15

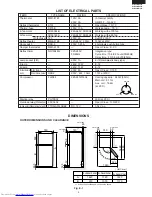

SJ-D59M/P60M

SJ-D64M/P65M

SJ-D69M/P70M

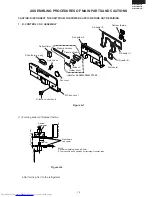

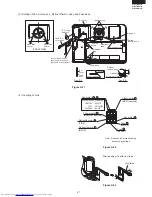

ASSEMBLING PROCEDURES OF MAIN PARTS AND CAUTIONS

CAUTION: DISCONNECT THE UNIT FROM THE POWER SUPPLY BEFORE ANY REPAIRING.

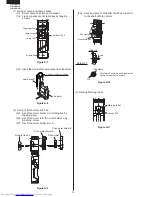

1. R-CONTROL COV. ASSEMBLY

(Only for SJ-P60M,P65M,P70M)

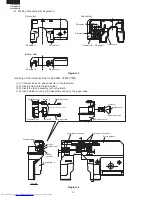

R-temp. control knob

Nylon band

Fan cover

R-C box cover

RA sealer B

RA sealer C

Dial sealer

R air guider A

RA sealer A

Damper thermo.

Defrost timer

R fan thermo. ass'y

Ionizer-K

Plasma holder

Holder cover

Plasma harness

Figure A-1

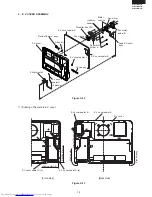

Figure A-2

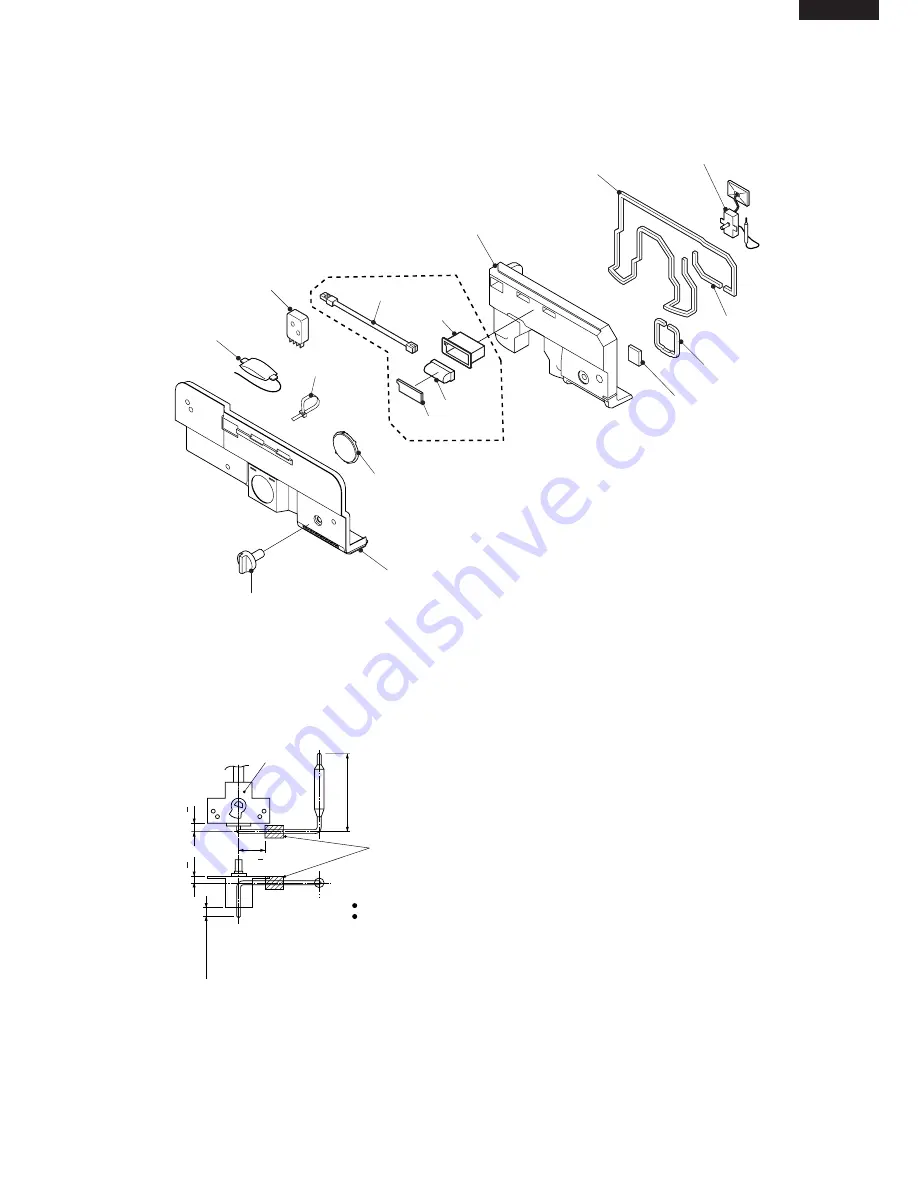

(1) Forming sensor of Damper thermo.

Stick thermo.

cap. sealer

Less than 130 m

m

Damper

thermostat

3

1

mm

5

1

mm

L

ess than 12 mm

25

2

mm

NOTE

Minimum bending radius is R5mm.

There should be no gas leak by reforming of sensor tube.

+

+

+

After forming, fix it to the refrigerator.