2

SJ-P43N/43N

SJ-P47N/47N

Some household cleaning chemicals may affect the internal

food liner and plastic parts resulting in splitting or cracks

occurring.

When cleaning all plastic parts inside this refrigerator, only

use diluted dishwashing liquid(soapy water). Make sure that

all plastic parts are thoroughly rinsed with water after cleaning.

CAUTIONS AND INFORMATIONS

1. Some foods froze in the refrigerator compartment.

2. Some plastic parts were cracked or split.

Cracking or crunching sound;

Sound produced by expansion and contraction of inner walls and internal parts during cooling.

Squeaking sound;

Sound produced by expansion and contraction of internal parts.

Sound of flowing fluid (gurgling sound, fizzing sound);

Sound of refrigerant flowing in pipes (sound may become louder from time to time).

3. IT IS NORMAL for the refrigerator to produce the following sounds.

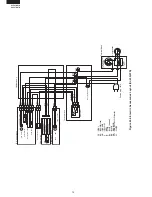

Do not place food directly in front of

cold air outlet.

This may lead to the food freezing.

IN

OUT

cold air flow

In case of following troubles, the cause is not related with the failure of refrigerator.

Please mention the correct way to the customer for the use of refrigerator when the repairing.