6. Adjustments relating to process control

(The adjustment procedures differ according to the state of service

maintenance.)

A. Adjustment when installing the machine

•

Unpack the machine (lock release).

•

Install and supply the supply parts.

•

Turn on the power.

(1)

Execute simulation No. 25-2.

Toner density reference value

setting

Over toned error

→

EE(EL)

Under toned error

→

EE(EU)

B. Adjustment in maintenance within the life of

supply part

•

Complete the maintenance.

•

Turn on the power.

(1)

Execute simulation No. 44-1. Process control state check

[+ 1] Process control correction valid

[+ 2] Optical system dirt correction valid

[+ 4] OPC drum film wear correction valid

[+10] Toner control A correction valid

[+20] Toner control B correction valid

Note: [37] All valid

For this adjustment, check that the setting value is "7."

(2)

Compulsorily execute simulation No. 44-6 process control.

(3)

Execute simulation No. 46-1 copy exposure adjustment.

Execute copy exposure adjustment according to the procedure

of [8]-5.

C. Adjustment when replacing the developer

•

Complete replacement of the developer.

•

Turn on the power.

(1)

Execute simulation No. 25-2.

Toner density reference value

setting

Over toned error

→

EE(EL)

Under toned error

→

EE(EU)

(2)

Execute simulation No. 46-1 copy exposure adjustment.

Execute the copy exposure adjustment according to the proce-

dure of [8]-5.

D. Adjustment when replacing the drum

(Photoconductor)

•

Complete replacement of the drum.

•

Turn on the power.

(1)

Execute simulation No. 24-7 drum film wear correction counter

reset.

(2)

Execute simulation No. 44-2 drum mark sensor level adjustment.

Standard value: 204

±

10

(3)

Execute simulation No. 44-6 compulsory execution of process

control.

(4)

Execute simulation No. 46-1 copy exposure adjustment.

Execute the copy exposure adjustment according to the proce-

dure of [8]-5.

E. Adjustments when replacing the developer and

the drum (photoconductor)

•

Complete replacement of the drum.

•

Complete replacement of the developer.

•

Turn on the power.

(1)

Execute simulation No. 24-7 drum film wear correction counter

reset.

(2)

Execute simulation No. 25-2 toner density reference value set-

ting

Over toned error

→

EE(EL)

Under toned error

→

EE(EU)

(3)

Execute simulation No. 44-2 drum mark sensor level adjustment.

Standard value: 204

±

10

(4)

Execute simulation No. 44-6 compulsory execution of process

control.

(5)

Execute simulation No. 46-1 copy exposure adjustment.

Execute the copy exposure adjustment according to the proce-

dure of [8]-5.

F. Adjustment when replacing/cleaning the drum

mark sensor

(1)

Execute simulation No. 44-2 drum mark sensor level adjustment.

Standard value: 204

±

10

G. Adjustment when replacing/cleaning the image

density sensor

(1)

Execute simulation No. 44-3 image density sensor level adjust-

ment.

Standard value: 204

±

10

H. Adjustment when replacing the sensor level

adjustment VR PWB

Execute the procedures of F and G in the above.

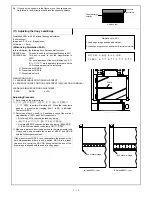

1. Note: This model emplyes the high-sensitivity drum,

which requires special care against pre-exposure.

1) Never expose the drum outside the bag. (Keep it in a

black bag.)

2) When istalling this model, avoid facing the front cover

toward a light source or window.

Avoid opening the front cover as far as possible.

2. Other note

1) If starting powder is attached to the density sensor

when replacing the drum/blade, it may cause faulty

operations of the sensor. Be sure to clean and remove

powder.

7 – 23

Summary of Contents for SF-2040

Page 27: ...9 Desk unit SF D23 11 12 16 17 13 18 10 9 8 7 6 2 5 4 3 1 23 21 22 19 20 14 15 4 10 ...

Page 63: ...5 5 C F 10 D 7 6 11 G E 8 9 H 12 6 2 ...

Page 65: ...3 B 3 E 13 C 4 5 6 7 8 F 14 D 10 11 9 6 4 ...

Page 67: ...2 1 3 A D 9 8 11 10 B 4 5 E 12 13 14 C 7 6 6 6 ...

Page 69: ...A a 1 1 D 4 4 B 1 b 1 1 E 5 5 7 6 8 9 8 5 C 2 3 3 F 5 11 12 6 8 ...

Page 71: ...1 2 3 3 4 5 A D 13 11 10 7 6 6 7 B E 14 8 12 9 C F 15 G 16 16 6 10 ...

Page 73: ...A a 1 D 11 10 10 9 8 B 4 2 3 E 13 12 12 C 5 7 6 7 6 12 ...

Page 75: ...C 4 F 9 9 9 10 9 5 6 D G 11 E 8 7 6 14 ...

Page 78: ...Volume PWB 8 9 10 10 6 17 ...

Page 80: ...C 5 F 11 P D F R 7 6 6 12 13 G 12 13 E 8 9 a 8 H 14 6 19 ...