORATION

SERVICE MANUAL

MED LOW

MED HIGH

LOW

TIMER

COOKING CONTROL

DOOR OPEN

MED

HIGH

RICE

DEFROST

0.5

1.0

2

4

DEFROST kg

RICE

Summary of Contents for R-210A

Page 2: ...R 210A ...

Page 28: ...R 210A 26 97SHARP CORP 11K0 100E Printed in Japan ...