UP-3301US

SERVICE PRECAUTION

– 18 –

5. Requirements for soldering circuit parts

To solder the following parts manually, follow the conditions described

below.

6. Note for handling of Touch panel

• The transparency of the touch panel is vitally important. Do not place

finger prints or moisture on the surface. When handling, use clean

gloves and masks.

• For handling, do not hold the transparent area, and do not hold the

heat seal connector section to assure reliability.

• Do not overlay touch panels. The edge may damage the surface.

• Do not put a heavy object on the touch panel.

• Do not apply strong shocks, and do not drop.

• When attaching the protection film, carefully check that no dirt exists.

• To clean dirt on the surface, use a dry, soft cloth or a cloth immersed

in ethyl alcohol.

• Check that the housing does not induce any stress to the touch

panel.

• Be careful not to touch the touch panel with tools.

• The heat seal section is easily disconnected. Be careful not to apply

any stress to the heat seal section when installing.

• The touch panel is provided with an air groove to make the external

and the internal air pressure equal to each other. If water or oil is put

around the air groove, it may penetrate inside. Be careful and keep

the air groove away from water and oil.

• Input is performed with fingers. Do not use hard objects to input

entries.

7. Note for handling the LCD assembly

• The LCD elements are made of glass. BE careful not to expose them

to a strong mechanical shock. Use extreme care not to break them.

• If the LCD element is broken and the liquid is seeps, do not lick it. If

the liquid comes in contact with your skin or clothes, immediately

clean with soap.

• Use the unit under the rated conditions to prevent against damage.

• Be careful not to drop water or other liquids on the display surface.

• The reflection plate and the polarizing plate can be easily scratched.

Be careful not to touch them with any hard object such as glass or

tweezers. Never hit, push, or rub the surface with hard objects.

• When installing the unit, be careful not to apply stress to the LCD

module. If excessive stress is applied an abnormal display or uneven

color may result.

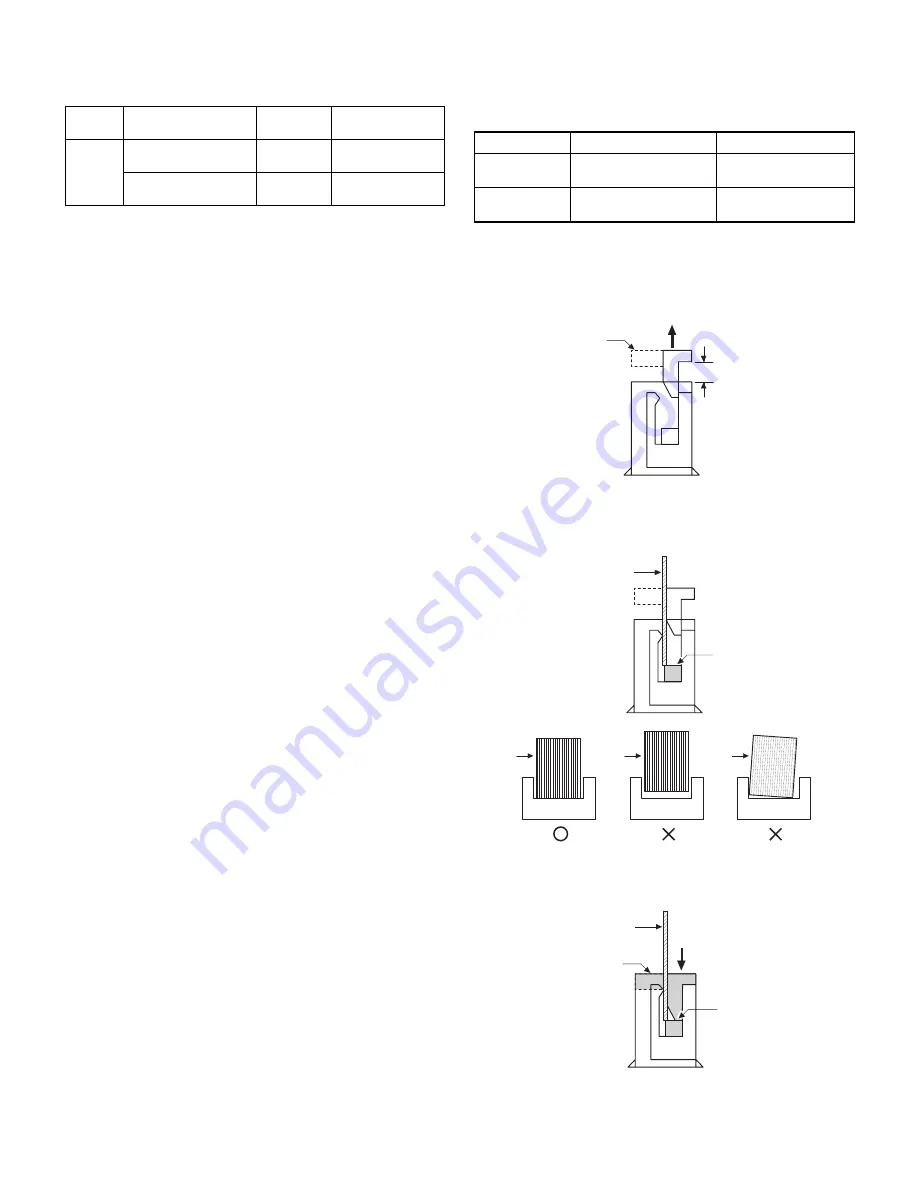

8. Cautions on handling connectors

When connecting or disconnecting the following connectors, follow the

procedures below.

1)

• How to Connect or Disconnect the FFC Connector

(1) Open the slider to the unlock position

The slider will open only up to a fixed height (about 1.2mm). If you

used force to pull up the slider further, it may be damaged.

(2) Insert the FFC

Insert the FFC firmly untill the FFC hits the bottom of the connec-

tor’s insulator.

(3) Close the slider to the lock position

Insert the FFC and then push the slider downward.

PARTS

NAME

PARTS CODE

LOCATION

CONDITIONS FOR

SOLDERING

Ceramic

oscillator

RCRMZ7002RCZZ

MAIN PWB:

X1 (8M)

270°/3sec.

RCRMZ7004RCZZ

MAIN PWB:

X2 (7.37M)

270°/3sec.

PARTS NAME

PARTS CODE

LOCATION

FFC

CONNECTOR

QCNCW7207RC4J

MAIN PWB: CN6

TOUCH PWB: CN5

FFC

CONNECTOR

QCNCW7183BH2F

MAIN PWB: CN1

Slider

1.2mm

UNLOCK

FFC

FFC

CONNECTOR

FFC

CONNECTOR

FFC

CONNECTOR

FFC

Slider

LOCK

Summary of Contents for UP-3301

Page 91: ...UP 3301US PWB LAYOUT 89 CHAPTER 9 PWB LAYOUT 1 MAIN PWB A side ...

Page 92: ...UP 3301US PWB LAYOUT 90 B side 8 CUSTOMER DISPLAY PWB ...

Page 93: ...UP 3301US PWB LAYOUT 91 2 IR PWB 3 LCD PWB A Side B Side 4 INVERTER PWB A Side B Side ...

Page 94: ...UP 3301US PWB LAYOUT 92 5 MOTHER PWB 6 N F PWB 7 TOUCH PANEL PWB ...

Page 95: ...UP 3301US PWB LAYOUT 93 ...

Page 111: ......