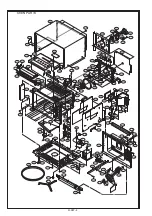

R-967 - 1

TABLE OF CONTENTS

REF No PART CODE DESCRIPTION QTY CODE

CH

RHET-A269WRZZ

Convection heating element

1

AV

CM

RMOTEA415WRZZ

Convection motor

1

AV

3-2

DPWBFA192URK0

CPU/LCD assy

1

BL

3-5

FUNTKC138URE0

Key sheet(R-967(W))

1

AS

3-5

FUNTKC139URE0

Key sheet(R-967(IN))

1

AS

4-4

DOVN-A024URK0

Cavity assy

1

BH

4-20

PPIPFA005UR10

Pipe

1

AD

4-21

PSKR-A013URP0

Air separate angle A

1

AC

4-22

PSKR-A014URP0

Air separate angle B

1

AC

4-23

PSKR-A015URP0

Air separate angle C

1

AC

4-24

PSKR-A016URP0

Air separate angle D

1

AC

4-28

PSKR-A012URP0

Air separate angle E

1

AC

4-30

NFANMA004URP0

Convection fan

1

AE

4-32

PDUC-A019URP0

Convection duct

1

AP

5-1

CDORFS028URK0

Door assy (R-967(IN))

1

BN

5-1

CDORFW026URK0

Door assy (R-967(W))

1

BM

5-1-4

JHNDPS201URT0

Door handle (R-967(IN))

1

AW

5-1-4

JHNDPW200URF0

Door handle (R-967(W))

1

AW

5-1-7

PGLSPA031URR0

Front door glass (R-967(W))

1

AX

5-1-9

XCTSD40P20000

Screw

2

AA

5-1-10

JHNDPK205URF0

Handle cover (R967(IN))

1

AW

5-1-10

JHNDPW205URF0

Handle cover (R-967(W))

1

AW

6-6

TINS-A317URR0

Operation manual

1

AS

6-7

TCADCA015URR0

Cook book

1

AU

6-12

TINS-A319URR0

Quick start guide

1

AM

S30332R967EHW

SERVICE MANUAL

SHARP CORPORATION

MICROWAVE OVEN

GRILL AND CONVECTION

R- 967 (W/IN)

In interests of user-safety the oven should be restored to its original condition

and only parts identical to those specified should be used.

SUPPLEMENT

SUPPLEMENT

This service manual covers only those items that differ from the R-963(IN/W)

S07284R963EHW

.

For further information on items not covered by this supplement refer to the Service Manual

for R-963(IN/W) .