13

CARE AND CLEANING

Some household cleaning chemicals may affect the

inside surfaces and plastic shelves

resulting in splitting or cracks occurring.

When cleaning all plastic parts inside

this refrigerator, only use diluted dish-

washing liquid (soapy water). Make sure

that all plastic parts are thoroughly

rinsed with water after cleaning.

1.

Remove the shelves and pockets from the cabinet and

door. Wash them in warm soapy dishwashing water;

rinse in clean water and dry.

2.

Clean the inside with a cloth soaked in warm soapy

dishwashing water. Then, use cold water to wipe off

soapy water.

3.

Wipe the exterior with a soft cloth each time it is soiled.

4.

Clean the Magnetic door seal with a toothbrush and

warm soapy dishwashing water.

5.

Whenever the refrigerator is moved to clean or reposi-

tioned, the Evaporating pan should be removed and

cleaned.

NOTE:

•

Do not use polishing powder, benzine, hot water etc.

•

If undiluted detergent is used or soapy water is not

wiped off thoroughly, cracking of plastic parts can result.

•

Wipe any food oils adhered to plastic components as

they can cause cracking of the plastic surface.

•

The glass shelves weigh approximately 2kg each. Hold

firmly when removing from the cabinet or carrying.

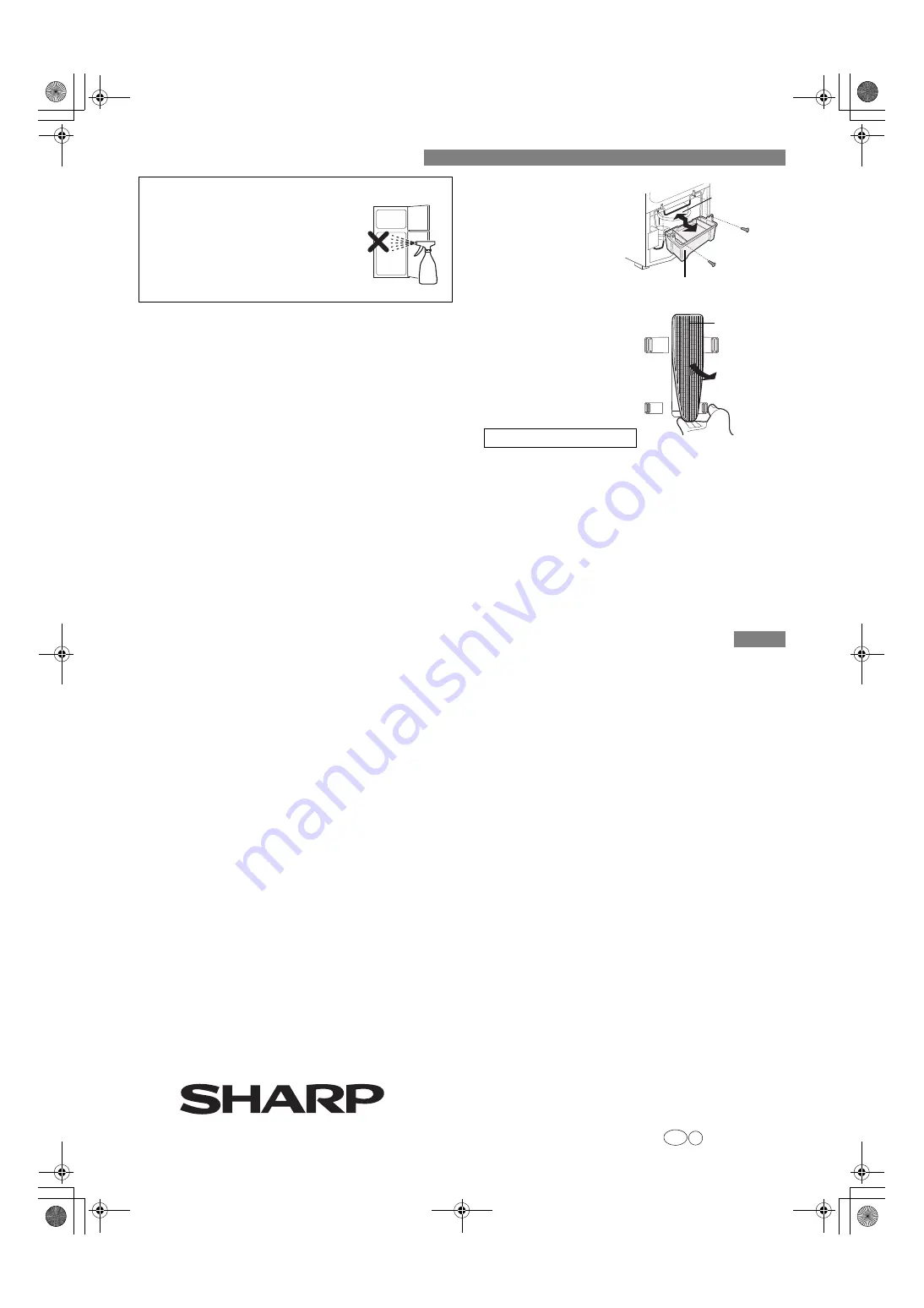

Evaporating pan;

How to remove/set

Remove the two screws to

take the Evaporating pan

off. Please pay attention to

the safety since the com-

pressor is very hot.

Replacing method

of the lamp bulb

1.

Unplug the refrigerator first

to prevent electric shock.

2.

Remove the Light cover.

3.

Replace the lamp bulb with

the same type.

Base E12, MAX 15W, T-20

Switching off your refrigerator

If you switch your refrigerator off when you are going away

for an extended period, remove all food, clean the interior

thoroughly. Remove the power cord plug from the power

socket and leave all doors open.

WHAT TO DO BEFORE YOU CALL FOR SERVICE

Before you call for service, check the following points.

IT IS NORMAL

for the refrigerator to produce the following

sounds.

•

Loud noise produced by the compressor when opera-

tion starts --- Sound becomes quieter after a while.

•

Loud noise produced once a day by the compressor

--- Operating sound produced immediately after auto-

matic defrost operation.

•

Sound of flowing fluid (gurgling sound, fizzing sound)

--- Sound of refrigerant flowing in pipes (sound may

become louder from time to time).

•

Cracking or crunching sound --- Sound produced by

expansion and contraction of inner walls and internal

parts during cooling.

•

Squeaking sound --- Sound produced by expansion and

contraction of internal parts.

IT IS NORMAL

that the outside of a cabinet may be hot

when touched. The hot pipe is in the cabinet in order to pre-

vent dew generation.

IF YOU STILL REQUIRE SERVICE

Refer to your nearest service agent approved by SHARP.

Compressor

Evaporating

pan

Light cover

SHARP CORPORATION

TINS-A986CBRZ 10KK TH 3

Напечатано

в

Таиланде

/

Printed in Thailand

12

(A986)_ENG-3版.fm Page 13 Thursday, September 16, 2010 4:42 PM