PRECISION MACHINE TOOLS

Ver 1 Maintenance Manual

31

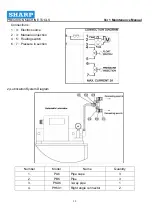

caution

:

1) Value of the input source current has to be the same as the one on the plague.

2) The wiring has to follow the instructions on the plaque to avoid damaging the oil pump.

3) Ground the ground wire.

4) A filter is installed on the inlet of the oil tank. Do not contaminate the manifold block

components.

5) Wash the filter whenever it is contaminated to maintain its function.

6) Do not drop oil, water or other onto the control circuit, or the control circuit may be

damaged.

7) Pay attention to the oil level when filling up the oil.

4-2 Spindle Bearing Lubrication

High quality lube oil is used for the spindle bearing, and it is good for high temperature and high

speed conditions. Its lubricating effect on the bearing is long-lasting without being too oily, and

therefore there is no need to add or to change the lube oil for a while. It is therefore cost-saving.

4-3 Guide way and Ball Screw Lubrication

The linear guide way of X, Y and Z axes and the ball screws are lubricated by a centralized

lubrication system which lubricates according to the set schedule. Machine operators must ensure

that the oiling machine has enough oil, as well as whether there is any abnormality.

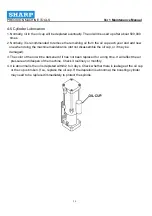

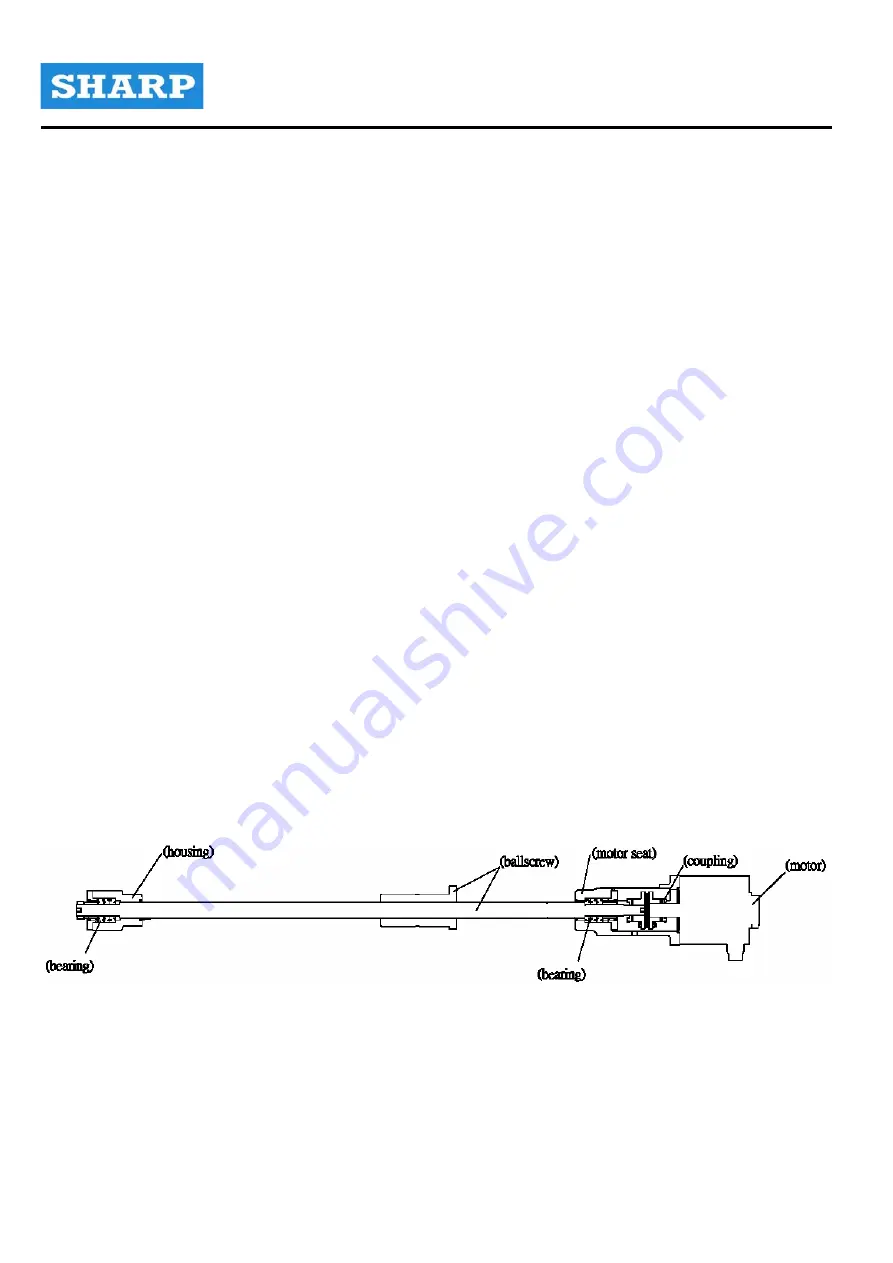

1) Lead Screw Lubrication

The bearing of the lead screw can be divided into the motor end and the housing end. Lube oil is

applied onto both ends for oil sealing. If the oil goes bad, dissemble these parts to wash the

bearing and reassembling them. Please contact the Company to have professionals checkup and

modification for you.

2) Guide way Lubrication

Guide ways of the workbench (X-axis), the saddle (Y-axis), the head (Z-axis), ball screws of the three

axes (X, Y and Z axes) and the nuts are lubricated by the automatic centralized lubrication system

in which an oil pump is located at the back of the machine.

Summary of Contents for SV2414

Page 1: ...SV2414 SVL2416 MAINTENANCE MANUAL ...

Page 4: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 4 Chapter 1 Routine Maintenance ...

Page 8: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 8 12 13 Coolant tank ...

Page 9: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 9 Machine precision check 20 21 ...

Page 11: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 11 5 6 7 Spindle oil temperature controller ...

Page 15: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 15 Chapter 2 The Spindle Unit ...

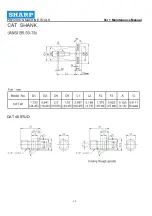

Page 17: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 17 2 2 Tool Shank and Broach Bolts ...

Page 18: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 18 CAT 40 STUD ...

Page 23: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 23 Chapter 3 The Air Compressor Unit ...

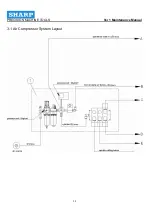

Page 24: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 24 3 1 Air Compressor System Layout ...

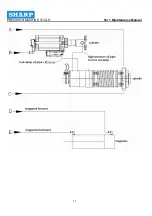

Page 25: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 25 ...

Page 28: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 28 Chapter 4 The Lubrication Unit ...

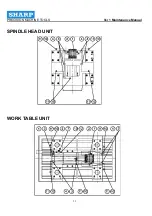

Page 33: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 33 SPINDLE HEAD UNIT WORK TABLE UNIT ...

Page 34: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 34 Saddle unit ...

Page 37: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 37 4 6 Lubrication Location ...

Page 38: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 38 Chapter 5 The Spindle Oil Cooling Unit ...

Page 39: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 39 5 1 Oil Cooling Pipeline Diagram ...

Page 42: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 42 ...

Page 44: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 44 ...

Page 47: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 47 Chapter 6 The Electrical Unit ...

Page 51: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 51 Chapter 7 Appendix ...

Page 59: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 59 ...

Page 60: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 60 ...

Page 61: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 61 ...

Page 62: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 62 ...

Page 63: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 63 ...

Page 64: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 64 ...

Page 65: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 65 ...

Page 66: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 66 ...

Page 67: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 67 ...

Page 68: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 68 ...

Page 69: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 69 ...

Page 70: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 70 ...

Page 71: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 71 ...

Page 72: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 72 ...

Page 73: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 73 ...

Page 74: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 74 ...

Page 75: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 75 ...

Page 76: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 76 ...

Page 77: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 77 ...

Page 78: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 78 ...

Page 79: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 79 ...

Page 80: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 80 ...

Page 81: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 81 ...

Page 82: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 82 ...

Page 83: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 83 ...

Page 84: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 84 ...

Page 85: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 85 ...

Page 86: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 86 ...

Page 87: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 87 ...

Page 88: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 88 ...

Page 89: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 89 ...

Page 90: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 90 ...

Page 91: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 91 ...

Page 92: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 92 ...

Page 93: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 93 ...

Page 94: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 94 ...

Page 95: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 95 ...

Page 96: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 96 ...

Page 97: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 97 ...

Page 98: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 98 ...

Page 99: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 99 ...

Page 100: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 100 ...

Page 101: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 101 ...

Page 102: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 102 ...

Page 103: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 103 ...

Page 104: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 104 ...

Page 105: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 105 ...

Page 106: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 106 ...

Page 107: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 107 ...

Page 108: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 108 ...

Page 109: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 109 ...

Page 110: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 110 ...

Page 111: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 111 ...

Page 112: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 112 ...

Page 114: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 114 7 5 2 Tool Magazine 1 Umbrella type ...

Page 115: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 115 ...

Page 120: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 120 ...

Page 121: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 121 ...

Page 127: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 127 7 5 4 Column 1 SVL2416 ...

Page 129: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 129 7 5 5 Base Plate 1 SVL2416 ...

Page 131: ...PRECISION MACHINE TOOLS Ver 1 Maintenance Manual 131 7 5 6 Saddle base Workbench 1 SVL2416 ...