R-3V97

MICROWAVE MEASUREMENT

After adjustment of door latch switches, monitor switch

and door are completed individually or collectively, the

following leakage test must be performed with a survey

instrument and it must be confirmed that the result meets

the requirements of the performance standard for micro-

wave oven.

REQUIREMENT

The safety switch must prevent microwave radiation emis-

sion in excess of 5mW/cm2 at any point 5cm or more from

external surface of the oven.

PREPARATION FOR TESTING:

Before beginning the actual test for leakage, proceed as

follows;

1. Make sure that the test instrument is operating normally

as specified in its instruction booklet.

Important:

Survey instruments that comply with the requirement for

instrumentations as prescribed by the performance

standard for microwave ovens must be used for testing.

Recommended instruments are:

NARDA 8100

NARDA 8200

HOLADAY HI 1500

SIMPSON 380M

2. Place the oven tray into the oven cavity.

3. Place the load of 275

±

15ml of water initially at 20

±

5˚C in the centre of the oven tray. The water container

should be a low form of 600 ml beaker with inside

diameter of approx. 8.5cm and made of an electrically

non-conductive material such as glass or plastic.

The placing of this standard load in the oven is important

not only to protect the oven, but also to insure that any

leakage is measured accurately.

4. Close the door and turn the oven ON with the timer set

for several minutes. If the water begins to boil before the

survey is completed, replace it with 275ml of cool water.

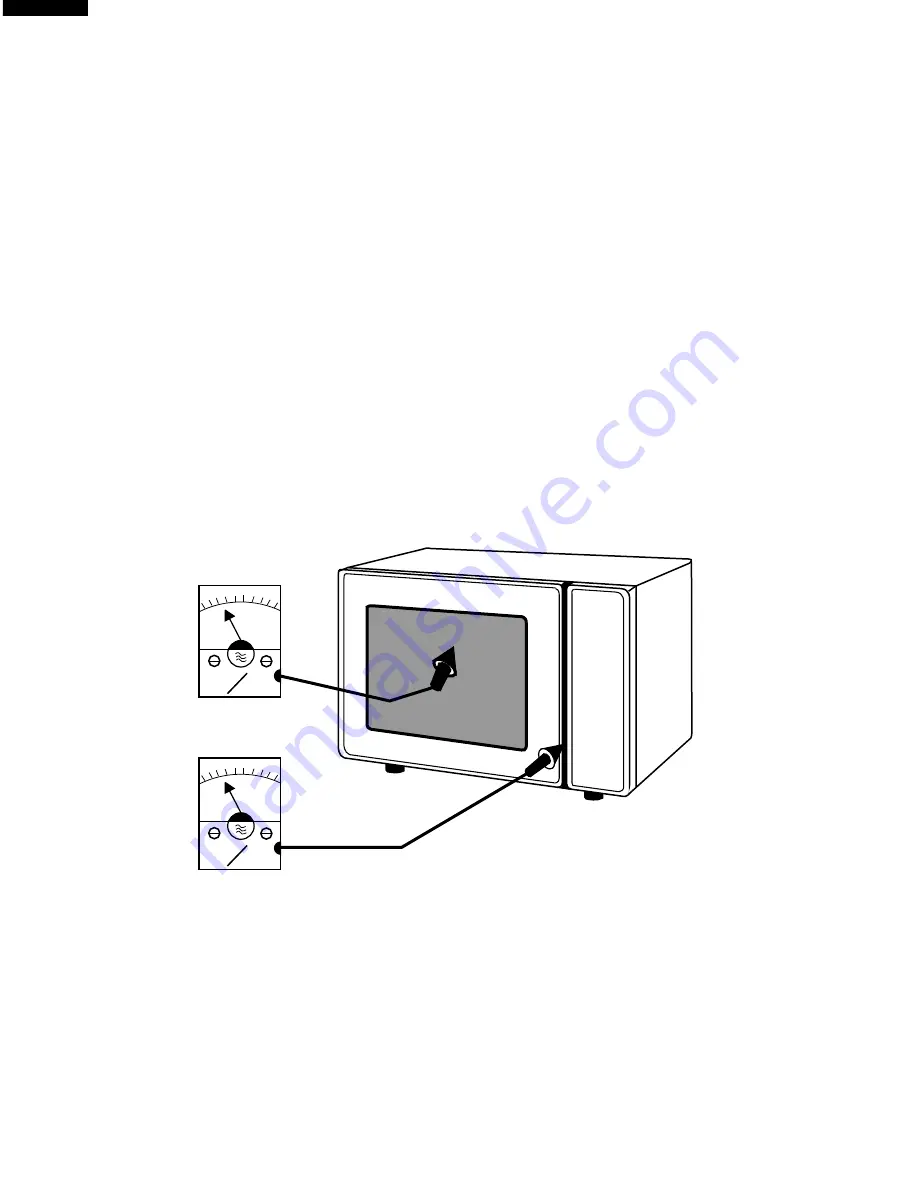

5. Move the probe slowly (not faster that 2.5cm/sec.)

along the gap.

6. The microwave radiation emission should be measured

at any point of 5cm or more from the external surface of

the oven.

mW cm

2

mW cm

2

Microwave leakage measurement at 5 cm distance

SHARP