20

SJ-P43N/43N

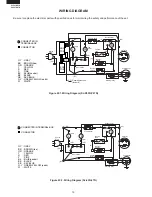

SJ-P47N/47N

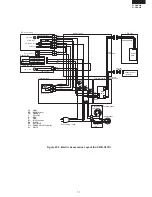

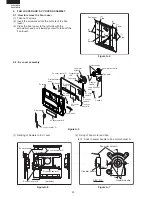

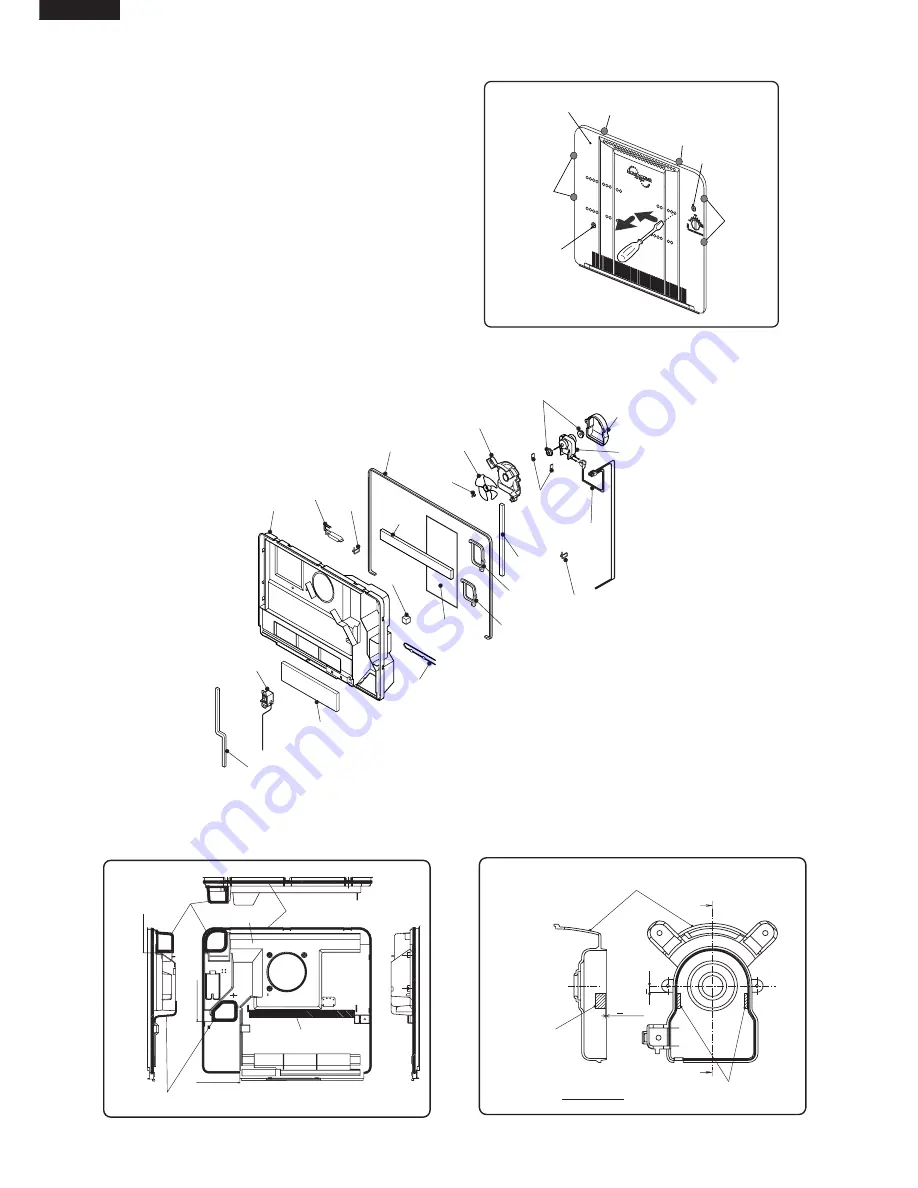

(2) Fixing of Fan motor and Fan

(2)-1 Stick U-sealer handle to Fan motor holder A.

Figure A-6

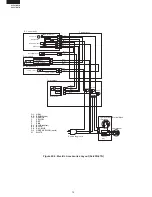

2. FAN LOUVER AND E.V COVER ASSEMBLY

Figure A-4

E.v cover sealer C

E.v cover

sealer C

Fuse ass’y

F-thermostat

E.v cover

Defrost thermo.

ass’y

E.v cover

sealer A

E.v cover

sealer G

L-band C

L-band C

Lead EV-cover

ass’y

U-sealer

handle

Fan motor

holder A

Fan clamp

Propeller fan

100

Fan motor holder B

Fan motor

Motor cushion

E.v cover

sealer B

E.v cover sealer D

E.v cover sealer E

E.v cover

AL A

E.v cover

sealer F

Fan motor holder A

U-sealer handle

U-sealer handle

7 2mm

+

+

0 1mm

C

C

SEC. C-C

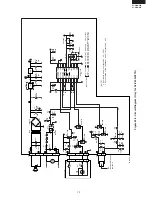

E.v cover sealer C

E.v cover sealer G

E.v cover sealer A

E.v cover sealer B

E.v cover

[back side]

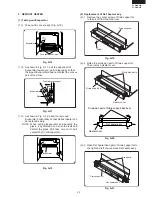

STICK START

STICK START

STICK START

(1)

(1)

(2)

(3)

(3)

(4)

(4)

(4)

Screw

Fan louver

Screw

Claw

Claw

Claw

Claw

2-1. How to remove the Fan louver

(1) Take out 2 screws.

(2) Insert the screwdriver into the air hole of the Fan

louver.

(3) Press the Fan louver to the left side with the

screwdriver,and pull it toward yourself to take off the

Fan louver.

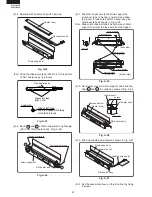

2-2. E.v cover assembly

Figure A-5

Figure A-7

(1) Sticking of Sealers to E.V cover